How will they measure you to build the frame, and the riding position you want if its not in person doing the measuring because they have special gadget you sit on and they measure it all hence custom frame, $540 wouldnt cover the cost of measuring and building the frame.

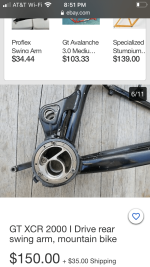

Buy a frame thats close to what you want, make it a steel/cromo bike so you can weld stuff to it.

What size bolt do you want the braze-ons to be? M5, M6?

The more the merrier if you're hauling weight, doesnt take much to snap the bolts, done it a few times on rear racks with batteries. See these seem so weak, but if you got enough of them should be strong.

https://framebuildersupply.com/collections/braze-ons

Maybe a grade 8 bolt with these https://www.mcmaster.com/grade-8-bolts/high-strength-steel-coupling-nuts-grade-8/ if you can mount them, weld them on. Your probably not looking at weight savings are you :lol:

You could just buy a welder on sale from Harbor Freight then sell it after your done, if you go with a steel/cromo frame.

I watched video's on which welder to buy, its easier to learn on a stick arc welder then it is a mig and tig is the hardest.

Or look at the online classifieds for a buzz box arc welder old school Lincoln one, just make sure all the cables are there and clamps.

Hummina Shadeeba said:

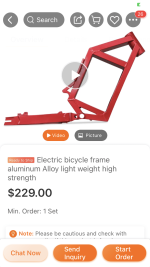

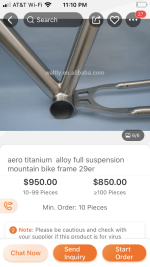

the custom frame is pretty cheap at 540$ shipped and I’ll get rid of all the braze-ons that would be in the way of the battery too.