Bummed out cell

Ok, to sum up some posts elsewhere, my pack died! The evidence is twofold:

One, My smart charger wont' go into charge mode - the red LED flashes at me, telling me its a no go; do some Voltsphreak single cell charging on the low cells & try again; lo' the smart charger starts, cycles through and completes a full charge! I'm thinking great, I'm good to go.

Two, I go, and at first all is OK, but the motor chugs out and I've got no juice. What the frellingfrack is that?

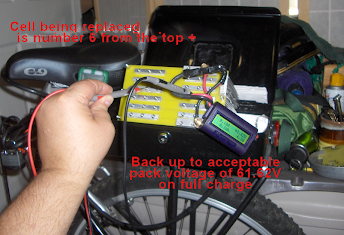

Bummer, yea, so out with the voltmeter to check out what cells are OK and which are not. Turns out there is just one bad guy, in position 6 on the pack (the middle).

Here's where the story turns out good. All my choices are proven in this scenario. Agnius' kit allows not only for easy construction, but also easy de-construction. Also, when I bought my cells from Victpower, I got 14, so 2 extra in my 12S pack. I was able to pull out just the one bad cell, without having to remove any others, and insert a replacement. Smooth as a wet pussy and feeling just as nice.

So, one more piece of information on that bad cell. It simply won't hold a charge. I can get it up to around 3V, but as soon as I remove charge current, it takes a dive, until its more or less fully discharged.

Poll - what happenned?

If you're into the A123 AMP20 pack line, I'd like your opinion on what went wrong.

- A. The cell was bad from the beginning, just a casualty of the salvage that put these half-tab cells on the market through Victpower.

- B. Without a BMS, and through usage, the cell became dangerously low and lost its ability to hold charge.

- C. With the accident (hit by car and knoked to the pavement), the jar in fact caused damage to the pack - fortunately just the one cell.

- D. With the bike in the shop for repair, and since I inadvertently left the controller on and Watts Up meter connected, the Watts Up drained the cell and killed it in the process.

- E. An alien being that lives on nanophosphate li-ion fluff invaded and sucked it dry.

- F. Something other

Top construction mate well done.

Top construction mate well done.