Arvicola Terrestris said:

DAND214 said:

Very interesting repair.

Bad needle bearongs, have you checked the crank shaft for wear also?

Dan

God question there!

Yes, there are wear on the left side of the shaft, were the rusty needle bearing was, it's visible. But i don't know yet how much. I'm going to make a roughness test of the shaft surface to find the Ra value, and I will use the right side of the shaft as my reference surface.

/philip

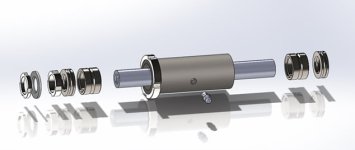

I have the result now, the wear on the left side of the shaft is more and less damaged then anticipated.

The diameter of the shaft is reduced with 6/1000 of a millimeter (right reference side: 16.988mm, Left damaged side: 16.982mm) So thats not a problem.

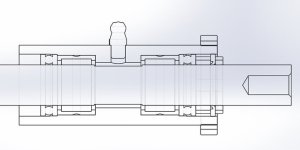

As the surface roughness goes:

Normally a surface that is rough, means high Ra value, will wear quickly and have higher friction.

I have checked the surface roughness, and it's not so bad theoretically.

The surface roughness on the right reference side is 0.42 μm Ra

The surface roughness on the left damaged side is 1.13 μm Ra

Then I have polished the damaged side and now I get these readings: 0.13 μm Ra and 0.62 μm Ra

(Ra is an average number for the hight of the peaks on the surface).

BUT the problem is that there are a few very deep groves on the surface and the rest is smooth. As seen on scan number four (below) there are areas that are smooth and then some areas that have high peaks, but the average is nice as seen above.

I haven't yet decided what to do, get a new shaft or rely on my greasing project will keep the bearings alive hence the deep grooves.

If I go ahead and keep the shaft, then I could check the state of the bearing in a few month and also see if my homemade seal works. The bearing has arrived at customs in Denmark, so I just need to get them. A new shaft will take several weeks to arrive.

/philip