You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Revolt Rv-120 -- Sine wave-- Specialized big hit

- Thread starter Emoto

- Start date

panurge

10 kW

Hello Livetek

Note that The Revolts are actually outrunners and your 120-90 is a faster motor, useless for a direct drive we are talking about, but good for a 2 stage transmission.

Note that The Revolts are actually outrunners and your 120-90 is a faster motor, useless for a direct drive we are talking about, but good for a 2 stage transmission.

Oh sorry, i wasn't thinking the Revolts motor are Outrunners, that's great ! But i can't find picture of the motor mount..

And yes, i will do a 2 stage transmission in the swingarm if it's possible. But the question is: Can i have different speed and a large chain (like Bmx) ?

Thanks

And yes, i will do a 2 stage transmission in the swingarm if it's possible. But the question is: Can i have different speed and a large chain (like Bmx) ?

Thanks

livetek what makes the revolt at a kv of 43 so good is you only need a single reduction,= simpler/ lighter .....livetek said:Oh sorry, i wasn't thinking the Revolts motor are Outrunners, that's great ! But i can't find picture of the motor mount..

And yes, i will do a 2 stage transmission in the swingarm if it's possible. But the question is: Can i have different speed and a large chain (like Bmx) ?

Thanks

Lots of info here on mounts ect http://www.revolt.org.il/products/motors/

Attachments

Wheazel

10 kW

Really like this build, and have gotten my hands on a revolt 120 pro by now.

Have had good experiences with a standard rv100 since last year.

Do you support the rv120 on the axle sticking out the back side?

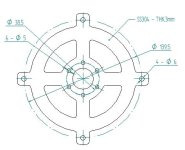

I think the mountingpattern looks so small and fragile, especially when mounting the motor as unsprung weight.

On my rv100 i did this with a bearing for the backside axle and a U-shaped motormount.

Whats are your thoughts on this?

My plan is to build a light and aerodynamic low powered motorcycle with the rv120.

Long term project for sure.

Have had good experiences with a standard rv100 since last year.

Do you support the rv120 on the axle sticking out the back side?

I think the mountingpattern looks so small and fragile, especially when mounting the motor as unsprung weight.

On my rv100 i did this with a bearing for the backside axle and a U-shaped motormount.

Whats are your thoughts on this?

My plan is to build a light and aerodynamic low powered motorcycle with the rv120.

Long term project for sure.

Wheazel good to hear, can you share your performance details with the rv 100 , what type of bike/riding conditions ect... as for a downhill frame type build i cant but think a rv100 might be all one would need, as a rv120 on the same frame might be a beast 8) .

Mounting - Good question! short answer, 2 mounts are better than one - of course, especially if riding off road and mounting on swingarm = more vibrations, but generally from what ive seen many have got away with the standard single mounting, method, but no 2 people ride the same, an indicator might be short term bearing life closest to mount.

On a motorcycle id be tempted to use 2 mounts.

Mounting - Good question! short answer, 2 mounts are better than one - of course, especially if riding off road and mounting on swingarm = more vibrations, but generally from what ive seen many have got away with the standard single mounting, method, but no 2 people ride the same, an indicator might be short term bearing life closest to mount.

On a motorcycle id be tempted to use 2 mounts.

ridethelightning

1 MW

- Joined

- Jul 21, 2013

- Messages

- 2,010

subscribed

Wheazel

10 kW

Emoto said:Wheazel good to hear, can you share your performance details with the rv 100 , what type of bike/riding conditions ect... as for a downhill frame type build i cant but think a rv100 might be all one would need, as a rv120 on the same frame might be a beast 8) .

Mounting - Good question! short answer, 2 mounts are better than one - of course, especially if riding off road and mounting on swingarm = more vibrations, but generally from what ive seen many have got away with the standard single mounting, method, but no 2 people ride the same, an indicator might be short term bearing life closest to mount.

On a motorcycle id be tempted to use 2 mounts.

I dont have much useful data on the rv100 as it has been babied all the time.

I went with a gocart centrifugal clutch and replaced the spring to a spring so soft its basically only holds the weights in the cluth from the gravity.

As soon as the clutch starts to rotate, it starts to grip. Problem is it doesnt grip very hard. It is designed for higher rpms. If a hill is steep enough, i cant ride with just the motor.

Later I have figured this mod was totally unnecessary for the rv100 with my current reduction, so ill prolly remove it this summer to make it direct drive.

(I have used the clutch-method with good success for smaller rc outrunners when startup torque is a bigger issue)

This aside, the bike works very well as long as driven between over 25km/h and 45km/h which is maybe 80% of the time.

Also have the CA limited to 30A on a 12s system, so its only 1250-1450W depending on chargestate. Have ridden around 1000km with the rv100.

All I can say is that I have gotten the motor to be maybe 50-60C on the outer case (hard to measure stator with the closed version) when running it with no current limit briefly last summer.

It was a warm day close to 30C and the power it saw was around 3-4kw shortterm and 2kw for a few mins testing the bike out.

macribs

10 MW

- Joined

- Jul 22, 2014

- Messages

- 3,702

@Wheazel

Hm. That clutch is it like variator type? Kind of like scooters have? With one primary and one secondary clutch? Or just single clutch?

If you use primary/secondary you can play around with various gearings to suit you need. I would think you should really use a stronger/firmer spring. That way it allows the motor to spin up in RPM before engaging.

That will give more rapid acceleration and more pull in steep hills. And it will keep the motor working in its most desired RPM range.

Would you mind posting a pic of you setup, or a link to the clutch?

Hm. That clutch is it like variator type? Kind of like scooters have? With one primary and one secondary clutch? Or just single clutch?

If you use primary/secondary you can play around with various gearings to suit you need. I would think you should really use a stronger/firmer spring. That way it allows the motor to spin up in RPM before engaging.

That will give more rapid acceleration and more pull in steep hills. And it will keep the motor working in its most desired RPM range.

Would you mind posting a pic of you setup, or a link to the clutch?

macribs said:Would you mind posting a pic of you setup, or a link to the clutch?

+1...would love to see some detail pics before I order my pro version

panurge said:Hello Livetek

Note that The Revolts are actually outrunners and your 120-90 is a faster motor, useless for a direct drive we are talking about, but good for a 2 stage transmission.

Those 120-90 hobbyking style motors suck (or at least they used to). Really high no load losses. Search here. The smaller 80mm hobbyking outrunners are better for some reason (thinner lams, smaller bearings, thicker magnet backing, etc)

In any case find the right motor for the job. A reduction is not the way to go even if it looks cool. It seems like you are saving weight with a smaller motor and higher rpm and more reduction but if you add the weight of the second stage back into a larger motor you get the same overall torque with with much more motor mass which means way more continous power handling

panurge

10 kW

I Agree about the HK motor at least that's what it seems by other user's experience, since I've used an 80-100 only... about the statement on single stage VS 2 stage, although could be right on words, it is often not supported by real facts. I have an astro 3220....with 2 stage. Please point me to a central motor slow enough and powerful enough (>4,5kw continuous aand 7-8kw proven peaks), in <4 kg of mass to be a single stage substitutor for my Astro (actually 1,9kg motor, 4,5 complete trans including chain and sprocket)flathill said:panurge said:Hello Livetek

Note that The Revolts are actually outrunners and your 120-90 is a faster motor, useless for a direct drive we are talking about, but good for a 2 stage transmission.

Those 120-90 hobbyking style motors suck (or at least they used to). Really high no load losses. Search here. The smaller 80mm hobbyking outrunners are better for some reason (thinner lams, smaller bearings, thicker magnet backing, etc)

In any case find the right motor for the job. A reduction is not the way to go even if it looks cool. It seems like you are saving weight with a smaller motor and higher rpm and more reduction but if you add the weight of the second stage back into a larger motor you get the same overall torque with with much more motor mass which means way more continous power handling

Wheazel

10 kW

Promised macribs to post some pics of the setup.

Some notes about this:

The technique works very well for making the life easier on the motor and controller.

Especially for smaller sensorless motors. Those are also better suited for this as they have planty of rpm to make a good engagement in the clutch.

The reason I went for this setup is because I was unsure about how rigid the controller is (noname controller i bought from revolt together with the motor) and how hard it would be on the system with a DD revolt100.

Turns out tho that this particular layout would have needed a slightly higher rpm motor or heavier weights in the clutch, to be optimal for this particular quite heavy bike.

Eventho it isnt perfect, its defenitely good enpugh for the majority of riding and most often the system is in 1:1 mode "locked in". Anywhere above 25km/h the clutch wont slip, only motor rpm varies depending on load. I have a current limit of 30A in the CA. This winter the bike has travelled roughly 1000km in all sorts of nasty snowy and icy conditions.

In hindsight I will probably try this motor as unsensored DD this summer by just removing the clutch, but on my other RC outrunner(150kV) bike, the clutch is perfect and stays.

That clutch is smaller and of this type tho:

Some notes about this:

The technique works very well for making the life easier on the motor and controller.

Especially for smaller sensorless motors. Those are also better suited for this as they have planty of rpm to make a good engagement in the clutch.

The reason I went for this setup is because I was unsure about how rigid the controller is (noname controller i bought from revolt together with the motor) and how hard it would be on the system with a DD revolt100.

Turns out tho that this particular layout would have needed a slightly higher rpm motor or heavier weights in the clutch, to be optimal for this particular quite heavy bike.

Eventho it isnt perfect, its defenitely good enpugh for the majority of riding and most often the system is in 1:1 mode "locked in". Anywhere above 25km/h the clutch wont slip, only motor rpm varies depending on load. I have a current limit of 30A in the CA. This winter the bike has travelled roughly 1000km in all sorts of nasty snowy and icy conditions.

In hindsight I will probably try this motor as unsensored DD this summer by just removing the clutch, but on my other RC outrunner(150kV) bike, the clutch is perfect and stays.

That clutch is smaller and of this type tho:

recumpence

1 GW

if you remove the spring weights, the clutch response will be far better. Your controller will survive just fine assuming the clutch does not lock near zero rpm. However, clutch engagement at a very low RPM is best for an electric system.

recumpence

1 GW

Absolutely not true.flathill said:panurge said:Hello Livetek

Note that The Revolts are actually outrunners and your 120-90 is a faster motor, useless for a direct drive we are talking about, but good for a 2 stage transmission.

A reduction is not the way to go even if it looks cool. It seems like you are saving weight with a smaller motor and higher rpm and more reduction but if you add the weight of the second stage back into a larger motor you get the same overall torque with with much more motor mass which means way more continous power handling

Wheazel

10 kW

recumpence said:if you remove the spring weights, the clutch response will be far better. Your controller will survive just fine assuming the clutch does not lock near zero rpm. However, clutch engagement at a very low RPM is best for an electric system.

My both systems use springs so weak they basically only hold the gravity of the weights.

Engagement starts at near zero rpm, which works wonders as you said.

recumpence said:Absolutely not true.flathill said:panurge said:Hello Livetek

Note that The Revolts are actually outrunners and your 120-90 is a faster motor, useless for a direct drive we are talking about, but good for a 2 stage transmission.

A reduction is not the way to go even if it looks cool. It seems like you are saving weight with a smaller motor and higher rpm and more reduction but if you add the weight of the second stage back into a larger motor you get the same overall torque with with much more motor mass which means way more continous power handling

Compare the 2013 Zero MX and the 2015 Alta Redshift.The Zero has .7kw more capacity and weighs 15 pounds more.

The Zero uses a single stage reduction and the motor makes 68 ft pounds of torque and is air cooled. The 75-7 motor actually capable of much more than 54hp even air cooled. If liquid cooled, it would be a monster.

The Alta uses a two stage reduction and the motor only makes 30 ft pounds of torque and is liquid cooled. The Alta can only put out 40hp for 10 seconds even with a complicated and highly optimized liquid cooling system likely because to motor is so tiny relative to the zero motor. It can only do 25hp continuous. It also has a nasty gear whine and more drivetrain losses than a 1 stage reduction. The smaller motor is probably cheaper to make though, if you don't include the cooling system.

Now the Alta might be all all around better bike than the MX simply because the frame and component set, but the Zero drive train is superior it seems

recumpence

1 GW

Wow, I am so tired of this crap being thrown around. You need to compare apples with apples.

Assuming identical efficiency motors, high power with low RPM requires far more copper fill weight than the weight of a well designed reduction unit with a smaller high RPM motor.

Also, gear whine is the reason belt drive is beneficial.

Assuming identical efficiency motors, high power with low RPM requires far more copper fill weight than the weight of a well designed reduction unit with a smaller high RPM motor.

Also, gear whine is the reason belt drive is beneficial.

recumpence said:Wow, I am so tired of this crap being thrown around. You need to compare apples with apples.

Assuming identical efficiency motors, high power with low RPM requires far more copper fill weight than the weight of a well designed reduction unit with a smaller high RPM motor.

Also, gear whine is the reason belt drive is beneficial.

Assuming identical efficiency both motors will produce the same waste heat and both systems did produce the same peak power, the larger motor will be able to produce the near the peak power for longer (thermal mass and surface area). One less stage of reduction also means higher overall system efficiency. You could build the smaller motor with one stage of reduction if you had the space, but it would still have a higher reduction ratio, and the smaller motor would still have less active motor weight (copper, etc). Whether both motors have liquid cooling, or both are air cooled, the same limitations apply.

It all comes down to sizing the motor for the application, it seems

recumpence

1 GW

flathill said:recumpence said:Wow, I am so tired of this crap being thrown around. You need to compare apples with apples.

Assuming identical efficiency motors, high power with low RPM requires far more copper fill weight than the weight of a well designed reduction unit with a smaller high RPM motor.

Also, gear whine is the reason belt drive is beneficial.

Assuming identical efficiency both motors will produce the same waste heat and both systems did produce the same peak power, the larger motor will be able to produce the near the peak power for longer (thermal mass and surface area). One less stage of reduction also means higher overall system efficiency. You could build the smaller motor with one stage of reduction if you had the space, but it would still have a higher reduction ratio, and the smaller motor would still have less active motor weight (copper, etc). Whether both motors have liquid cooling, or both are air cooled, the same limitations apply.

It all comes down to sizing the motor for the application, it seems

Ok, you go ahead and run an oversize motor and those of us who don't know what we are doing will continue enjoying our high performance light weight systems.

panurge

10 kW

There are pro and contra in both the approaches...and there are fields in which the single-stage-bigger-motor way should result, as for many aspectscin theory seems, the best one. But there are fields in which for many reasons, actuaĺly, you cannot equal the mass/power ratio of a 2 stage trans with a fast motor and/or the way that ratio is usable on a LEV, or, better, a bicycle.

Again please point me to a motor in the 3-9Kw range that works on a single stage trans at a reasonalble tension / current with a power factor similar to a 2 staged fast motor (astros ecc.). We are speaking of motor plus a complete trans till the wheel and any cooling system...

What I cant understand is why someone attempts to universalize his personal experience and point of view, or even a particular proven scientific statement but based on a single variable, and apply it to everything, and try to persuade everybody.

Again please point me to a motor in the 3-9Kw range that works on a single stage trans at a reasonalble tension / current with a power factor similar to a 2 staged fast motor (astros ecc.). We are speaking of motor plus a complete trans till the wheel and any cooling system...

What I cant understand is why someone attempts to universalize his personal experience and point of view, or even a particular proven scientific statement but based on a single variable, and apply it to everything, and try to persuade everybody.

Thud

1 MW

panurge said:There are pro and contra in both the approaches...and there are fields in which the single-stage-bigger-motor way should result, as for many aspectscin theory seems, the best one. But there are fields in which for many reasons, actuaĺly, you cannot equal the mass/power ratio of a 2 stage trans with a fast motor and/or the way that ratio is usable on a LEV, or, better, a bicycle.

Again please point me to a motor in the 3-9Kw range that works on a single stage trans at a reasonalble tension / current with a power factor similar to a 2 staged fast motor (astros ecc.). We are speaking of motor plus a complete trans till the wheel and any cooling system...

What I cant understand is why someone attempts to universalize his personal experience and point of view, or even a particular proven scientific statement but based on a single variable, and apply it to everything, and try to persuade everybody.

Maybe the Joby JM1S? What are you looking for exactly?

Astro's are awesome little motors. Very high quality and smco magnets

http://www.jobymotors.com/public/views/pages/products.php

speedmd

10 MW

I am in the same boat, not being able to buy a mid size (6 -10 kw) light weight motor that comes close to the performance of the 3220 setup short of adapting a Joby or Plettenberg with a host of control issues to work out. It is a expensive risk to take. Golden is much larger/ heavier and detuned in comparison. The Zero motor looks amazing, but quoted 10K for motor, controller and wiring. Anyone know where to find one more reasonably.

panurge

10 kW

flathill said:panurge said:There are pro and contra in both the approaches...and there are fields in which the single-stage-bigger-motor way should result, as for many aspectscin theory seems, the best one. But there are fields in which for many reasons, actuaĺly, you cannot equal the mass/power ratio of a 2 stage trans with a fast motor and/or the way that ratio is usable on a LEV, or, better, a bicycle.

Again please point me to a motor in the 3-9Kw range that works on a single stage trans at a reasonalble tension / current with a power factor similar to a 2 staged fast motor (astros ecc.). We are speaking of motor plus a complete trans till the wheel and any cooling system...

What I cant understand is why someone attempts to universalize his personal experience and point of view, or even a particular proven scientific statement but based on a single variable, and apply it to everything, and try to persuade everybody.

Maybe the Joby JM1S? What are you looking for exactly?

Astro's are awesome little motors. Very high quality and smco magnets

http://www.jobymotors.com/public/views/pages/products.php

AGAIN (3rd time): Looking for a motor in the sub10Kw range that could be used as DIRECT DRIVE with a power factor similar to my actual Astro 2 stage system, an useful form factor, and using a transmission suitable for a bicycle. Mostly , It should be available, controllable and proven.

Although the joby could be better than an Astro in bench tests, it is not useful for many reasons for my needs (price, form fator, control ecc.) and anyway not so easy to be used with a single stage. I'm pretty happy with my little astro on 2 stage for my bicycle.