"small bunches" of 400 or 500, maybe? :lol: They'd make great bike packs, for sure.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building cylindrical battery pack for Dummy!

- Thread starter leamcorp

- Start date

jonescg

100 MW

Hi All,

My fiancée is building an e-bike and were using A123 cylindrical cells (the 266550 ones). I was thinking of using PVC electrical or storm water conduit for loading the 4 paralleled cells, and however many I wanted in length for the cells in series. What would make a good connector between them? Light weight tinned copper strips with dimples where the cells make contact?

Whaddayareckon?

My fiancée is building an e-bike and were using A123 cylindrical cells (the 266550 ones). I was thinking of using PVC electrical or storm water conduit for loading the 4 paralleled cells, and however many I wanted in length for the cells in series. What would make a good connector between them? Light weight tinned copper strips with dimples where the cells make contact?

Whaddayareckon?

Attachments

jonescg

100 MW

We decided to go with a similar arrangement as the original poster, except it's going to be in a plastic enclosure. But the PVC pipe idea isn't too crazy an idea, I would have thought...

MitchJi

10 MW

HI Patrick,

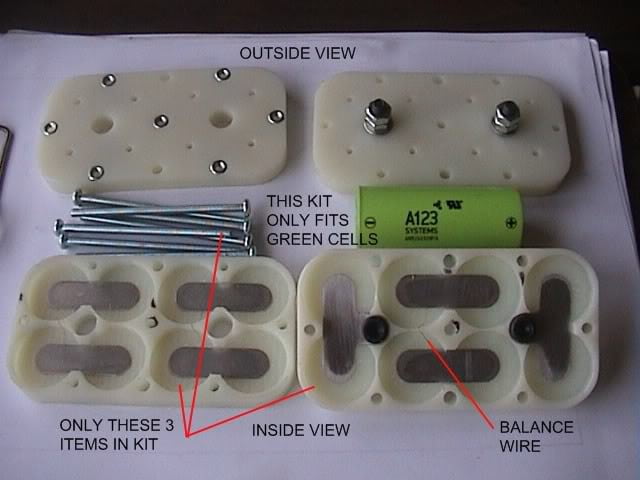

You could make "end caps" something like this (plastic or wood), without the round holes:

Ending up with something like a tray with vertical sides or a box lid, something like this lid:

You could then use thin sheets of brass or copper for the ends.

So far its might not be too much work. Mass produce 68 "end caps" the correct size and lay in 68 pieces of copper or brass sheet.

You would need to figure out a way to incorporate springs. You could probably have slots punched in the sheets for the clip springs or drill holes a little bit smaller than the bases of round springs. 70 holes or slots is quite a few but you could probably do at least 20-30 sheets at a time.

Maybe you could figure out a way clip the springs to the cell ends.

methods said:I have 950 of them in a "temporary" configuration in my car but now that I am looking at doing the full pack of ~2500 the prospects are looking dim.

5000+ spot welds ? no thanks

Big racks?

for 34S 70P I would have to build 34 individual 70P racks - or 17 2S 70P etc

All of that sounds big and heavy and lame

Tons of interconnects, lots of expensive materials, a real production.

-methods

You could make "end caps" something like this (plastic or wood), without the round holes:

Ending up with something like a tray with vertical sides or a box lid, something like this lid:

You could then use thin sheets of brass or copper for the ends.

So far its might not be too much work. Mass produce 68 "end caps" the correct size and lay in 68 pieces of copper or brass sheet.

You would need to figure out a way to incorporate springs. You could probably have slots punched in the sheets for the clip springs or drill holes a little bit smaller than the bases of round springs. 70 holes or slots is quite a few but you could probably do at least 20-30 sheets at a time.

Maybe you could figure out a way clip the springs to the cell ends.

PedalingBiped

100 W

you are talking 4p and then you want to put them in a tube to make connection with another 4p?

if your copper straps are stiff enough, then a dimple would work. for a tube arrangement, I think a sheet of copper, the same diameter as the tube, with dimples could work, you would have to provide compression some how'

if your copper straps are stiff enough, then a dimple would work. for a tube arrangement, I think a sheet of copper, the same diameter as the tube, with dimples could work, you would have to provide compression some how'

GGoodrum

1 MW

I agree, the 4p tube idea might work, but I'd worry a bit about the dimpled strips being able to make a solid connection unless the cells are installed "loose" and the compression is done in a way that each of the four "stacks" of cells can be compressed separately.

-- Gary

-- Gary

MitchJi

10 MW

Hi,

I'd be worried about using dimpled copper instead of springs. Maybe with individually tensioned columns adjusted very carefully.

I'd make slots for clip springs or drill holes sized for round springs.

I'd be worried about using dimpled copper instead of springs. Maybe with individually tensioned columns adjusted very carefully.

I'd make slots for clip springs or drill holes sized for round springs.

PedalingBiped

100 W

For a few batteries, the clips would be fool proof. For a bigger pack, I will be try to use the dimple method. I can't see the dimple flattening out. The batteries are not in compression enough to flatten them out.

The batteries already are trying to contact the next cell(Positive contact is a nub). We just need to make it easier for them.

The batteries already are trying to contact the next cell(Positive contact is a nub). We just need to make it easier for them.

EVDragRacer

1 kW

- Joined

- Dec 10, 2010

- Messages

- 318

We are using Headway Batteries, much easier to build.

EVDragRacer

1 kW

- Joined

- Dec 10, 2010

- Messages

- 318

EVDragRacer

1 kW

- Joined

- Dec 10, 2010

- Messages

- 318

Jeremy Harris

100 MW

EVDragRacer said:We are using Headway Batteries, much easier to build.

Yes, there are several threads here about screwing together Headways, but this thread is about putting packs together using cylindrical cells that aren't Headways, PSI or other cell with either threaded rod or threaded socket terminations.

The big advantage is that this makes for a simple way to make up A123 packs, which will massively out perform something like the Headways, with their relatively poor discharge C rate and high Ri. Normally, the only safe way to build A123 packs is to resistance weld tabs to the ends, like the old Headways. Some people have got away with soldering terminations to A123s, but it's not really ideal and tedious for building a big pack.

It'd be nice if we could get A123 cells with nice terminations, but we're pretty much stuck with plain end caps. Their performance is leagues ahead of other LiFePO4 cells though, so the effort of making mounting systems such as those in this thread is worthwhile.

Jeremy

EVDragRacer

1 kW

- Joined

- Dec 10, 2010

- Messages

- 318

EVDragRacer

1 kW

- Joined

- Dec 10, 2010

- Messages

- 318

I agree, if A123 Batteries had "screw type" terminal ends life would be much easier. We are satisfied with the Headway Battery for now.

Jeremy Harris said:EVDragRacer said:We are using Headway Batteries, much easier to build.

Yes, there are several threads here about screwing together Headways, but this thread is about putting packs together using cylindrical cells that aren't Headways, PSI or other cell with either threaded rod or threaded socket terminations.

The big advantage is that this makes for a simple way to make up A123 packs, which will massively out perform something like the Headways, with their relatively poor discharge C rate and high Ri. Normally, the only safe way to build A123 packs is to resistance weld tabs to the ends, like the old Headways. Some people have got away with soldering terminations to A123s, but it's not really ideal and tedious for building a big pack.

It'd be nice if we could get A123 cells with nice terminations, but we're pretty much stuck with plain end caps. Their performance is leagues ahead of other LiFePO4 cells though, so the effort of making mounting systems such as those in this thread is worthwhile.

Jeremy

EVDragRacer

1 kW

- Joined

- Dec 10, 2010

- Messages

- 318

Guys I have a very good question, can you build larger packs with the Enerland "Pre-built" packs and connect each "unit" in series to up the battery box AH and then connect each battery box in series to up the system voltage?

PedalingBiped

100 W

Tis a beatiful battery, but your in the wrong thread. this is for cylindrical batteries.

Try posting in the ebike general discussion. or ask a moderator in a PM to move it.

Try posting in the ebike general discussion. or ask a moderator in a PM to move it.

Hi Guys

Im a noob to the electric bicycle hobby and have just started building a batery pack for an a2b metro bike. I ran across this thread and liked the ideas presented here. If I can find some affordable cells imight try to make some of the cell holders like the nylon versions shown here. I have been reading through the various postings here on es for a long time now and have only barely scratched the surface of the information contained here, just amazing!

if anyone is interested you can see the battery pack im building here:

http://tinyurl.com/4mzz5jm

I will also be attempting to rebuild the internal battery pack with fresh cells once I finish the external pack. This will be much tougher as I will need to spot weld the cells together so I need to make the custom tabs to weld to the cells. http://tinyurl.com/4gxyvow

Regards

Bill Griffin

Im a noob to the electric bicycle hobby and have just started building a batery pack for an a2b metro bike. I ran across this thread and liked the ideas presented here. If I can find some affordable cells imight try to make some of the cell holders like the nylon versions shown here. I have been reading through the various postings here on es for a long time now and have only barely scratched the surface of the information contained here, just amazing!

if anyone is interested you can see the battery pack im building here:

http://tinyurl.com/4mzz5jm

I will also be attempting to rebuild the internal battery pack with fresh cells once I finish the external pack. This will be much tougher as I will need to spot weld the cells together so I need to make the custom tabs to weld to the cells. http://tinyurl.com/4gxyvow

Regards

Bill Griffin

hi i have two battery packs ea. 24v 10ah originally from the currie enlighten this is the long curved pack that slides into the frame, i don't know if they are any good since they have been sitting so long , i dont know how i can charge them . voltage meter shows little life. i took one pack apart .does anyone think they can be brought back to life,and salvaging enough to make 1 pack for a currie i zip............will watch for suggestions thanx

Marco Norway

100 µW

so I need som help

I want to make some 48V battery pac's for my EV bike

it is one with a 450 watt motor

I both this http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=200824865118&ssPageName=ADME:X:AAQ:US:1123

I am thinking to us 15 pcs. of this:

http://www.ebay.com/itm/100-PCS-High-power-Lifepo4-18650-cells-A123-18650-Replacement-/200824865118

to make the 48V is this anough to make a 15-20 minnis ride?

and houw big a charger do I need to charge this "pack"

Greeting's Marco

999zip999

100 TW

I don't know what A123 replacment cells mean as far as quality in the ebay add. I think my next battey buy will be 32157's just triing to add up the price for a 2p pack @ 16.50 ea. plus shipping ect.

How about screw tops

How about screw tops

ridethelightning

1 MW

- Joined

- Jul 21, 2013

- Messages

- 2,010

cool or not, wood has a timeless habit of putting its hand up as an awesome material!

thanks for your research and enthusiasm Ypedal, on the nail every time!

thanks for your research and enthusiasm Ypedal, on the nail every time!

Similar threads

- Replies

- 5

- Views

- 870

- Replies

- 7

- Views

- 181