Methy,

Feel like sharing some artwork for component / trace and silkscreen for those of us with Etch tanks and time on our hands? I already presume the answer is No and I fully understand.

I had 9 prototypes made and I am sure there are mistakes. I will just send you a unit to play with. Once I figure out what needs changing my next run will be 100pcs. You have always been an enthusiastic participant - I will gladly send you a few at my cost.

As far as my design - it is so dead simple that you could duplicate it in only a few minutes. I will share the eagle files tho if you want them (after I find any bugs etc)

I'm going to be applying my very first contactor in a slightly different manor... I've had an EMC1200 break (I was a dunce and connected the leads backwards) which led to damage to the voltage sensing and relay (yea, that's their surge control and HV output disconnect method)... you would think it would have survived a reverse polarity connection but nope...

So I figure since everything else is still fine, I'll remove the relay and brake traces for all the input pack voltage sensing (which I checked, only manages the relay not the charger voltage that's a traditional TL494 IC chip) and whalla... guess I could do it now already based on the schematics you posted but you do such nice board design.

Oh, I'm really glad you decided to go with the 2S lipo it really is the way to go after weighing all the options (unless isolated DC->DC switching conversion can be done at pack level voltage of 100v) which just gets more complicated and also expensive.

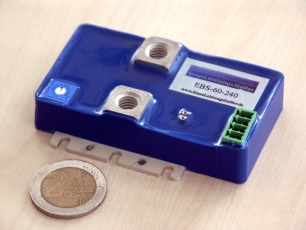

I populated a couple boards. One with nano-tek 2S, one with 40mAh coin 2S, and one with 240mAh coin 2S.

Have you considered this approach in a new version of your LTC BMS (that would be version 5 right)? If stacked self powered 6803/4s were controlled by an isolated MCU using this approach it would make voltage potentials a non issue for the MCU / Brain portion.

I dont even want to think about the LTC BMS. Folks have no idea how much effort went into V4 and it basically got tossed in the bin. I was so worn down after that all I could muster was the LVC boards.

Just an idea, worthless unless implemented.

A few more ideas:

1.) I can't recall if I saw an optocoupler place on board with this in your art / schematic. I would say it could be useful for many purposes your design will be adaptable to, perhaps include a place for it to interrupt the gate drive via an NPN triggered by the optocoupler - in non switch form, no NPN or opto need be placed but it would be a nice option.

You are getting into GizMo territory. Gizmo does all that shit - has Opto output throttle control, RTC, uSD, A-D's, D-A's, 8 temperature probes, current monitoring (dual hall), blah blah. This unit is the KEEP IT SIMPLE device. Everything else goes on Gizmo.

2.) How difficult would reverse polarity detection be to implement, in it's crudest but effective form? As I've just learned properly done worth it's weight in gold?

It is done with the thermal switch. If you apply voltage backwards it does nothing to the circuit (because the circuit runs on its own power) What it does do is short through the body diode of the mosfets (meaning it is on all the time) and if any appreciable amount of current flows the mosfets will get hot and flip the thermal breaker. So long as a user toggles the system after hooking up the high power I dont think there is really any problem with hooking it up backwards.

If I were to "do something" about it - it would be to put a second pair of fets on the board to make it truly bi-directional

3.) Have you considered making this an Arduino Shield? It's nearly pass through in stacking terms (one optically isolated pin triggers ON/OFF right) - this would make a fantastic shield much more reliable than Relay shields, more efficient and ... well not only would I purchase if it had been available (I've made my own based on one of your later schematics, for my own use prototyping) but I know 3 people who would also buy a minimum of 1 and 2 people who design mobile car stereos (think IASCA style competition systems) not to mention a few HAM and PACKET radio operators who would love to be able to replace their solid stage control boards. - Just a thought!

Gizmo is my arduino shield. For a dozen reasons this cant be a shield... power being at the top of the list.

A few more questions:

What would reverse biasing do to this current incarnation of the circuit - in theory of proper operation it should block voltage and do nothing but what would be the outcome?

Nothing - the current would just flow through the body diode of the fet and the switch would be rendered useless until polarity is reversed.

Patrick as always you have far outdone yourself, not in the aspects of the technical challenge of a Solid State Contactor (I'd loose the precharge control for charge delay) but more in your past, present and undoubted future contributions to the eBike cause but more importantly to the cause of sharing knowledge and empowering others, I for one Applaud you !

Warm Regards,

Mike