You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solid tires?

- Thread starter RustyKipper

- Start date

Chalo

100 TW

Eastwood said::wink:markz said:Some liners have actually caused flats.

I wonder how that would happen?

Chalo said:markz said:Some liners have actually caused flats.

They do it all the time. I've fixed more flats that were caused by tire liners than I've sold tire liners.

Interesting, do you have a bike shop?

I've worked in bike shops starting in 1992 and continuously since 2009.

Tire liners cause flats by chafing the tube at the edges and ends of the liner strip as the tire flexes. By the time the first puncture appears, there are many other places on the tube that are just about to let go.

Mr Tuffys are among the worst offenders because they have no taper at the ends of the strip to help mitigate chafing damage.

Your 1000 miles without yet suffering a puncture due to tire liners isn't remarkable; that's less than a month's riding for some pedal cyclists. However, it should be long enough for you to inspect your tubes and find damage caused by the tire liners.

There is a fault-free substitute for tire liners, which is to use a tire that includes similar protection built into the tire's casing (where it can't abrade the tube). Using a tire that has as much puncture resistance as you need is always a superior solution to using an add-on remedy that brings its own problems.

Chalo said:Using a tire that has as much puncture resistance as you need is always a superior solution to using an add-on remedy that brings its own problems.

I wish such a tire was made in a bicycle size! i've tried the thickest of them and they all fall short on a simple goathead penetration test done with a pin that's the exact length of the largest goathead i've seen. Usually 3-5mm short of preventing the puncture.

Nobody has tried this yet AFAIK but 22" BMX rims are becoming more popular and there's 18 x 2.25 and up lightweight motorcycle tires that will fit them. The end diameter would be close to 23" in bicycle wheel size. If we're talking about a full suspension bicycle where the rear shock could be lengthened a bit and the front shortened.. one could have, at least, a 23" in the rear and 26" in the front, and not have to run significantly shorter pedals.

Bike tire in a bike tire seems like a good idea until the inner tire slips. Possibly they could be fixed to each other using RTV or some other rubber type adhesive.

Since i am firmly in the recumbent camp using motorcycle tires.. these experiments are up to you upright bikers to partake in.

Eastwood

100 kW

- Joined

- Jan 13, 2021

- Messages

- 1,479

Chalo said:There is a fault-free substitute for tire liners, which is to use a tire that includes similar protection built into the tire's casing (where it can't abrade the tube). Using a tire that has as much puncture resistance as you need is always a superior solution to using an add-on remedy that brings its own problems.

Using both is better. I think the most practical solution is to use both and you will have less chance of getting a flat. Again I’m only speaking from my experience with this particular brand and there is zero damage to the tubes.

Chalo said:Mr Tuffys are among the worst offenders because they have no taper at the ends of the strip to help mitigate chafing damage.

All the liners I've used are tapered from Mr. Tuffys. I just replaced both tires and there what is zero chafing on the tubes. The outer edge of these inserts are made with a different type of rubber and the ends flare upwards slightly away from the tube preventing friction.

Chalo

100 TW

Eastwood said:Chalo said:There is a fault-free substitute for tire liners, which is to use a tire that includes similar protection built into the tire's casing (where it can't abrade the tube). Using a tire that has as much puncture resistance as you need is always a superior solution to using an add-on remedy that brings its own problems.

Using both is better. I think the most practical solution is to use both and you will have less chance of getting a flat.

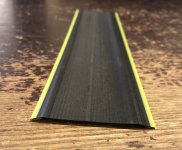

Nope. Here's today's installment. I was working on a sporty road bike with an oddly heavy front wheel. Turns out it had both a Tuffy and a thick thorn resistant tube in there. If this had been a normal thickness tube, it would have been cut through by now:

As it was, there was some air inside... but also the ride quality of a garden hose stuffed full of socks. The wheel barely bounced when dropped.

Trust me when I tell that you want enough flat protection, not way too much flat protection. It all comes at some cost. But it's best by far to use a tire with the amount of built-in protection you need, and not add other junk to your tire and tube. Add-on flat protection appeals to consumers' fascination with upgrades and enhancements, but they all have significant tradeoffs (or else they'd be standard issue).

I tried duct tape with some success. It is like a liner and didn't cause flats. My experience is that sidewalks, low psi tires and worn tires are a good recipe for puncture. I try to avoid such scenarios. High psi will make it closer to solid but with a bounce. What's goathead environment?neptronix said:I've tried liners and got tired of the flats they cause.

Yet another gimmick.

Slime/stans or more rubber are the only working answers for my goathead filled environment.

markz

100 TW

If that were to have torn the inner tube, would have taken many patches to fix that if it would have even been fixable out riding.

Chalo said:.jpg

Eastwood

100 kW

- Joined

- Jan 13, 2021

- Messages

- 1,479

Chalo said:Nope. Here's today's installment. I was working on a sporty road bike with an oddly heavy front wheel. Turns out it had both a Tuffy and a thick thorn resistant tube in there. If this had been a normal thickness tube, it would have been cut through by now:

Add-on flat protection appeals to consumers' fascination with upgrades and enhancements, but they all have significant tradeoffs

The appeal of these liners for me is protection not fascination with upgrades. As I mentioned before do a lot of urban riding on side walks and have ran through glass countless times without flats. Also do Aggressive mountain bike trail riding without any flats.

One deciding factor when I bought these liners was online reviews from multiple sources. There are several reviews with people that have thousands of miles with no punctures. In my situation 1000++ miles with the same results. I changed my tires around 4 weeks ago and there was nothing wrong with my inner tubes. So from my own experience i’ve had zero flats. I’ve gotten punctures before in the same areas that I ride so this liner seems to be a great shield.

However with Mr. Tuffys there are different size tire liners and they all look different so the ones I got don’t cause this chafing. For the liners that causes chafing i’ve heard of people sanding the edges down or heating it up with a lighter to smooth it out. Thankfully I haven’t had this issue.

It’s like that expression don’t throw the baby out with the bathwater. Because of isolated bad experiences we can’t deem that tire liners are always bad.

The liners I’m using are different than the picture you posted. The edges are tapered and angled away from the tube. It prevents chafing and friction on the outer edge. I’m using The version that’s for 27.5 plus tires.

Attachments

I can see that liner destroying inner tubes the same way my stop flats and mr tuffy's did.

Mine would consistently destroy the tube within 50-100 miles.

They'd stop the bastard goatheads fairly well though.

My best guess is that on occasion, the tire pressure drops and the tube or liner would shift internally and chafe under power.

..the bike i ran this on had a peak speed of 59mph and had 6kW of power, so go figure, right?

..but Chalo is seeing these same problems on pedal bikes.

.. i really think it would be worth experimenting with gluing a liner or another tire to the inside of another tire using RTV. It would prevent the inner slip issue. The rolling drag of the resulting tire would be between a bike tire and motorcycle tire.

If you used a liner, you could file it's edges and then make them seamless using RTV as well.

The best way to ensure the tire didn't have any imperfections would be to cure the RTV while the wheel is spinning continuously against a roller. IE, inflate the tube, set the cruise control to a slow speed, and let it spin on a bike trainer for at least 4 hours of the curing process.. and the rolling would likely even out imperfections.

Or perhaps you could put the inflated wheel in a fork and take it for a walk around the block after applying the RTV while pressing it against the ground.

My biggest concern about the tire in a tire or liner in a tire scenario is that the tire's weight and shape is perfectly balanced.

..in the meantime if you are lucky and tire liners aren't puncturing your tires, stick with the idea. But in no way could i trust them myself.

Mine would consistently destroy the tube within 50-100 miles.

They'd stop the bastard goatheads fairly well though.

My best guess is that on occasion, the tire pressure drops and the tube or liner would shift internally and chafe under power.

..the bike i ran this on had a peak speed of 59mph and had 6kW of power, so go figure, right?

..but Chalo is seeing these same problems on pedal bikes.

.. i really think it would be worth experimenting with gluing a liner or another tire to the inside of another tire using RTV. It would prevent the inner slip issue. The rolling drag of the resulting tire would be between a bike tire and motorcycle tire.

If you used a liner, you could file it's edges and then make them seamless using RTV as well.

The best way to ensure the tire didn't have any imperfections would be to cure the RTV while the wheel is spinning continuously against a roller. IE, inflate the tube, set the cruise control to a slow speed, and let it spin on a bike trainer for at least 4 hours of the curing process.. and the rolling would likely even out imperfections.

Or perhaps you could put the inflated wheel in a fork and take it for a walk around the block after applying the RTV while pressing it against the ground.

My biggest concern about the tire in a tire or liner in a tire scenario is that the tire's weight and shape is perfectly balanced.

..in the meantime if you are lucky and tire liners aren't puncturing your tires, stick with the idea. But in no way could i trust them myself.

As I've noted before in threads about flats, to stop this tube damage, all you really need to do is provide a sacrificial surface for the liner to wear, by taking an old tube (preferably a thick one) and cutting out it's valve stem along with the thicker area immediately around the stem on the inner circumference. Then slit this tube along it's inner circumference, and slip it over your actual tube that will be inflated. Install the tire liner inside the tire, then install this layered tube assembly.neptronix said:I can see that liner destroying inner tubes the same way my stop flats and mr tuffy's did.

Mine would consistently destroy the tube within 50-100 miles.

The disadvantage is that you have one more flexy layer in the tire which eats up energy as it rolls, and the tire is heavier.

But this combination does work, and is what I've used on CrazyBike2 and SB Cruiser (both heavy cargo bike/trike) for years, with the only problems typically being valve stem failures from crappy tubes (fixed on 20" wheels by using MC tubes with threaded stems (TR-4) that secure to the rims, and on 26" wheels by using CST brand tubes and another one I can't remember the name of now).

The wear on the sacrifical layer (which also acts as additional tube thickness vs punctures even along the sidewalls) is not noticeable before I wear a tire tread out (1-2000 miles ish, a year or two, depending on usage and tire; I use soft compounds for better grip (CST City in front for the last several years, Shinko SR714 in back) vs harder that would last longer).

I don't use a liner anymore on the rear ones; it hasn't been necessary, as the tires themselves are so thick they stop msot things, and have actually deflected nails to the side on their own when it's near the edge of the tread anyway. Plus, the wider the tire is with more surface area at the contact patch, the less likely it is the liner *could* deflect something anyway--the liners work better the skinnier the tire is, and/or the rounder the contact patch is, to help it do the deflecting.

But I do still use the extra "old tube as liner" method.

As Eastwood says, you may also be able to smooth the end-edges of the liner so they aren't sharp, but I never had any success with that with the Slime brand liners I used at the time.

Don't do this with a liner... i really think it would be worth experimenting with gluing a liner or another tire to the inside of another tire using RTV. It would prevent the inner slip issue.

I already did this years ago on DayGlo Avenger, for this same reason, with terrible results, using the Slime brand liners of the time. It will prevent the liner from being able to flex in a way that deflects stuff that's hard and sharp enough to puncture the liner and long enough to go thru it. Normally the liner works on these things by letting the sidewall edges lift up slightly and slide the tip of the pointy thing toward the sidewall instead of thru it and into the tube.

It did stop the liner from doing the snake thing and ending up "sinewaved" back and forth across the tread area (leaving unprotected areas of center tread), and from moving around and cutting the tube.

It did still stop goatheads and certain thorns and some small irregular road debris from puncturing the tube, however some of these would now be stuck in the RTV and tire (which never happened before gluing the liner down) and those not ground up by the action (glass and metal bits, etc) would be able to wiggle around and shred the tire itself until it herniated the area open by cutting the internal threads of the carcass, and then the tire could split up the sidewall and let teh tube hang out and be ripped open by the frame or the center kickstand mount or rim brakes, etc.

The worst, though was that it could not stop some nails (primarily roofing nails) and glass shards and mesquite thorns (usually those still attached to a piece of branch) and whatnot anymore--instead they would now go right thru the liner and the tube and the *back* of the tube and (in the case of nails) the RIM! actually now being stuck in or even thru the middle of the rim itself. The tube would be so damaged that it couldn't even be patched, so I'd be stuck walking if I didn't have a spare tube with me, along with a way to sand down and / or securely cover the rim damage (which could leave sharp edges on the hole or the deep scratch if it didn't actually puncture the rim).

I tried just gluing the ends of the liner together (without gluing it to the tire) so it couldn't change length or move the ends' edges against the tube, but the liner didnt' stay stuck to any glue I tried, including the RTV (though it did stick really well to the RTV on the tire itself; I don't know why...when I had to remove a liner from a destroyed tire I could pretty easily pull it out off the RTV).

I have used old *tires* as liners, but not glued them down because there was no need to. Just cutting off the bead (not the sidewall) and sometimes sanding the inner edges of the cut, then installing the tires inside the other tires, then installing the tube, then putting this mess on the rim and inflating, was sufficient. The inner tire would not shift around or damage the tube, unlike liners. IF you don't remove the bead, then the bead will wear and possibly release it's wire and THAT will take out your tube (and sometimes the actual tire!) but that's the only problem I ever had.

The catch is you have to use an inner tire that has a slightly smaller outer circumference than the inner circumference of the actual tire, just small enough to fairly closely fit against the inner walls and tread of the tire, or else it won't seat well even under inflation, and sometimes can roll badly until the actual tire's inner (usually) or outer (sometimes) circumference wears and exposes threads inside and then those can start breaking, and then the tire can come apart. (since you have an inner tire surface that's not catastrophic, but it will ride like crap (THunk thunk thunk on the rupture in the carcass) until you can change the tire).

You would also want to use as smooth a tread as possible on the inner tire (vs something like a knobby with knobs cut off, etc), for the closest smoothest fit against the inside of the other tire.

It might work fine to glue this inner tire against the outer tire, and perhaps it would help with rolling resistance. Never tried the experiment.

I've also never tried gluing the "old tube as a liner" onto either the tire or the tube (if I were going to do it I'd probably glue it to the tube, not the tire, then immediately inflate the system as an assembled wheel).

The best way to ensure the tire didn't have any imperfections would be to cure the RTV while the wheel is spinning continuously against a roller. IE, inflate the tube, set the cruise control to a slow speed, and let it spin on a bike trainer for at least 4 hours of the curing process.. and the rolling would likely even out imperfections.

I didn't have any issues with imbalance (well, not any more than the overlapped liner ends already caused), so you don't really have to worry about that. Not that I was going more than around 15mph on that bike, maybe 20 for short peaks here and there, but I don't think the RTV itself, if properly applied, will cause balance issues. Only a very thin layer needs to be applied to the liner, then stick it inside the tire and press it down, then insert the tube and inflate that, while it's all installed on the rim as normal--the inflated tube will apply even pressure around the tire for you.

The reflectors on the spokes, the valve stem, the not-very-balanced-manufacturing of the tires, etc, all made far more of a difference than the liner or the RTV did. Especially the tires, and especially the Kenda brand ones (which for me always had problems with the sidewalls, and with there being thicker tread rubber on some areas of every tire), and Innova (same imbalance problems), and another I can't recall at the moment. The CST and Maxxis didnt' have the imbalance problems to a significant degree, though they were not perfect either.

neptronix said:

I live in an area thick with those and back when I was riding MTBs I'd just use a standard tube with 100-150ml of Slime. Automotive Slime, not the bicycle stuff. It worked reliably at MTB pressures. Tyres would be studded with thorns where jacks broke off or green dots. If the tyre went down overnight I'd spin the tyre and reinflate.

My road bikes are tubeless, but pressures are too high for the sealant to be used like this. It'll slow it down enough though and when I get home I pull the tyre off and patch the hole. It's a road bike though and I avoid putting it through nasty stuff. Staying on the main road surface avoids it all.

Schwalbe Marathon Plus (liner between case and tread) are effective against those thorns. The con is I didn't like the rolling resistance and feel in road bike sizes... but I actually pedal my bike. Assist speed limit is about 2kph below my human powered pace.

In large sizes and low pressures add Slime in the tube.

markz

100 TW

I don't mind the weight penalty of moped tires, tubes and rims knowing I won't get a flat ever with that setup.

Someone who likes to pedal would have a dilemma, but maybe its tubeless for them.

I would really love to know if going tubeless would help me out, got countless flats. Heck even got one yesterday on a brand new tube and tire. Thats the way it goes after not even 50 miles of riding. I never bothered to figure that flat out.

Someone who likes to pedal would have a dilemma, but maybe its tubeless for them.

I would really love to know if going tubeless would help me out, got countless flats. Heck even got one yesterday on a brand new tube and tire. Thats the way it goes after not even 50 miles of riding. I never bothered to figure that flat out.

TDB said:My road bikes are tubeless, but pressures are too high for the sealant to be used like this. It'll slow it down enough though and when I get home I pull the tyre off and patch the hole. It's a road bike though and I avoid putting it through nasty stuff. Staying on the main road surface avoids it all.

That might explain why slime has failed to do the job for me numerous times. I have full suspension bikes and i always use the maximum rated tire pressure for best 'watt economy'.

TDB said:Schwalbe Marathon Plus (liner between case and tread) are effective against those thorns. The con is I didn't like the rolling resistance and feel in road bike sizes... but I actually pedal my bike. Assist speed limit is about 2kph below my human powered pace.

In large sizes and low pressures add Slime in the tube.

The marathon plus is my favorite "puncture proof" tire. But only offers 7mm of total rubber. I've pulled goatheads that are 11m long out of flat marathon plus equipped wheels though. I've had the same 'flat tire every 10 miles' experience riding on the street exclusively here in Utah.

There's been instances where i've ridden off road and ended up with around 100 goatheads hooked into a marathon plus that's slowly going flat, within 1 mile of riding.. turns out that of those 100, only 4 had punctured the tube because they were long enough.

Exhibit A: 1 mile of offroad. And yes, the tires went flat.

markz

100 TW

Crazy!

And thats in Utah (650 miles directly South from me), where are these goat heads because I have never seen them. Are they in places 325 miles south of me: Montana, Northern Idaho, Washington?

What do the goat heads come off of, my original guess would have been Cactuses

but its Goat Head weeds or goat's head plant (Latin name is Tribulus terrestris)

https://dengarden.com/gardening/goat-heads-puncture-vine-sand-burr-removal

https://www.invasive.org/browse/subinfo.cfm?sub=3937

Interesting how the title is "puncturevine Tribulus terrestris L."

puncturevine

Well I wonder why its spuratic in parts and not in others.

And thats in Utah (650 miles directly South from me), where are these goat heads because I have never seen them. Are they in places 325 miles south of me: Montana, Northern Idaho, Washington?

What do the goat heads come off of, my original guess would have been Cactuses

but its Goat Head weeds or goat's head plant (Latin name is Tribulus terrestris)

https://dengarden.com/gardening/goat-heads-puncture-vine-sand-burr-removal

https://www.invasive.org/browse/subinfo.cfm?sub=3937

Interesting how the title is "puncturevine Tribulus terrestris L."

puncturevine

Well I wonder why its spuratic in parts and not in others.

neptronix said:

Their native habitat is desert-like climates.. anywhere that trends towards dry and sunny will be plagued by them. I'm surrounded by 3 counties that have them everywhere.

Bike riding is only popular here with professional cyclists and broke people. There's also very little bicycle infrastructure.. you may have a bike lane for a mile.. but then suddenly it disappears and your choice is to ride in goathead infested dirt or on a 45mph street.

Not a fun place to ride!

Bike riding is only popular here with professional cyclists and broke people. There's also very little bicycle infrastructure.. you may have a bike lane for a mile.. but then suddenly it disappears and your choice is to ride in goathead infested dirt or on a 45mph street.

Not a fun place to ride!

marka-ee

100 W

- Joined

- Mar 24, 2020

- Messages

- 173

On my scooter which always gets flats I decided to coat the inside of the tire with silicon sealer clear caulk. I figure it adds some extra distance before the intruder gets to the tube. So far so good. I also put Stans in the tube, but I have found that Stans seems to turn 'runny' after a while and can no longer do any hole sealing. Looks like milk coming out and doing nothing after a few mo. in there.

Interesting. A certain weight/hardness of RTV may also work too.. if you can get the layer to be nice and even. I may even experiment with that myself, as motorcycle tires do come with notably increased drag.

Amberwolf laid down some pretty useful info here.

Amberwolf laid down some pretty useful info here.

MTB pressuresI was talking about are to about 60psi. Narrow road pressures... 100+. Road tyres will usually stabilise around 80psi with sealant in a puncture.

Stans is a good bead sealant for tubeless road tyres, but is generally a poor puncture sealant. It also separates and hardens inside the tyre within months. I wear through tyres in about four weeks so that isn't a problem

Caltrop, jacks, goat heads are the same and as widespread as here. But you breed them bigger and badder in the USofA. You win. lol

Silicone is very heavy. Maybe butyl rubber or foam rubber.

You have the means to spin the wheel to get an even coating if you can keep the air in it. Preparation and don't ride it until it is fully cured.

Or... Bond a super heavy tube tube to the inside of a tyre... inflate it inside the tyre with tyre cement. Remove the tyre from the rim and cut the tube away flush with the bead to avoid edges that will erode an inner tube. Repeat if necessary.

Add a bottle of sealant and 200g of steel shot to the tyre. The shot will distribute itself to balance the tyre when it is moving.

All of that extra rubber and sealant and shot will be a bitch to pedal, but hey, pedals are only for show.

Stans is a good bead sealant for tubeless road tyres, but is generally a poor puncture sealant. It also separates and hardens inside the tyre within months. I wear through tyres in about four weeks so that isn't a problem

Caltrop, jacks, goat heads are the same and as widespread as here. But you breed them bigger and badder in the USofA. You win. lol

Silicone is very heavy. Maybe butyl rubber or foam rubber.

You have the means to spin the wheel to get an even coating if you can keep the air in it. Preparation and don't ride it until it is fully cured.

Or... Bond a super heavy tube tube to the inside of a tyre... inflate it inside the tyre with tyre cement. Remove the tyre from the rim and cut the tube away flush with the bead to avoid edges that will erode an inner tube. Repeat if necessary.

Add a bottle of sealant and 200g of steel shot to the tyre. The shot will distribute itself to balance the tyre when it is moving.

All of that extra rubber and sealant and shot will be a bitch to pedal, but hey, pedals are only for show.

Similar threads

- Replies

- 45

- Views

- 1,418

- Replies

- 20

- Views

- 2,937

- Replies

- 12

- Views

- 10,767