By the way, the controller is easy to remove from the case, just remove the two screws at the other end, then the screws on one side that hold it to the heatsink, it then slides out on the cable side, you just need to remove the end cap like you have done on the pcb end, the whole thing slides out as one unit then. This is a common problem on the Adaptto controllers, iv seen it many times on the Russian forum as well as here, its just a protective resistor, so there has been a short at some point. The only problem with sticking it on the end of a piece of wire like you have is its going to change the resistors value. The like for like replacement is a 3R9 or 3.9 ohms, sorry I cant remember the smt size, as I ended up buying all sizes and got the one that fitted, but I think its the 4mm size. There is apparently a range of values you can use, but I just replaced mine with a 3.9 in the end, as the 2.2ohm was making the controller do odd things sometimes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carbon Fiber E-Frame built ! by Doc

- Thread starter Doctorbass

- Start date

Doctorbass

100 GW

crea2k said:By the way, the controller is easy to remove from the case, just remove the two screws at the other end, then the screws on one side that hold it to the heatsink, it then slides out on the cable side, you just need to remove the end cap like you have done on the pcb end, the whole thing slides out as one unit then. This is a common problem on the Adaptto controllers, iv seen it many times on the Russian forum as well as here, its just a protective resistor, so there has been a short at some point. The only problem with sticking it on the end of a piece of wire like you have is its going to change the resistors value. The like for like replacement is a 3R9 or 3.9 ohms, sorry I cant remember the smt size, as I ended up buying all sizes and got the one that fitted, but I think its the 4mm size. There is apparently a range of values you can use, but I just replaced mine with a 3.9 in the end, as the 2.2ohm was making the controller do odd things sometimes.

Thanks for these advices

Yeah I only had a 4mm resistor available for the same value ((2R2) 2.2 ohm) but I guess that if it act like a fuse it would be good to keep the same size (wattage) to keep the same fast blow time to keep protecting the other components. I have opened my 2 max-E controller already and yes these are easy to open as well.

Doc

Doctorbass

100 GW

Spring is coming fast.!!..

..and about 3 month to go before to be able to ride my NYX bike!

I'm working on it a little bit everyday to install and try various parts on it.

This frame is so easy to work with !! 8) It's a really big step since my very firsts ebikes... The trek 970, the Mongoose Blackcomb, the Giant... I just think about all that timethese dozens of hours i have spent to try various configurations and fabricate all the custom parts... Damn!! all that just to have the battery on the bike to a "better" place than on a rear rack !! :lol:

all that just to have the battery on the bike to a "better" place than on a rear rack !! :lol:

Now with that NYX frame, every parts have their place and fit perfectly easy and keep an awsome look that is far beffer than the Mad Max previous style i had with duck tape !! I also like the fact that the frame have up to 16L of volume to install battery and is still narrow to keep a more bicycle look than motorcycle, plus it leave great place for knee when pedaling without hitting the frame.. so you dont need to pedal like if you would have a 10 inch cucumber in your ass to avoid your knee to interfere with the frame width 8) This sometime become a problem when frame are too wide. I ecpect that in offroad/cross country driving this will help to manouver the bike!

I also like the fact that the frame have up to 16L of volume to install battery and is still narrow to keep a more bicycle look than motorcycle, plus it leave great place for knee when pedaling without hitting the frame.. so you dont need to pedal like if you would have a 10 inch cucumber in your ass to avoid your knee to interfere with the frame width 8) This sometime become a problem when frame are too wide. I ecpect that in offroad/cross country driving this will help to manouver the bike!

I am working on the adaptto BMS now. It will be installed on the back of the top cover of the frame. I will be able to see all the 22 bms led thru it when charging.

Pictures comming soon!

Doc

..and about 3 month to go before to be able to ride my NYX bike!

I'm working on it a little bit everyday to install and try various parts on it.

This frame is so easy to work with !! 8) It's a really big step since my very firsts ebikes... The trek 970, the Mongoose Blackcomb, the Giant... I just think about all that timethese dozens of hours i have spent to try various configurations and fabricate all the custom parts... Damn!!

Now with that NYX frame, every parts have their place and fit perfectly easy and keep an awsome look that is far beffer than the Mad Max previous style i had with duck tape !!

I am working on the adaptto BMS now. It will be installed on the back of the top cover of the frame. I will be able to see all the 22 bms led thru it when charging.

Pictures comming soon!

Doc

kudos

10 kW

Does anyone know the internal width of the battery compartment ?

Kudos

Kudos

Doctorbass

100 GW

kudos said:Does anyone know the internal width of the battery compartment ?

Kudos

I remember this is a little bit more than 4 inches. I will measure precisely for you at the lunch time. :wink:

Doc

Bison_69

100 W

empty

80for20

10 W

Hi there DB,

I'm trying to puzzle through whether or not a schlumpf drive could be installed on this bad boy. Any idea?

I'm trying to puzzle through whether or not a schlumpf drive could be installed on this bad boy. Any idea?

Doctorbass

100 GW

15236 said:Hi there DB,

I'm trying to puzzle through whether or not a schlumpf drive could be installed on this bad boy. Any idea?

Actually I really don't know because I have never experienced these schlumpf drive.. in fatc that is the very first time I'm hearing about their existence! :lol:

But these look fantastic when it coe to driving at high speed and this avoid you to pedal at crazy rpm to be able to push some pedal power!

here is the link I have found to discover what are schlumpf drive:

http://www.schlumpf.ch/hp/schlumpf/faq.getriebe.engl.htm

I suggest contacting the guys at NYX .. they answer pretty fast. :wink:

Doc

15236 said:Hi there DB,

I'm trying to puzzle through whether or not a schlumpf drive could be installed on this bad boy. Any idea?

Hi 15236,

schlumpf planetary gear system is a really great system. Unfortunately, the NYX 2015 has a bottom bracket shell larger than standard bikes, similar to fat bikes. Schlumpf drive fits only for widths between 68mm and 72mm which is too small for our frame. However, we are taking your comment into account and will work on that.

Thanks again,

C.Baker

NYXBikes said:[ Schlumpf drive fits only for widths between 68mm and 72mm which is too small for our frame. However, we are taking your comment into account and will work on that.Code:

Maybe an alternative will work: http://endless-sphere.com/forums/viewtopic.php?f=3&t=66427

80for20

10 W

@db - Thx

@nyxbikes - Bummer

@striker54 - Thx, I'll check it out.

@nyxbikes - Bummer

@striker54 - Thx, I'll check it out.

Doctorbass

100 GW

kudos said:Does anyone know the internal width of the battery compartment ?

Kudos

OK sorry for the delay, I have measured the battery acces dimensions and the width is 108mm by 205mm lenght

Doctorbass

100 GW

I'm touching wood guys!

Yesterday I have found probably the lastest brand new Doubletrack 24" 36 holes rim on earth available!!

I got it with two brand new 24 X 3 Vuelta branded DH tires and 2 brand new DH Schraeder valve tubes for 105+ shipping!

I really like these rims, they are strong and lightweight! the tires are similar to the Arrow racing I have on my DH comb and that was on the stealth bomber.

http://www.ebay.ca/itm/321651325468

Doc

Yesterday I have found probably the lastest brand new Doubletrack 24" 36 holes rim on earth available!!

I got it with two brand new 24 X 3 Vuelta branded DH tires and 2 brand new DH Schraeder valve tubes for 105+ shipping!

I really like these rims, they are strong and lightweight! the tires are similar to the Arrow racing I have on my DH comb and that was on the stealth bomber.

http://www.ebay.ca/itm/321651325468

Doc

kudos

10 kW

Doctorbass said:kudos said:Does anyone know the internal width of the battery compartment ?

Kudos

OK sorry for the delay, I have measured the battery acces dimensions and the width is 108mm by 205mm lenght

Thanks for the info DB.

Kudos

Tommy L

100 kW

Subscribed!

A lot of thought went into this frame.

But very surprised they missed the Schlumpf drive

A lot of thought went into this frame.

But very surprised they missed the Schlumpf drive

I don't want to cross-promote, but if you have questions regarding the NYX 2015 Frame kit, you can directly ask us on this thread and it will be a pleasure to answer you:

http://endless-sphere.com/forums/viewtopic.php?f=31&t=66411

We have developped this frame for you guys, so all comments and suggestion are more than welcome.

http://endless-sphere.com/forums/viewtopic.php?f=31&t=66411

We have developped this frame for you guys, so all comments and suggestion are more than welcome.

Allex

100 MW

Doc, thank you for this interesting Build thread. What can you say about those WB forks. They are something of a dark sheep, I never really seen any review comparisons with other forks. Do you know how they are in comparison to Fox/Zocchs, Are they worth the high price?

Doctorbass

100 GW

Allex said:Doc, thank you for this interesting Build thread. What can you say about those WB forks. They are something of a dark sheep, I never really seen any review comparisons with other forks. Do you know how they are in comparison to Fox/Zocchs, Are they worth the high price?

Allex, I have one of my friend who was ready to pay me hundreds of dollars to buy mine ( used) This fork came from a salvaged Zero X 2010 EXTREME version.As well it is a mtb fork but from the hundreds of km i made with it i am satisfied with !. Apparently this is a really good rated fork. Mine is a fully adjustable.

Doc

Doctorbass

100 GW

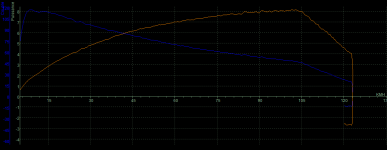

DYNO test with the NYX bike frame kit !

Here is 2 little DYNO test to validate the torque endurance of the torque arm design. Total torque we measured this day was 120 lb-ft and 10.5hp

Please note that we forgot to correct the negative torque and power(hp) from the friction of the dyno and wheel( calibration) so the dyno was pesimistic by about 20% on teh torque and power

btw it revealed that a single fast wound X5 motor can do easy 10.5hp and still have room for abnother 3-4 hp before saturating ! we had 10.5kW and 338A phase current and 130A batt current max limited by controller setting and gotr 10.5 hp = about 0.75% eff at that power

The torque plate incuuded with this frame never moved or loosen these hold very tight and axel torque is well distributed on the swing arm end design

[youtube]4QVazIxtNwc[/youtube]

Doc

Here is 2 little DYNO test to validate the torque endurance of the torque arm design. Total torque we measured this day was 120 lb-ft and 10.5hp

Please note that we forgot to correct the negative torque and power(hp) from the friction of the dyno and wheel( calibration) so the dyno was pesimistic by about 20% on teh torque and power

btw it revealed that a single fast wound X5 motor can do easy 10.5hp and still have room for abnother 3-4 hp before saturating ! we had 10.5kW and 338A phase current and 130A batt current max limited by controller setting and gotr 10.5 hp = about 0.75% eff at that power

The torque plate incuuded with this frame never moved or loosen these hold very tight and axel torque is well distributed on the swing arm end design

[youtube]4QVazIxtNwc[/youtube]

Doc

Attachments

Allex

100 MW

Now I want to see some comparison Dyno with the QS/Cro motor!

Ohbse

10 kW

Nice work Doc, cool to see some actual testing of a high performance bike! It's definitely dishing out some serious torque, I guess it's incredibly unlikely to see loads like that in use on the street as you'd loop it over well before 100lb/ft could be applied to the ground.

As well as agreeing with Allex that a comparison with Cro/Qs would be awesome I have a little bit of a wish list for other testing if ever you get the opportunity..

Effect of PWR timing on wheel torque - Dyno is the only real way to quantify an improvement as the 'butt dyno' is not going to be much help at this power to weight level. How much advance is beneficial? At what point does torque go DOWN? Does this have a negative effect on efficiency? Initial timing etc could also be 'tuned' for both power and efficiency ideal compromise using a dyno for comparative data.

OVS - my understanding is this could potentially extend your power curve to a higher RPM limit before reaching the 'knee' we see in the graph. In your case this probably would not assist in the real world as your KV is so high, meaning you would be aero limited well before this effect would be the bottleneck, however it's very applicable for people running a Cromotor with standard KV over 70 km/h.

More current! There have been examples of russian guys tuning beyond the inbuilt limitations. Never has pushing beyond the limits been so easy for you! just flash unlocked firmware and away you go. Key to keeping this alive is thermal management, a topic you no doubt know a lot about. There's good opportunity to greatly increase thermal mass and ability to reject heat from the FET's, perhaps even internal ventilation to assist with other components longevity. Additional caps, Upgrade of phase wires to 8ga etc all possible to increase power potential. 180 amps battery, 400 phase should truly stretch your motor to the limit.

I'm sure you're busy and may not have a chance to do all this, but perhaps somebody does. When I receive my Max-e back from Russia I will see if I can locate a suitable dyno locally and do some testing of my own

As well as agreeing with Allex that a comparison with Cro/Qs would be awesome I have a little bit of a wish list for other testing if ever you get the opportunity..

Effect of PWR timing on wheel torque - Dyno is the only real way to quantify an improvement as the 'butt dyno' is not going to be much help at this power to weight level. How much advance is beneficial? At what point does torque go DOWN? Does this have a negative effect on efficiency? Initial timing etc could also be 'tuned' for both power and efficiency ideal compromise using a dyno for comparative data.

OVS - my understanding is this could potentially extend your power curve to a higher RPM limit before reaching the 'knee' we see in the graph. In your case this probably would not assist in the real world as your KV is so high, meaning you would be aero limited well before this effect would be the bottleneck, however it's very applicable for people running a Cromotor with standard KV over 70 km/h.

More current! There have been examples of russian guys tuning beyond the inbuilt limitations. Never has pushing beyond the limits been so easy for you! just flash unlocked firmware and away you go. Key to keeping this alive is thermal management, a topic you no doubt know a lot about. There's good opportunity to greatly increase thermal mass and ability to reject heat from the FET's, perhaps even internal ventilation to assist with other components longevity. Additional caps, Upgrade of phase wires to 8ga etc all possible to increase power potential. 180 amps battery, 400 phase should truly stretch your motor to the limit.

I'm sure you're busy and may not have a chance to do all this, but perhaps somebody does. When I receive my Max-e back from Russia I will see if I can locate a suitable dyno locally and do some testing of my own

liveforphysics

100 TW

Doctorbass said:DYNO test with the NYX bike frame kit !

Here is 2 little DYNO test to validate the torque endurance of the torque arm design. Total torque we measured this day was 120 lb-ft and 10.5hp

Please note that we forgot to correct the negative torque and power(hp) from the friction of the dyno and wheel( calibration) so the dyno was pesimistic by about 20% on teh torque and power

btw it revealed that a single fast wound X5 motor can do easy 10.5hp and still have room for abnother 3-4 hp before saturating ! we had 10.5kW and 338A phase current and 130A batt current max limited by controller setting and gotr 10.5 hp = about 0.75% eff at that power

The torque plate incuuded with this frame never moved or loosen these hold very tight and axel torque is well distributed on the swing arm end design

[youtube]4QVazIxtNwc[/youtube]

Doc

That is roughly exactly the HP and torque in the flaming hubmotor dyno video.

Similar threads

- Replies

- 0

- Views

- 315

- Replies

- 5

- Views

- 1,237

- Replies

- 11

- Views

- 1,123

- Replies

- 21

- Views

- 1,074