Ok, so I finally got around to doing some proper tests on this setup.

I tested this on a slightly breezy 18C day. The test run was 150m up a mild grade not too steep to stall the motor, so I didn't have to pedal, but still steep enough to generate a decent amount of heat for testing. I'm currently running on 21AH 12S LiPo. For the test I set my CA to limit current to 90A, so 4Kw of power...at least at the start of each run.

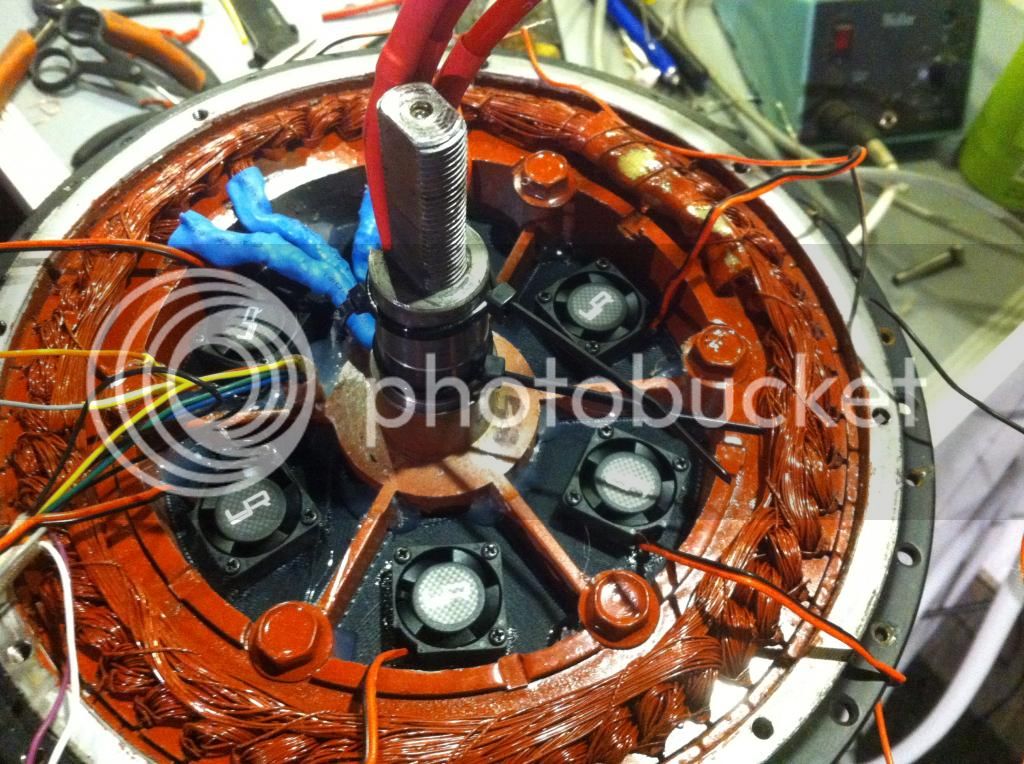

I barely have enough time to scratch myself these days, so I didn't do a fully scientific multiple test scenario, but I did manage 5 runs. One with no fans, and 4 with fans a different voltages. This test was as much about proving the concept as it was seeing what difference in heat dissipation the fan speeds make. It was interesting for me to see that there wasn't a huge difference between running the fans at 12V and 15V. This is good for me to know as these are only 12V rated fans (although good quality ones), so running them at anything north of 14V for prolonged periods is risky as it could burn them out. Running them at 18V is only something I would ever do if the motor looked like it was about to melt down, or I was escaping a zombie apocalypse. :lol:

Anyway, I won't ramble on too much, and try and let the video/graph speak for themselves.

[youtube]P-VXS-aZZkU[/youtube]

Apologies for the lengthy video, but it's necessary to validate my results below.

In order to see the temps and control the fan speed, I put together a little 'package' that sits where my CA used to sit. It consists of a DC-DC converter, voltage display, temp display, and a fan (since changed to 2 fans in series) to cool the DC-DC converter. In order to mount it, I built up layers of hot glue so that I could use double sided tape to attach it to the underside of my frame from the inside. It's mostly been working well and hasn't dislodged since I've properly mounted it.

The only issue I've faced as been the adjuster for the voltage. As in the second photo above, I originally epoxied a paper clip to the pot with the idea of gluing a valve cap to that. That failed, then I tried the same with a piece cut off screw driver, then with hot glue, then with super glue, which all failed. I think the problem is the small size of the pot does not offer enough surface area to properly attach anything. If anyone has any suggestions, I'm all ears as I've yet to really think of a good alternate solution to just trying again with more glue and hoping it works.

I hope that others see my success with this approach, and take if further. For me, so far, riding through water, dust, and mud have not negatively effected the fans. I'll find out if they can survive the 40C ambient temps of summer around this part of Australia soon, but I suspect they will be fine. I won't hesitate to recommend doing this mod to others, as it was relatively easy in comparison to some other mods like oil, or water cooling.

I'll likely be modding my other motor (HS4080) with the same mod at some stage. I might try and document it when I do it to show others how they might do the same, if that would be useful. 8)

Cheers