Samd

10 MW

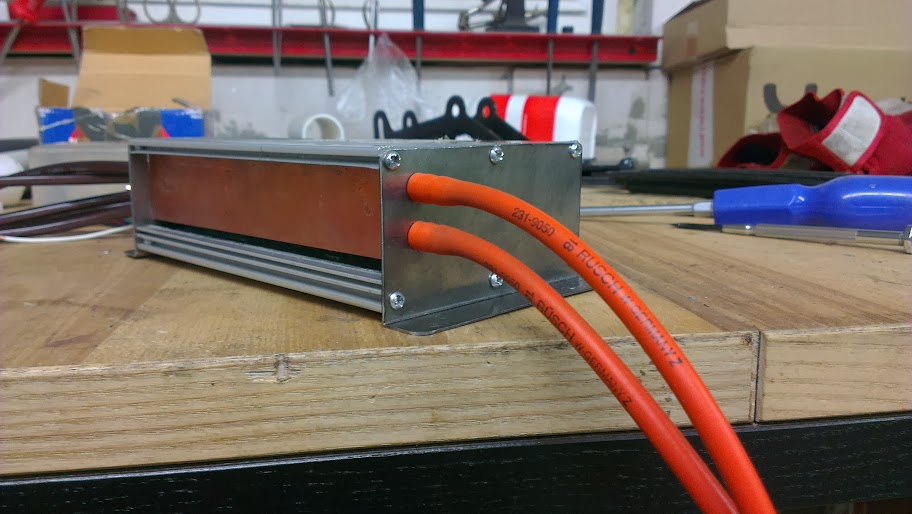

I can't stress enough the simple yet brutal effectiveness of what Kepler has done.

Effectively increasing the radiant case surface area by a factor between 10 and 100 (or more) far eclipses any active/complex cooling methods in my book.

And hanging by the FET bar has been successful for me on a dozen or so installs.

Gets the controller away from the rear wheel spray. I like to hose my bike down after a mudding.

Effectively increasing the radiant case surface area by a factor between 10 and 100 (or more) far eclipses any active/complex cooling methods in my book.

And hanging by the FET bar has been successful for me on a dozen or so installs.

Gets the controller away from the rear wheel spray. I like to hose my bike down after a mudding.