You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building the Blue Goose bent trike

- Thread starter BlueGoose

- Start date

Build threads are typically posted here:This is the first post of converting a recumbent trike to eassist.

Unexpected costs:

1. get a high output propane/mapp gas nozzle to build a frame for the battery

2. many, many connectors and multi-strand wire for everything

EBike Build Threads

endless-sphere.com

endless-sphere.com

Ah nuts, first post is always crp. Moving to builds....

What things do you need connectors and wires for? There could be less costly alternatives (parts or methods) to do the same job.

ccihon

100 W

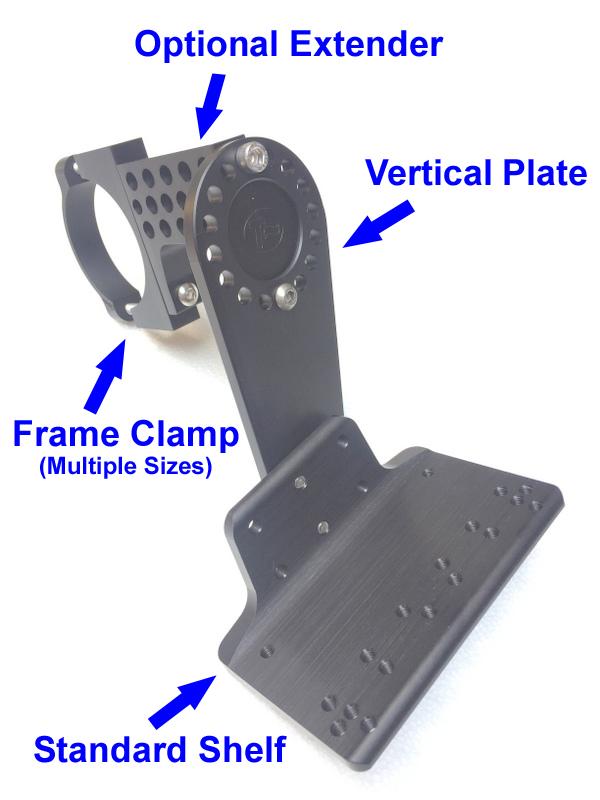

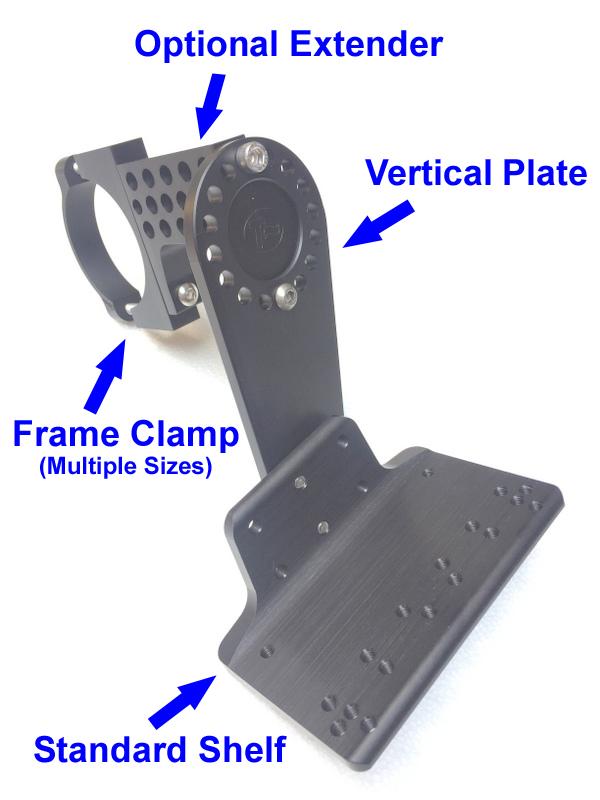

I have converted my trike, similar to your TT, to e-assist - I started using a hub motor solution, and have since adopted mid-drive. Sounds like your are handy and resourceful - I used a commercially available battery mount from TerraCycle that works well. The wiring and connectors do require a little improvisation as the trikes are longer-framed and often the harnesses designed for conventional bikes require extensions/modifications.

What motor/controller are you planning to use? Where do you plan to add the battery mount? Are you looking for gentle assist or a big-power trike? If you look over the build threads you will find a variety of solutions.

What motor/controller are you planning to use? Where do you plan to add the battery mount? Are you looking for gentle assist or a big-power trike? If you look over the build threads you will find a variety of solutions.

offGridDownUnder

1 kW

The wires and connectors are to connect batteries, motors, controllers, etc.

Can you say what choices you have made, or what possibilities you are considering? We can just follow along as you proceed, but there is a wealth of experience here, including the experience that "say, you can buy that ready made here".

My own build is in my signature. It works well now, and I think I've worked out the last change needed to the drive train - apart from gearing changes and maybe shimming the motor/belt over to maximize the possible rear tires. So far, I have been able to buy extension cables for my components.

I may finally have a reason to fabricate a cable as I'm thinking of adding reversing capability.

Can you say what choices you have made, or what possibilities you are considering? We can just follow along as you proceed, but there is a wealth of experience here, including the experience that "say, you can buy that ready made here".

My own build is in my signature. It works well now, and I think I've worked out the last change needed to the drive train - apart from gearing changes and maybe shimming the motor/belt over to maximize the possible rear tires. So far, I have been able to buy extension cables for my components.

I may finally have a reason to fabricate a cable as I'm thinking of adding reversing capability.

Thank you for the informative replies! This is the plan. The battery, motor, charger, and some connectors have been delivered.

Donor cycle: TerraTrike Cruiser recumbent trike 2002 (love it!)

Online consultation to aid selection, incredibly helpful: electrifybike.com

BB motor and integrated controller:

- CYC Photon

- Source: Electrifybike.com

Interface:

- CYCMotor DS103 + CYC app for Android phone

- Source: electrifybike.com

Auxiliaries:

- CYC magnetic brake cutoff

- 1 meter 10ga power extension with XT90-S connectors

- Source: electrifybike.com

Charger:

- Grin Satiator, cosmetically challenged for $100 discount, 48V nominal (also manages the 52v nominal)

- adapter cord to XT60M

- Source: ebikes.ca

Power supply system:

Battery:

- 52v LiFePO4 flat pack, 150mm x 150mm x 225mm (5.9 in x 5.9 in x 8.9 in)

- Source: Amazon, maker: BTRPower

Battery case for soft side battery:

- PA108 "Fat 50" ammo can, battery padding reused from shipping carton, Amazon

- Temporary: small tool bag for racktop use, harborfreight.com

Lighting:

- 24v to 48v headlight and taillight set w turn signals , generic Chinese, Amazon

- 12v 5 ft tall light whip, RGB, with chase light patterns, Amazon

Voltage step down:

- Generic Chinese 48v to 12v 20A

- Source: Amazon

Horn:

- 12v 2 tone automobile horns Source: harborfreight.com (blaaaat!)

- handlebar bell for rail trail (ding ding)

Unexpected costs

Wiring:

- an ever growing list of connectors and tools

- 2m 10 ga with male female XT90 connectors

- 5 pair XT60 connectors with pigtails

- 2 pair XT90S connectors with pigtails

- heat shrink butt connectors

- crimping pliers for heat shrink connectors

- 1 in heat shrink for XT90 and XT60 connectors

Still need wire extensions and specialty connectors for CYC

- brake sensors

- DS102 display

- speed sensor

-- edit --

Almost forgot. build frame to hold battery.

The Fat 50 ammo can is 12x9x7 inches, the usual recumbent universal mount cannot handle it on the TT Cruiser trike.

- 1" aluminum angle, 6 ft long

- aluminum brazing rods

- higher heat output nozzle for mapp gas

Donor cycle: TerraTrike Cruiser recumbent trike 2002 (love it!)

Online consultation to aid selection, incredibly helpful: electrifybike.com

BB motor and integrated controller:

- CYC Photon

- Source: Electrifybike.com

Interface:

- CYCMotor DS103 + CYC app for Android phone

- Source: electrifybike.com

Auxiliaries:

- CYC magnetic brake cutoff

- 1 meter 10ga power extension with XT90-S connectors

- Source: electrifybike.com

Charger:

- Grin Satiator, cosmetically challenged for $100 discount, 48V nominal (also manages the 52v nominal)

- adapter cord to XT60M

- Source: ebikes.ca

Power supply system:

Battery:

- 52v LiFePO4 flat pack, 150mm x 150mm x 225mm (5.9 in x 5.9 in x 8.9 in)

- Source: Amazon, maker: BTRPower

Battery case for soft side battery:

- PA108 "Fat 50" ammo can, battery padding reused from shipping carton, Amazon

- Temporary: small tool bag for racktop use, harborfreight.com

Lighting:

- 24v to 48v headlight and taillight set w turn signals , generic Chinese, Amazon

- 12v 5 ft tall light whip, RGB, with chase light patterns, Amazon

Voltage step down:

- Generic Chinese 48v to 12v 20A

- Source: Amazon

Horn:

- 12v 2 tone automobile horns Source: harborfreight.com (blaaaat!)

- handlebar bell for rail trail (ding ding)

Unexpected costs

Wiring:

- an ever growing list of connectors and tools

- 2m 10 ga with male female XT90 connectors

- 5 pair XT60 connectors with pigtails

- 2 pair XT90S connectors with pigtails

- heat shrink butt connectors

- crimping pliers for heat shrink connectors

- 1 in heat shrink for XT90 and XT60 connectors

Still need wire extensions and specialty connectors for CYC

- brake sensors

- DS102 display

- speed sensor

-- edit --

Almost forgot. build frame to hold battery.

The Fat 50 ammo can is 12x9x7 inches, the usual recumbent universal mount cannot handle it on the TT Cruiser trike.

- 1" aluminum angle, 6 ft long

- aluminum brazing rods

- higher heat output nozzle for mapp gas

Last edited:

AGS

100 W

- Joined

- Feb 13, 2023

- Messages

- 288

You may want to reconsider your horn. 12 volt horns draw a lot of current. You can get a 36 to 72 volt horn on Amazon that only draws a couple of hundred milliamperes.

Like this:

Like this:

Assembling the chainring

- used anti-seize compound before assembly ( Permatex Anti-seize Lubricant #80078 )

- torqued down using pins in the holes and a long bar.

Pins are 4mm, I used #10 screws

I used a long combination wrench. The loop prevents the bar from slipping off.

The chainring is fastened to the motor by screwing down the chainring cap. Both the chainring and cap are aluminum, is common for aluminum threads to gall and seize so I put a dab of anti seize on the threads before assembly, NOT grease. Antiseize has powdered metals in suspension to prevent galling. I used Permatex Anti-seize Lubricant #80078. I had a large jar on hand, you can get a small tube at auto stores or hardware stores which is more than enough for assembling the cap, axle, everything.

CYCmotor provides a poorly designed tool for torquing down the cap. You can’t measure torque and your hand can slip off the angled tool. I have bashed my knuckles too many times on cheap tools, no way was I going to depend on it.

I put pins in the holes and used a bar to torque down the cap. The hold are 4mm. I used #10 machine screws because they were on hand and fairly snug. The bar was a long combination wrench because the loop absolutely guaranteed the wrench would not slip off. (slip = bashed knuckles) I estimated the torque by feel.

I compared using their tool and the long bar. I torqued it down hard as possible with their short tool. Penciled a mark across the mating surfaces. Then I loosened and re-torqued with the long bar, and was able to move the chainring cap past the previous mark.

In my opinion the chainring cap is a poor design with 5 blind holes for tightening instead of 6 holes. If it has 6 holes it would be easy to make a better tool, just go across the diameter of the cap. But you can’t just add another hole. They are blind holes, and the inside of the cap has 5 little steps so the holes don’t go through. There is absolutely no reason to have individual steps instead of an entire ring around the inside. I think it’s to show off their machining and make things proprietary, and then they give you a poor tool because there are 5 holes.

I measured the bolt hole diameter to be 64.77 mm. I think it is 65mm allowing for errors. I measured between the hole outer diameters and inner diameters, and added the two. Done. Simple. If you have digital calipers (about $20)

- used anti-seize compound before assembly ( Permatex Anti-seize Lubricant #80078 )

- torqued down using pins in the holes and a long bar.

Pins are 4mm, I used #10 screws

I used a long combination wrench. The loop prevents the bar from slipping off.

The chainring is fastened to the motor by screwing down the chainring cap. Both the chainring and cap are aluminum, is common for aluminum threads to gall and seize so I put a dab of anti seize on the threads before assembly, NOT grease. Antiseize has powdered metals in suspension to prevent galling. I used Permatex Anti-seize Lubricant #80078. I had a large jar on hand, you can get a small tube at auto stores or hardware stores which is more than enough for assembling the cap, axle, everything.

CYCmotor provides a poorly designed tool for torquing down the cap. You can’t measure torque and your hand can slip off the angled tool. I have bashed my knuckles too many times on cheap tools, no way was I going to depend on it.

I put pins in the holes and used a bar to torque down the cap. The hold are 4mm. I used #10 machine screws because they were on hand and fairly snug. The bar was a long combination wrench because the loop absolutely guaranteed the wrench would not slip off. (slip = bashed knuckles) I estimated the torque by feel.

I compared using their tool and the long bar. I torqued it down hard as possible with their short tool. Penciled a mark across the mating surfaces. Then I loosened and re-torqued with the long bar, and was able to move the chainring cap past the previous mark.

In my opinion the chainring cap is a poor design with 5 blind holes for tightening instead of 6 holes. If it has 6 holes it would be easy to make a better tool, just go across the diameter of the cap. But you can’t just add another hole. They are blind holes, and the inside of the cap has 5 little steps so the holes don’t go through. There is absolutely no reason to have individual steps instead of an entire ring around the inside. I think it’s to show off their machining and make things proprietary, and then they give you a poor tool because there are 5 holes.

I measured the bolt hole diameter to be 64.77 mm. I think it is 65mm allowing for errors. I measured between the hole outer diameters and inner diameters, and added the two. Done. Simple. If you have digital calipers (about $20)

Last edited:

Looks like they're just sending you the cheapest possible version of an "adjustable angle grinder wrench".

If a better adjustable one or a non-adjustable one that already exists would fit, you could order one of those, or a similarly-designed type of tool (that would be easy to build) could be made.

If a better adjustable one or a non-adjustable one that already exists would fit, you could order one of those, or a similarly-designed type of tool (that would be easy to build) could be made.

Those would be useful! I considered purchasing an (inhales) Adjustable Gland Nut Wrench Spanner for Hydraulic Cylinders (whew). The ends of hydraulic cylinders have two indents for the pins. The wrench head has a 1/2 inch hole for a ratchet handle. If CYCMotor increased the width of the handles and punched a 3/8 inch square hole, that would solve the problem and allow you to use a torque wrench. It does not matter where you apply the torque, it does not need to be in the center of the wheel.

Impressions of my very first ebike ride with everything working:

HOLY SHIIII.... iii ... (doppler effect here) ... (fade) ... (coming back) ... iii...IIIITTTT !

i just gotta get everything tidied up with wire looms, fasten the battery to the frame instead of tying it onto the rear rack (could not wait), add lights, flags, and light whip for recumbent trike, and take it out on the road for real. This is gonna be fun.

HOLY SHIIII.... iii ... (doppler effect here) ... (fade) ... (coming back) ... iii...IIIITTTT !

i just gotta get everything tidied up with wire looms, fasten the battery to the frame instead of tying it onto the rear rack (could not wait), add lights, flags, and light whip for recumbent trike, and take it out on the road for real. This is gonna be fun.

FWIW, most build threads include pictures of things *as they are being built*, and details of what the build is intended to accomplish, and progress, etc.

They're more informative and fun that way.

They're more informative and fun that way.

ccihon

100 W

Sounds kinda similar to my BBSHD trike build - I had used a Harbor Freight Toolbag then an ammo can for a pack battery I used - when it died I went with a basic Hailong downtube battery - expensive, but worthwhile I think, are the battery mounting options sold by Terracycle (T-Cycle) - aluminum, very adjustable, and allows the battery to be mounted not only "out of the way" but low to keep center of gravity low on the trike. I see others perching a heavy pack battery on a rear rack or even between their legs on the boom - neither is optimal

T-Cycle Configurable Battery Mount2.00"

Electric drives on bikes and trikes are great for transportation and for enabling anyone to get out and ride, but until now, most people have had to hodgepodge together a way to carry the battery. Batteries are big, dense and valuable, and you don't want to just stick them anywhere. A rear rack...

hostelshoppe.com

Pics as requested. In retrospect I agree with ccihon, a downtube battery or similar compact format would have been much easier, and I might do that in the future. For now, I have the bulky battery and I'm dealing with it. The side view shows the rather large metal box. I'm stalled thinking of ways to run the wires through, I ordered printed panel mount sockets for XT90 (output) and XT60 (charge) and I need to run through 12V (lights).

Front view, CYC photon rests against the derailleur mast, display is on the mast, down by the pedals. The massive battery is on the seat while I finalize the wiring and battery box. There is not much room on the handlebars, just enough to grip and work the brakes. the thumb throttle is on the left side at the very top of the bar. I dunno, I might get an extension T for the bar end to mount the display and throttle.

Front view, CYC photon rests against the derailleur mast, display is on the mast, down by the pedals. The massive battery is on the seat while I finalize the wiring and battery box. There is not much room on the handlebars, just enough to grip and work the brakes. the thumb throttle is on the left side at the very top of the bar. I dunno, I might get an extension T for the bar end to mount the display and throttle.

ccihon

100 W

Looks like you will have it going soon. I don't knoew much about the Photon - is it basically a 1000 watt unit? It does appear that compared to my BBSHD, the chainline can be made more normal, though on a trike it is less of an ussie. Some pics of my build might give you ideas. I would recommend:

Strong brakes

Tough cassette and idler

Shift sensor along with careful shifting

Clipless pedals

Some photos will also show how I dealt with the throttle via a shifter add-on, and also the display. This was when I still had the pack battery in the tool bag. I have since also gone to fatter Big Ben tires and added a steering damper. You want a smooth stable ride at speed. I had a much older Terratrike before this one and found it quite twitchy, though I know the recent models are much improved.

endless-sphere.com

endless-sphere.com

Strong brakes

Tough cassette and idler

Shift sensor along with careful shifting

Clipless pedals

Some photos will also show how I dealt with the throttle via a shifter add-on, and also the display. This was when I still had the pack battery in the tool bag. I have since also gone to fatter Big Ben tires and added a steering damper. You want a smooth stable ride at speed. I had a much older Terratrike before this one and found it quite twitchy, though I know the recent models are much improved.

Hub to Mid conversion for a trike - talk me out of it.

by neptronix » Aug 13 2021 1:50pm Zero, i get your point about small wheels being a different story on a full recumbent versus my semi recumbents. I guess my recommendations assume you care about comfort and have full suspension already. And aren't lying on the back wheel. Suspension makes a...

endless-sphere.com

endless-sphere.com

Thank you, those are all good suggestions. ALWAYS necessary to have foot retention by any means, clipless pedals or straps. I chose straps, just my preference. I wondered about the idler, I will replace the stock plastic idler if it wears significantly, depending on my riding style. I will replace the brakes if they burn out. Agree with the careful shifiting, the torque sensor does not need a shift sensor but I need to be aware of not shifting under load. The Photon is nominal 750W, but over 1000W is possible.Looks like you will have it going soon. I don't knoew much about the Photon - is it basically a 1000 watt unit? It does appear that compared to my BBSHD, the chainline can be made more normal, though on a trike it is less of an ussie. Some pics of my build might give you ideas. I would recommend:

I like the display arrangement. I will probably change to that in a while.

Near completion.

I took it for a longer shake-down run to see if the battery mount would survive or tear off. It stayed on.

The CYC Photon rests against the derailleur mast. The wiring really needs organization. I used spiral wrap because it is forgiving. I think it will be neater on top of the frame.

The battery box support is a length of iron bed frame. I ordered panel-mount sockets to pass the wires through the side, then I can put the lid on. The lettering does not fit the theme, I will paint the box and other bits when the weather warms. Next spring. Sigh.

Piloting the trike is like zipping along in a Formula 1 car, reclined and a few inches from the ground. You look out between your toes. The hardest takeoff I did was Level 3, 42-32 gear, 20 inch wheel, it peaked at 1520 watts. Normal takeoff on Level 1 is 100W. So far I've only had it to Level 3 on the highest gear 42-11 and I max out at about 15 mph. The display shows 0mph because the speed sensor is not hooked up.

This build is taking unusually long because I have only a half hour each day to work on it. There are errors and unexpected design changes installing on a recumbent trike. More later.

I took it for a longer shake-down run to see if the battery mount would survive or tear off. It stayed on.

The CYC Photon rests against the derailleur mast. The wiring really needs organization. I used spiral wrap because it is forgiving. I think it will be neater on top of the frame.

The battery box support is a length of iron bed frame. I ordered panel-mount sockets to pass the wires through the side, then I can put the lid on. The lettering does not fit the theme, I will paint the box and other bits when the weather warms. Next spring. Sigh.

Piloting the trike is like zipping along in a Formula 1 car, reclined and a few inches from the ground. You look out between your toes. The hardest takeoff I did was Level 3, 42-32 gear, 20 inch wheel, it peaked at 1520 watts. Normal takeoff on Level 1 is 100W. So far I've only had it to Level 3 on the highest gear 42-11 and I max out at about 15 mph. The display shows 0mph because the speed sensor is not hooked up.

This build is taking unusually long because I have only a half hour each day to work on it. There are errors and unexpected design changes installing on a recumbent trike. More later.

Ordered a few more parts from Electrifybike. They were very responsive. Then it will be on the road!

1. Main wiring harness with 4 leads, 2 for brake sensors.

2. 650mm long speed sensor extension. Most of the other standard length Photon wires were just fine.

1. Main wiring harness with 4 leads, 2 for brake sensors.

2. 650mm long speed sensor extension. Most of the other standard length Photon wires were just fine.

I'm considering a similar build for one of our Kettwiesel delta trikes, and debating whether to go with a 42-tooth chainring or a 50-tooth chainring. Got any insights based on how yours climbs with the a 42? (I wouldn't mind having a slightly higher top-end speed, but don't really need it and definitely don't want to compromise hill climbing ability.)

We occasionally link our 2 trikes together (one front wheel gets removed and the front fork of that trike hitches to the bumper of the other). That makes for a fun but heavy and slow combination - and I suspect that climbing with over 400 lbs of trikes + riders just would not work with a 50-tooth chainring...

PS, what did you use to mount your display? Is that a t-cycle cockpit mini-T? A different cockpit mount?

We occasionally link our 2 trikes together (one front wheel gets removed and the front fork of that trike hitches to the bumper of the other). That makes for a fun but heavy and slow combination - and I suspect that climbing with over 400 lbs of trikes + riders just would not work with a 50-tooth chainring...

PS, what did you use to mount your display? Is that a t-cycle cockpit mini-T? A different cockpit mount?

Last edited:

Those Kettwiesel deltas are marvelous! I have seen a long train of them linked together.I'm considering a similar build for one of our Kettwiesel delta trikes, and debating whether to go with a 42-tooth chainring or a 50-tooth chainring. Got any insights based on how yours climbs with the a 42? ...

PS, what did you use to mount your display? Is that a t-cycle cockpit mini-T? A different cockpit mount?

IMO, choose the 42T chainring and see how that works.

I had a 32-42-52 chain ring and 11-32 cassette, 26" driving wheel. I am not in shape and to get up hills I was using 32-32, and changed to a 20" wheel. I could *almost* get up the hills with 42T chainring, so I chose a 42T Photon chainring and went back to the 26" driving wheel. The 42T is fast enough, getting me over 20mph on the flat, with pedaling. The entire system including overweight pilot is about 350 lbs.

T-cycle miniT yes.

The Blue Goose is completed! For now. Until it gets more bling or better lighting

Installing the CYC Photon was simple. A recumbent trike has a super long chain line, so aligning it exactly was not an issue. Packaging and mounting the non-standard LiFePO4 battery was a pain in the butt. I would not do it again. For any recumbent trike I suggest a standard Dolphin style Lion battery. For a charger, I do suggest the programmable Grin Satiator. I set my Satiator to 85% charge to preserve battery life. It stops charging when it reaches that level, and I've forgotten and left it connected for a day or so without damage. But it is not suggested.

The candidate trike, a TerraTrike Cruiser, has vertical handlebars and very limited space for accessories. Like none. I added 3" vertical riser from AliExpress (don't hate me) and it is not good quality but it makes space for the Minoura T-mount for the display.

Overall view. The ammo can looks dashing. Kinda hidden by the panniers.

Wiring harness was VERY challenging for a recumbent trike. It needed a 1 meter power extension, 2x200mm speed sensor extension, and the display/throttle was barely long enough. Display is DS103 on the top left handlebar. Throttle is on the bottom right side bar.

I think the wiring runs are very clean and well hidden. I wrapped the 3 main cables in black spiral loom and pulled them underneath. Everything is held in place with industrial strength adhesive Velcro. I used the adhesive stuff for years for the lighting, and I trust it. No visible cable ties!

Battery, yeah, it's a beast. The LiFePO4 battery is 6" x 6" x 9". It fits in the larger 50cal FAT can, which has room for a 12V down converter for accessories. The angle iron from a bed frame is not the look I wanted. The ports are XT90 out, 12v out, XT60 charging. The black panel mount blanks were printed, from ebay.

I chose the LiPoly battery because I am new to electric bikes, and read horror stories of Lion batteries burning, and more importantly, they had to be watched while charging. I have so many things to do, caring for family, I would forget and let it overcharge. I wanted 52V 20Ah. The only LiPoly choice was from BTPower, soft packed, protected only by a shrink wrap. It is 6x6x9 in, and I spent over a month trying to find appropriate boxes. I finally settled on the huge ammo can, mounted cantilever from the frame, fastened at a third point in the back on the dropout arms.

Installing the CYC Photon was simple. A recumbent trike has a super long chain line, so aligning it exactly was not an issue. Packaging and mounting the non-standard LiFePO4 battery was a pain in the butt. I would not do it again. For any recumbent trike I suggest a standard Dolphin style Lion battery. For a charger, I do suggest the programmable Grin Satiator. I set my Satiator to 85% charge to preserve battery life. It stops charging when it reaches that level, and I've forgotten and left it connected for a day or so without damage. But it is not suggested.

The candidate trike, a TerraTrike Cruiser, has vertical handlebars and very limited space for accessories. Like none. I added 3" vertical riser from AliExpress (don't hate me) and it is not good quality but it makes space for the Minoura T-mount for the display.

Overall view. The ammo can looks dashing. Kinda hidden by the panniers.

Wiring harness was VERY challenging for a recumbent trike. It needed a 1 meter power extension, 2x200mm speed sensor extension, and the display/throttle was barely long enough. Display is DS103 on the top left handlebar. Throttle is on the bottom right side bar.

I think the wiring runs are very clean and well hidden. I wrapped the 3 main cables in black spiral loom and pulled them underneath. Everything is held in place with industrial strength adhesive Velcro. I used the adhesive stuff for years for the lighting, and I trust it. No visible cable ties!

Battery, yeah, it's a beast. The LiFePO4 battery is 6" x 6" x 9". It fits in the larger 50cal FAT can, which has room for a 12V down converter for accessories. The angle iron from a bed frame is not the look I wanted. The ports are XT90 out, 12v out, XT60 charging. The black panel mount blanks were printed, from ebay.

I chose the LiPoly battery because I am new to electric bikes, and read horror stories of Lion batteries burning, and more importantly, they had to be watched while charging. I have so many things to do, caring for family, I would forget and let it overcharge. I wanted 52V 20Ah. The only LiPoly choice was from BTPower, soft packed, protected only by a shrink wrap. It is 6x6x9 in, and I spent over a month trying to find appropriate boxes. I finally settled on the huge ammo can, mounted cantilever from the frame, fastened at a third point in the back on the dropout arms.

Last edited:

Yes, the steering is very twitchy with the electric assist at speed. What was the source of your steering damper?Looks like you will have it going soon. ... This was when I still had the pack battery in the tool bag. I have since also gone to fatter Big Ben tires and added a steering damper. You want a smooth stable ride at speed. I had a much older Terratrike before this one and found it quite twitchy, though I know the recent models are much improved.

I just read your original post. Question answered. Thank you for the info!

ccihon

100 W

With my new trike, the damper solves an oscillation issue, but it's similar to what I used on the old TT. It did improve stability somewhat. Almost any motorcycle damper can be adapted. I actually thought the newer TT solved the issues by design... Mine was a very early one. One area you may want to beef up is the power side idler... Are they still using urethane skateboard wheel style thing? You can retrofit steel toothed idler.. noiser but won't get sawed in half by the motor

Last edited:

Ah, the problems caused by adding a strong electric motor! I was never able to pedal fast enough to get the "death wobble" . I ordered a steering damper and expect it this weekend. After the damper arrives I will dry-fit and order an attachment to the frame and appropriately sized bolts and nuts.With my new trike, the damper solves an oscillation issue, ///One area you may want to beef up is the power side idler... Are they still using urethane skateboard wheel style thing? You can retrofit steel toothed idler.. noiser but won't get sawed in half by the motor

Yes, it has a plastic idler. I expected the motor would cause excessive wear and I would need a metal idler, but not yet because it is another 130$ from Tcycle. Any suggestions are appreciated. Sadly, I no longer have access to a Bridgeport mill, but I do have a drill press and my old machining knowledge.

Similar threads

- Replies

- 0

- Views

- 2,062

- Replies

- 15

- Views

- 2,092

- Replies

- 15

- Views

- 5,211

- Replies

- 16

- Views

- 2,164