Hello all, I have been plodding away with a conversion project for an old Lambretta for a while. As was expected the challenge has been packaging everything within the space available. I have a battery layout i would like to put up here for any thoughts and feedback.

The preferred specification I have for the pack is 72Volts with a capacity of 60Ah, I would also like to achieve a high enough output current to be able to run the pack well within its limits to prevent overheating and to maintain healthy cell chemistry.

To achieve this, due to space constraints I will need to split the pack into 2.

The options for this as I understand are:

1- connect the 2 packs as 2 stes of 10S x 12P packs - this would require a connection cable capable of handling the current running in series between the 2 packs and also balance cable connections to be made to a central BMS. - This strikes me as possibly a complicated set up to achieve.

2 - have 2 separate 20S x 6P packs with their own BMS with a switch to change packs. - It will leave me a little under rated on output, meaning that under load the cells will be pushed harder than I would like.

3 - connect the 2 packs in parallel each pack to have its own BMS. this is my preferred option as it will give me the best capacity and output, but obviously comes with some challenges.

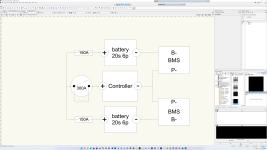

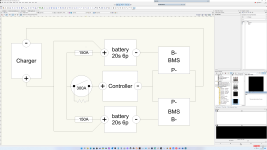

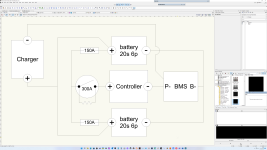

I have a schematic of how I would like to construct option 3, which I have attached.

The first schematic shows the system as it would be in operation the controller is an ASI BAC 8000, I have added a battery disconnect switch with a precharge circuit as well as 150A fuses per pack.

The second schematic shows a possible parallel charging circuit.

Thanks in advance for any thoughts.

The preferred specification I have for the pack is 72Volts with a capacity of 60Ah, I would also like to achieve a high enough output current to be able to run the pack well within its limits to prevent overheating and to maintain healthy cell chemistry.

To achieve this, due to space constraints I will need to split the pack into 2.

The options for this as I understand are:

1- connect the 2 packs as 2 stes of 10S x 12P packs - this would require a connection cable capable of handling the current running in series between the 2 packs and also balance cable connections to be made to a central BMS. - This strikes me as possibly a complicated set up to achieve.

2 - have 2 separate 20S x 6P packs with their own BMS with a switch to change packs. - It will leave me a little under rated on output, meaning that under load the cells will be pushed harder than I would like.

3 - connect the 2 packs in parallel each pack to have its own BMS. this is my preferred option as it will give me the best capacity and output, but obviously comes with some challenges.

I have a schematic of how I would like to construct option 3, which I have attached.

The first schematic shows the system as it would be in operation the controller is an ASI BAC 8000, I have added a battery disconnect switch with a precharge circuit as well as 150A fuses per pack.

The second schematic shows a possible parallel charging circuit.

Thanks in advance for any thoughts.