amberwolf said:

I think I see what you're talking about.

First, are both the motor axles fully seated in the dropout? If either one is slightly not, then it will make the fork look funny because the wheel is tilted. This would also explain braking problems, becuase the rim surfaces can't be flat to the pads if the wheel is at an angle.

At this point and at the time of originally posting this, it was seated properly. When installing the second torque arm from Grin i mistakely didnt fully seat the axel, but fixed this before heading out. BEFORE that though, lets say the first 15 miles, it could have very well been misaligned.

amberwolf said:

Does it look normal without the motor in it (with the regular wheel instead)? Did the motor have to be pushed into the dropouts. spreading the fork? If so, the motor is too wide for the dropouts, and the fork happens to be sligthly easier to bend on the fork leg that is sticking out more.

If it's the same either way, then it's just the fork itself, either designed that way or a flaw in manufacturing.

Now, on the gap between axle flats and dropout sides: That shouldn't be possible, unless the dropouts are spread out. Was this gap present originally? If not, it means the axle is rocking in the dropouts and is not mounted correctly, that the torque arms are not mounted right or not tight enough (meaning, the hole in the arm is too large so teh axle can move in it, instead of being a tight fit).

If the gap was there originally, then either the motor axle is way skinnier than I've ever seen (10mm between flats is normal), or the dropouts were already bent/ spread, or were cut or ground out for some reason. (regular wheel axles are 9 or 10mm).

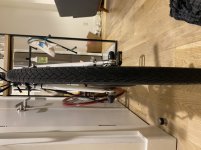

As of now, the fork does not spread when reinstalling the front motor wheel, but thats not to say it hasn't stretched already. I had some interesting findings when installing the original wheel. (see photos)

1. The drop outs are bent and the drop out that originally did not have the torque arm is about 1/8th of an inch wider

2. The fork seems to be bent to the drivetrain side of the bike

3. as you can see from the photos when putting on the original rim the brakes that have been centered for the motor wheel is significantly off centered from its original position

I wonder what could have caused this, I am thinking that it could be a few things

1. poorly installed original torque arm

2. original torque arm wasn't strong enough

3. the motor axels were never seated correctly

Question: without swapping out my fork and having installed the Grin v2 torque arm securely would this bike still be safe to for testing? (I am still trying to figure out a good acceleration time I would like to shoot for)

amberwolf said:

Since your fork ins't suspension, then it cant be bushings causing the flex, so it's still possibly a loose headset. The fork may have some forward/backward flex in it, that's normal and desirable for nonsuspension forks like that (helps with some bumps, etc).

not 100% sure if my headset is loose, but it feels pretty snug?

amberwolf said:

How quick an acceleration do you need? CrazyBike2, with about 4kw of power in 2WD hubmotors, did about 4 seconds to 20MPH, at something like 400lbs with me on it and some stuff. I'd have to use the simulator to see how much torque it actually had.

If you know the accleration time, and the mass, you can determine approximate torque needed to do that. THen you can look at the torque a motor is designed to do at a specific voltage and current, in what wheel size, and see if that meets your needs.

This week is super busy for me at work and I haven't been able to test as much as I'd like to but I was able to do 5 runs from 0-20 mph on a smooth flat road. I used "GPS race timer" from the app store on iPhone and here are the results from 0 with no pedaling level 5 (max) 100% throttle:

1. 11.6s 200ft.

2. 10.3s 223ft.

3. 10.9s 243ft.

4. 10.9s 217ft

and the last run i started with about 3 revolutions on the pedals

5. 7s 167ft.

I wish I had more time to test, but I did find this very interesting. An issue I ran into with the Ebikeling kit is that the PAS sensor wont fit on my BB so I have been riding and testing throttle only. I feel as though I cant accurately gauge how powerful of a motor I would need for the acceleration I would want because once I do install a PAS sensor, which is must for the future of this build, I will most likely be using it with the PAS more often than not.

THE NEXT STEP:

The Wyatt Street King has always been dear to my heart, but ultimately never fit me right (too big) and with the fork needing replacing presumably, I have decided I will replacing it with a new donor. With the added weight of a beefy pack and being that I am a heavier guy I think i may appreciate a bike with a front suspension or maybe a fat bike. Leaning towards a hardtail, I really like the look of a battery mounted underneath the down-tube (although not necessary) and curb hopping

...so I want something tough as nails that I can not worry about beating up in terms of hard urban riding (feels weird typing this, but its the easiest way to describe it!...not sure if it's the right move, and this is just my initial thought, but I find think they’re both really cool looking bikes and aesthetics are a big deal to me.

Questions regarding choosing a donor:

1. Being that i am going to be riding around the city, I would be better off with a hardtail over a full suspension bike, right?

2. With all the added weight of the kit onto the bike would i be able to fit a rear rack onto a hardtail?

3. I wouldn't be loading it up too often and like i said it would be for some groceries, but I would want at least a rear rack installed for when i do need to carry something, would i be better off with a rigid frame?

4. I really like the idea of having a single speed bike because of the low maintenance, does a rear hub add more wear to my drivetrain as a mid-drive would, especially on a single speed?

5. I wonder if i could take a stock wheel included with a new bike and relace that one with a hub motor..would look super clean!

6. Does using a carbon belt drive limit my options in terms of motors? (mid drive/front-hub/rear-hub)

7. I am really lost in terms of motor options, but I guess that will become easier to figure out once I have decided on the donor?

IDEAS:

1. I have that extra battery laying around, if that could be salvaged, I could use it as a range extender and put it on the rear rack for longer trips, not looking for more power, just more range. I want this to be an optional plug and play option and i wouldn't mind having to mount a rack on the rear rack for this on the occasional longer ride.

a. Is this possible?

b. can both batteries power the same motor?

c. If possible, how hard is putting together a set up like?

GRIN SIMULATOR HELP:

A few questions here

1. Does the controller make a huge difference in range and power so long as the amp rating is higher than the max output of my system?

2. Whats the difference between phaserunner hot and phaserunner cold?

3. In terms of throttle % is there a standard amount I should be using, should I compare all motors with 100% throttle, auto throttle, etc.?

4. There are SO many motor options, it is really intimidating, I know this request gets thrown around a lot, but any suggestions would be greatly appreciated.

a. I will (probably) be using either a fat bike or more likely a hardtail mountain bike for this build, I would like decent acceleration off of the line, but I wouldn't mind having to pedal a bit to achieve that.

b. More often than not I will be using this bike on busy NYC streets with lots of stop and go, is there a certain motor that works best for this? I have read that geared motors would be best, but I am also curious how that would compare to a direct drive motor if I were to pedal start from 0 rather than not in terms of getting the most range.

c. This motor will not be installed on the front end, it will be either rear drive or mid-drive

d. 20 mph feels fast for me, so there is technically no need to have the ability to go above that, but would be nice to have power to tap into like I have mentioned previously

p.s.

Although I have pretty much scrapped the Street King at this point, I feel like we should continue to trouble shoot the fork issues in order to better serve the community and future new builders. I am more than happy to further discuss what went wrong with the fork here!