Absolutely awesome project Mr Alex. My highest appreciation of your stunningly beautiful mechanical artwork. I am in awe of your most skillful craftsmanship and vast knowledge of electronics and mechanics. I fell in love with electric scooters and was really hooked when I got my Dualtron 2, which is dual motors. It has really fun weight to power ratio and I ride it everywhere. I Love it! I almost bought the new Dualtron X 2, but decided to build my own scooter too. I am trying to push the wheel size larger while still keeping a low scooter deck. My new scooter has dual motors and is looking pretty wild also. I would jump at any chance to talk scooters with you anytime sir. I am building a few EV projects and am having so much fun learning more. Hoping all is good there. If you ever come to visit sunny San Jose, California you will have a place to stay and a buddy to go riding with! I really appreciate you sharing everything here so well for many of us to learn and be amazed brother.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

24kW stand-up scooter with air suspension

- Thread starter alex_2d

- Start date

Silenthunter

1 kW

- Joined

- Mar 24, 2013

- Messages

- 316

Updates on the project:

https://www.youtube.com/watch?v=c72BC6YpGWY

https://www.youtube.com/watch?v=vAMzjBMBlk8&t=17s

https://www.youtube.com/watch?v=sXdc7ukgijE

https://www.youtube.com/watch?v=wNOqBZvezgU

https://www.youtube.com/watch?v=c72BC6YpGWY

https://www.youtube.com/watch?v=vAMzjBMBlk8&t=17s

https://www.youtube.com/watch?v=sXdc7ukgijE

https://www.youtube.com/watch?v=wNOqBZvezgU

Silenthunter

1 kW

- Joined

- Mar 24, 2013

- Messages

- 316

Updates:

https://www.youtube.com/watch?v=vAMzjBMBlk8

https://www.youtube.com/watch?v=vAMzjBMBlk8

Attachments

Hi Alex,

Bravo...!!!!!!

I read all your posts. What you had done is a Magic.

Actually In my country(India) we don't have DIY bikes. And I am planning to build one.

Eventhough I have read all the posts, It would be very helpful if you share the following information of the motor.

Rear Tyre size

Hub motor radius

Stator length

Magnet size

Number of turns in windings

Battery info(V & Amph)

How you implemented cooling system into the hub motor.

So that I will also try to build one. I am a software engineer by profession so not sure whether I will get the same perfection like you. But definitely will give a try.

Your MIND & HANDS are very gifted.

Happy for you.

Cheers,

Rajesh Kumar G

Well, let's continue the topic)

Many thanks to all readers of this topic, your attention and such high marks of my work!

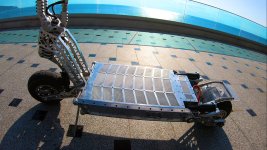

The project to create a scooter "Vostok 1 ver.2.0" turned out to be much more difficult to implement than I expected at the beginning... Therefore, everything dragged on for a much longer time... Nevertheless, the prototype of the new scooter is almost ready! It remains to finish some elements. But it is already possible to run-in and test to obtain real TTX.

Here are some photos of what happened and the first videos from the tests.

[youtube]dm6FrH5O1jc[/youtube]

[youtube]xUJdXevDOcM[/youtube]

[youtube]i7CldNqmRfM[/youtube]

[youtube]6SO9_kXW8xk[/youtube]

Please forgive me for writing little and rarely in this topic. In the near future, I will try to describe in detail the process of creating this scooter

Many thanks to all readers of this topic, your attention and such high marks of my work!

The project to create a scooter "Vostok 1 ver.2.0" turned out to be much more difficult to implement than I expected at the beginning... Therefore, everything dragged on for a much longer time... Nevertheless, the prototype of the new scooter is almost ready! It remains to finish some elements. But it is already possible to run-in and test to obtain real TTX.

Here are some photos of what happened and the first videos from the tests.

[youtube]dm6FrH5O1jc[/youtube]

[youtube]xUJdXevDOcM[/youtube]

[youtube]i7CldNqmRfM[/youtube]

[youtube]6SO9_kXW8xk[/youtube]

Please forgive me for writing little and rarely in this topic. In the near future, I will try to describe in detail the process of creating this scooter

It all started with the engine. Based on the experience gained in the East 1, I have developed my engine, which is ideal for a go-kart tire. The challenge was to squeeze as much energy into this size as possible. To achieve this goal, I used the highest quality components. I ordered magnets and a stator from different companies, everything else was done by myself.

It turned out to be very difficult to put very powerful magnets in a steel cylinder. At the first attempts, there were a lot of pinched fingers and broken magnets

With the stator, everything was much easier

Next, the side covers of the engine made of aviation aluminum D16T

Steel axle, with an outlet for wires and channels for coolant.

Then, the main elements of the rear suspension are made of the same aluminum

Double dropouts made of steel

Here is a small set for the first tests

Checking the tightness of the tire

The first tests of the engine. To be honest, I was very nervous when I connected everything, I was afraid that it would not spin at all or burst into flames))

[youtube]t_Gg7Wc40Tg[/youtube]

Just the wheel is spinning )

[youtube]Gy0dEiOxrEo[/youtube]

It turned out to be very difficult to put very powerful magnets in a steel cylinder. At the first attempts, there were a lot of pinched fingers and broken magnets

With the stator, everything was much easier

Next, the side covers of the engine made of aviation aluminum D16T

Steel axle, with an outlet for wires and channels for coolant.

Then, the main elements of the rear suspension are made of the same aluminum

Double dropouts made of steel

Here is a small set for the first tests

Checking the tightness of the tire

The first tests of the engine. To be honest, I was very nervous when I connected everything, I was afraid that it would not spin at all or burst into flames))

[youtube]t_Gg7Wc40Tg[/youtube]

Just the wheel is spinning )

[youtube]Gy0dEiOxrEo[/youtube]

An embodiment of principle 'Who needs aero when you can just add power'

A CNC porn, too. I wish it was not wasted on a 'stand up scooter', but is cool, I give you that.

I wonder if you can fit a sort of half-body fairing on this thing, and aero bars to hide behind it for 100+ kmh at a small fraction of power? Makes a ton of sense if you ask me...

A CNC porn, too. I wish it was not wasted on a 'stand up scooter', but is cool, I give you that.

I wonder if you can fit a sort of half-body fairing on this thing, and aero bars to hide behind it for 100+ kmh at a small fraction of power? Makes a ton of sense if you ask me...

The deck is also made of aluminum

Front and rear deck

Side parts

Viewing window for coolant in the side of the deck

Compartment for the cooling system pump

Kit for initial assembly

Coolant channels inside the deck walls

Fitting

Additional processing for the fit of the upper and lower cover of the deck

Production of the upper and lower deck covers

Front and rear deck

Side parts

Viewing window for coolant in the side of the deck

Compartment for the cooling system pump

Kit for initial assembly

Coolant channels inside the deck walls

Fitting

Additional processing for the fit of the upper and lower cover of the deck

Production of the upper and lower deck covers

SlowCo

1 MW

WOW!

8)

Hi Alex,

Awesome @@

Could you please let us know how you are pumping in & out the coolant into the motor. I know that it is going via the axle but after that what happens I dont know.

A diagram will be helpfull.

Also how you connected all the inner side decks for coolant circulation.?

The information you give is much informative and will be helpful in designing my bike and fixing overheating issues in the beforehand itself.

Thanks & Regards,

Rajesh

Awesome @@

Could you please let us know how you are pumping in & out the coolant into the motor. I know that it is going via the axle but after that what happens I dont know.

A diagram will be helpfull.

Also how you connected all the inner side decks for coolant circulation.?

The information you give is much informative and will be helpful in designing my bike and fixing overheating issues in the beforehand itself.

Thanks & Regards,

Rajesh

Chalo

100 TW

Hi All,

Since Alex is a busy bee,

Could anybody help me with the answers for the below questions?

1. How the oil is pumped into the motor. Are there any compartments installed for oil circulation/heat exchangers inside the motor.? If so then a block diagram will be very helpfull.

2. How is the folding system designed.?

3. I don't see a charging port. I see one small port kind of thing at the rear, next to cooling compartment. Is that a charging port.?

4. What is the dimensions of stator, magnet & cylinder.?

5. Is the motor waterproof.? If so what are the waterproofing method, process and materials that I need to use.

Too much to ask..Being from software background I don't know the above. Hence asking.

If I get the above details, then I will start designing as per my requirement.

Expecting a valuable reply.

Cheers,

Rajesh

Since Alex is a busy bee,

Could anybody help me with the answers for the below questions?

1. How the oil is pumped into the motor. Are there any compartments installed for oil circulation/heat exchangers inside the motor.? If so then a block diagram will be very helpfull.

2. How is the folding system designed.?

3. I don't see a charging port. I see one small port kind of thing at the rear, next to cooling compartment. Is that a charging port.?

4. What is the dimensions of stator, magnet & cylinder.?

5. Is the motor waterproof.? If so what are the waterproofing method, process and materials that I need to use.

Too much to ask..Being from software background I don't know the above. Hence asking.

If I get the above details, then I will start designing as per my requirement.

Expecting a valuable reply.

Cheers,

Rajesh

Chalo

100 TW

RaicceKG said:Could anybody help me with the answers for the below questions?

Hi Rajesh. I have a related question for you.

How many of the electric motors you see on a day to day basis use liquid cooling?

Oh, one more question:

Why do you think that is?

markz

100 TW

I've been thinking about making a stand up scooter myself.

I don't think I'd go with high powered rc motors and small wheels.

I love riding through tree's, over ruts, on single track so a hub motor would work.

16" tire mounted onto hub flange (no spokes), would weigh a lot if carrying into a mall but I guess you could weld on some securing points for a Kryptonite Yellow Forgetaboutit NYC U-lock or two.

Backpack battery would be my route as I use battery for ebike to.

How to secure hub motor without welding 1/2" plate steel for non easily removable hub motor

Winters coming so its not something I think about a lot. I only think about when I see private stand up scooters whiz by which irritate me so I know how walkers feel about ebikes :lol: :lol: :lol:

----

Oil leaks and makes a mess

Sealing surfaces between cover plate (hubs) isnt a crucial concern for hub motor makers

Just use Statorade (Ferrofluid) if you want something that wont leak

Lastly, 10kw stand up scooter is absolute craziness unless you want it for going up ski resort "ski-outs" which are long mile(s) runs with some very steep sections. 30 or 40 mph on one = crazy

One pothole, one curb without jumping and it is more then just Chalo's second pic/gif

https://endless-sphere.com/forums/viewtopic.php?p=1680057#p1680057

I don't think I'd go with high powered rc motors and small wheels.

I love riding through tree's, over ruts, on single track so a hub motor would work.

16" tire mounted onto hub flange (no spokes), would weigh a lot if carrying into a mall but I guess you could weld on some securing points for a Kryptonite Yellow Forgetaboutit NYC U-lock or two.

Backpack battery would be my route as I use battery for ebike to.

How to secure hub motor without welding 1/2" plate steel for non easily removable hub motor

Winters coming so its not something I think about a lot. I only think about when I see private stand up scooters whiz by which irritate me so I know how walkers feel about ebikes :lol: :lol: :lol:

----

Oil leaks and makes a mess

Sealing surfaces between cover plate (hubs) isnt a crucial concern for hub motor makers

Just use Statorade (Ferrofluid) if you want something that wont leak

Lastly, 10kw stand up scooter is absolute craziness unless you want it for going up ski resort "ski-outs" which are long mile(s) runs with some very steep sections. 30 or 40 mph on one = crazy

One pothole, one curb without jumping and it is more then just Chalo's second pic/gif

https://endless-sphere.com/forums/viewtopic.php?p=1680057#p1680057

Chalo said:

Hi!RaicceKG said:Could anybody help me with the answers for the below questions?

Please forgive me, but I would not like to make public all the nuances of production.

I'm also wondering why?Chalo said:Oh, one more question:

Why do you think that is?

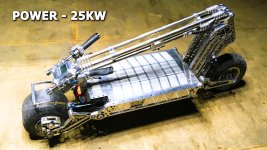

In the new version of the scooter , the power is 25 kW in one rear wheel )markz said:Lastly, 10kw stand up scooter is absolute craziness unless you want it for going up ski resort "ski-outs" which are long mile(s) runs with some very steep sections. 30 or 40 mph on one = crazy

One pothole, one curb without jumping and it is more then just Chalo's second pic/gif

Everything depends very much on the design of the vehicle. On this scooter, the speed of 50 Mph feels very comfortable.

You have to be blind not to notice the curb))) And so, the suspension with a stroke of 160mm, allows you to move freely off-road, even on such small wheels

Now a little bit about the rear suspension. In this version, the rear suspension is multi-link. So, I haven't come up with another way to position the shock absorbers horizontally and get a positive progression.

Also in this version of the scooter, I changed the way the titanium axes are fixed. I had to invent my own screws

This is how the titanium axis of the rear pendulum looks like

A set of bushings for the rear suspension made of graphite-filled polyamide-6

Rear suspension assembly

The first test of the engine in the assembled suspension

Working stroke of the rear suspension 160mm

[youtube]8Ogi8m7e5Ak[/youtube]

Also in this version of the scooter, I changed the way the titanium axes are fixed. I had to invent my own screws

This is how the titanium axis of the rear pendulum looks like

A set of bushings for the rear suspension made of graphite-filled polyamide-6

Rear suspension assembly

The first test of the engine in the assembled suspension

Working stroke of the rear suspension 160mm

[youtube]8Ogi8m7e5Ak[/youtube]

The front suspension also has a working stroke of 160 mm. Unlike the first version of the scooter, the rake and trail have been changed

Reinforced steering cup

I also significantly strengthened the attachment point to the deck

Steel steering axle with hole for wiring and hydraulic line

The entire front suspension assembly

Reinforced steering cup

I also significantly strengthened the attachment point to the deck

Steel steering axle with hole for wiring and hydraulic line

The entire front suspension assembly

Similar threads

- Replies

- 8

- Views

- 4,516