You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Destroyed! A warning to those using freewheel cranks....

- Thread starter boostjuice

- Start date

MitchJi

10 MW

Hi Miles,

:wink: (sorry, I couldn't resist

:wink: (sorry, I couldn't resist  ).

).

Mitch said:What are the chances of you coming up with a solution? Maybe an additional optional support bearing for your Eno FW's?

Jim proposed having White make a FW with two bearings. Which isn't more exclusive than his current solution.Miles said:Fine. I'm not keen on "exclusive" parts, though.....

Another design using "exclusive" partsMiles said:In case the design I was proposing wasn't clear:...

boostjuice

10 kW

Mitch, Thankyou for approaching Sickbikeparts with that request. I hope they can come up with something innovative and widely useable. I do however fear that in order to retain the use of sealed cartridge bearings in a twin bearing design - a key benefit of an ENO - it would lead to an excessively wide freewheel as a bi-product. However despite this i guess they would likely still be usable for the majority of users with extended bottom bracket spindles. (Not me unfortunately  )

)

As always, beautiful CAD work Miles - just as i'd imagined it from your earlier explanation :wink: . Unfortunately for me however, it turns out that I can't even afford an extra 8mm inbound clearance between my Freewheel and BB cup as im running a standard length BB spindle (128mm x 83mm BB).

I've just recieved one of the Recently released ACS 'Crossfire' series freewheels in 22T to try out next in place of the failed Dicta. Being CNC mill/laser cut, they are a HUGE step up in quality from the old largely stamped Dicta and ACS 'Claws' line (another i was considering). They feature a quality finish, 3 synchronously engaging pawls just like the ENO, offer very low overrunning resistance, are reasonably quiet, and feature twin angular contact bearings with minuscule lateral freeplay. If the ratchets are rotary/laser cut like an ENO, rather than being broach stamped such as in the 'Claws' line (and all Dicta's I might add), then there is a good chance that the parent metallurgy is stronger as it can be of a harder material before broaching and subsequent case hardening.

To try and ascertain this I will post pictures of their internals soon!

I also ordered an ACS Crossfire freewheel in 13T to have a play with as I've not been happy with the excessive over-running resistance and 'roughness' of bearing rotation of my Odyssey 13T i planned to use for my next build. Just like the 22T Crossfire, it's smoother, quieter, rolls free'er and is much more nicely finished than the Odyssey.

As always, beautiful CAD work Miles - just as i'd imagined it from your earlier explanation :wink: . Unfortunately for me however, it turns out that I can't even afford an extra 8mm inbound clearance between my Freewheel and BB cup as im running a standard length BB spindle (128mm x 83mm BB).

I've just recieved one of the Recently released ACS 'Crossfire' series freewheels in 22T to try out next in place of the failed Dicta. Being CNC mill/laser cut, they are a HUGE step up in quality from the old largely stamped Dicta and ACS 'Claws' line (another i was considering). They feature a quality finish, 3 synchronously engaging pawls just like the ENO, offer very low overrunning resistance, are reasonably quiet, and feature twin angular contact bearings with minuscule lateral freeplay. If the ratchets are rotary/laser cut like an ENO, rather than being broach stamped such as in the 'Claws' line (and all Dicta's I might add), then there is a good chance that the parent metallurgy is stronger as it can be of a harder material before broaching and subsequent case hardening.

To try and ascertain this I will post pictures of their internals soon!

I also ordered an ACS Crossfire freewheel in 13T to have a play with as I've not been happy with the excessive over-running resistance and 'roughness' of bearing rotation of my Odyssey 13T i planned to use for my next build. Just like the 22T Crossfire, it's smoother, quieter, rolls free'er and is much more nicely finished than the Odyssey.

Which is exclusive to him.MitchJi said:Jim proposed having White make a FW with two bearings. Which isn't more exclusive than his current solution.

No, anyone is free to copy itMitchJi said:Another design using "exclusive" parts:wink: (sorry, I couldn't resist

).

Sounds promising....boostjuice said:I've just recieved one of the Recently released ACS 'Crossfire' series freewheels in 22T to try out next in place of the failed Dicta. Being CNC mill/laser cut, they are a HUGE step up in quality from the old largely stamped Dicta and ACS 'Claws' line (another i was considering). They feature a quality finish, 3 synchronously engaging pawls just like the ENO, offer very low overrunning resistance, are reasonably quiet, and feature twin angular contact bearings with minuscule lateral freeplay. If the ratchets are rotary/laser cut like an ENO, rather than being broach stamped such as in the 'Claws' line (and all Dicta's I might add), then there is a good chance that the parent metallurgy is stronger as it can be of a harder material before broaching and subsequent case hardening.

http://www.bmxultra.com/reviews/acs_crossfire_freewheel.htm

boostjuice

10 kW

Miles said:Have you come to a final verdict on the 'Crossfires', bj?

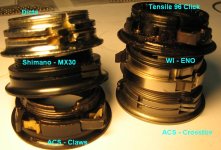

You can all decide for yourselves.....amongst other choices

markobetti

10 kW

- Joined

- Jul 16, 2009

- Messages

- 620

Wow , Boostjuice , what is your opinion since you have the museum ; the best long lasting choice ?

; the best long lasting choice ?

boostjuice

10 kW

Miles said:'Museum of freewheel'.

Thanks!

Dammit, I knew I should have charged an entry fee

markobetti said:Wow , Boostjuice , what is your opinion since you have the museum; the best long lasting choice ?

WI ENO wins if you don't need dual angular contact bearings, ACS Crossfire the alternative if you do, or need <16T.

Both feature triple synchronous engaging pawls rather than the others which use two (odyssey excepted), so torque capacity is better. The Crossfire has very low noise and over-running drag, the ENO is intermediate in comparison.

The ENO pictured has been used for freewheel crank duties for ~300Km and its ratchet/pawls look completely unscathed from that sort of torque loading, so its got the locking strength, and definitely superb machining quality/tolerances as you can see.

Don't bother with the rest IMHO, Crossfires are basically as cheap or cheaper than the others of inferior build quality.

The Crossfire is finished very nicely and obviously a huge step up in quality from the Claws line. The ratchet profile is laser cut rather than broached like most cheaper freewheels so it 'should' be that the parent metal is harder than the lesser types (Note: ENO ratchet profile is rotary milled, from very strong parent metal).

The tensile 96click looks nice, but has way too much freewheeling drag. Also, because it uses the pawls/springs from the 60 click version, they don't seat properly in the valleys of the ratchet profile. Rather, they contact the very tip of each ratchet tooth = inferior design, handicapped torque handling.

Also, Crossfire 13T is the better option compared with the Odyssey 13T. Lower freewheeling drag and lateral bearing play and looks way cooler! Both feature 3 synchronous engagement pawls, so strength should be much the same.

Solcar

10 kW

Boostjuice, thanks very much. I enjoyed the exhibit. Great information, I'll look out to obtain the ACS crossfire.

MitchJi

10 MW

Hi bj,

Any chance of fixing the links or reposting the pictures?

Thanks Amberwolf!

Any chance of fixing the links or reposting the pictures?

boostjuice said:You can all decide for yourselves.....amongst other choices

...

amberwolf said:By chance, I happened to save all those when I saw them, as I am considering modifying some existing freewheels with certain features I saw on those (which I expect to fail but still may try).

Attached below, not necessarily in the same order they used to be:

Thanks Amberwolf!

By chance, I happened to save all those when I saw them, as I am considering modifying some existing freeewheels with certain features I saw on those (which I expect to fail but still may try).

Attached below, not necessarily in the same order they used to be:

Attached below, not necessarily in the same order they used to be:

Attachments

-

FW_lineup1.JPG83 KB · Views: 1,687

FW_lineup1.JPG83 KB · Views: 1,687 -

FW_lineup2.JPG62 KB · Views: 5,430

FW_lineup2.JPG62 KB · Views: 5,430 -

FW_lineup4.JPG59.2 KB · Views: 5,434

FW_lineup4.JPG59.2 KB · Views: 5,434 -

ENO_closeup.JPG51.8 KB · Views: 5,434

ENO_closeup.JPG51.8 KB · Views: 5,434 -

Crossfire_closeup.JPG75.8 KB · Views: 5,434

Crossfire_closeup.JPG75.8 KB · Views: 5,434 -

Claws_closeup.JPG43.3 KB · Views: 5,434

Claws_closeup.JPG43.3 KB · Views: 5,434 -

Tensile96Clk_closeup.JPG38.6 KB · Views: 5,430

Tensile96Clk_closeup.JPG38.6 KB · Views: 5,430 -

ShimanoMX30_closeup.JPG45 KB · Views: 5,430

ShimanoMX30_closeup.JPG45 KB · Views: 5,430 -

Dicta_closeup.JPG62.5 KB · Views: 5,430

Dicta_closeup.JPG62.5 KB · Views: 5,430 -

WI_ENO.jpg45.7 KB · Views: 5,430

WI_ENO.jpg45.7 KB · Views: 5,430 -

ACS_Claws.jpg49.4 KB · Views: 5,430

ACS_Claws.jpg49.4 KB · Views: 5,430 -

Shimano_MX30.jpg45.8 KB · Views: 5,434

Shimano_MX30.jpg45.8 KB · Views: 5,434 -

Dicta_flanged.jpg51.7 KB · Views: 5,430

Dicta_flanged.jpg51.7 KB · Views: 5,430 -

FW_ratchet_lineup.JPG58.5 KB · Views: 5,430

FW_ratchet_lineup.JPG58.5 KB · Views: 5,430 -

ratchet_lineup_half1.JPG38.5 KB · Views: 5,430

ratchet_lineup_half1.JPG38.5 KB · Views: 5,430 -

ratchet_lineup_half2.JPG42.9 KB · Views: 5,434

ratchet_lineup_half2.JPG42.9 KB · Views: 5,434 -

Inner_driver_lineup.JPG62.6 KB · Views: 5,434

Inner_driver_lineup.JPG62.6 KB · Views: 5,434 -

Ratchet_pawl_Crossfire_vs_ENO.JPG62.6 KB · Views: 5,434

Ratchet_pawl_Crossfire_vs_ENO.JPG62.6 KB · Views: 5,434 -

Ratchet_pawls_mixed1.jpg77 KB · Views: 5,430

Ratchet_pawls_mixed1.jpg77 KB · Views: 5,430 -

Ratchet_pawls_mixed2.JPG74.3 KB · Views: 5,434

Ratchet_pawls_mixed2.JPG74.3 KB · Views: 5,434 -

13T_ACS_crossfire_vs_Odyssey_FW_1.JPG39.7 KB · Views: 5,434

13T_ACS_crossfire_vs_Odyssey_FW_1.JPG39.7 KB · Views: 5,434 -

Dicta_vs_Dicta.JPG47.2 KB · Views: 5,434

Dicta_vs_Dicta.JPG47.2 KB · Views: 5,434 -

13T_ACS_crossfire_vs_Odyssey_FW_2.JPG23 KB · Views: 5,430

13T_ACS_crossfire_vs_Odyssey_FW_2.JPG23 KB · Views: 5,430 -

13T_ACS_crossfire_vs_Odyssey_FW_3.JPG28.4 KB · Views: 5,434

13T_ACS_crossfire_vs_Odyssey_FW_3.JPG28.4 KB · Views: 5,434

boostjuice

10 kW

Yeah sorry guys. I just changed ISP, and the new one is taking forever and stuffing me around with my new FTP webspace setup. AW saves the day in the meantime

comradegerry

100 W

I just picked up a Tensile Onza 60 click from Ebay to experiment with...

It has dual bearings and looks to be decent build quality, I plan to grind off the cog and get somebody to weld on a flange similar to the WI ENO type....

Would this work for a through the crank setup, moderate power, is it even worth trying or am I best sticking to the flanged ENO I currently have installed?.

I will post up some pics of it opened up when it arrives for the curious.

http://www.ebay.com/itm/260910437496?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649

It has dual bearings and looks to be decent build quality, I plan to grind off the cog and get somebody to weld on a flange similar to the WI ENO type....

Would this work for a through the crank setup, moderate power, is it even worth trying or am I best sticking to the flanged ENO I currently have installed?.

I will post up some pics of it opened up when it arrives for the curious.

http://www.ebay.com/itm/260910437496?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649

recumpence

1 GW

Hey Guys,

I just wanted you to know I am developing a freewheeling crank setup that uses a second support bearing to solve this problem and will accept normal 130mm BCD chainrings. I expect to have them in stock in about 30 days.

I am sorry to hijack the thread. But, I thought you might want to know.

Matt

I just wanted you to know I am developing a freewheeling crank setup that uses a second support bearing to solve this problem and will accept normal 130mm BCD chainrings. I expect to have them in stock in about 30 days.

I am sorry to hijack the thread. But, I thought you might want to know.

Matt

fizzit

10 kW

Cost estimate? Or if I have to ask... :lol:

recumpence

1 GW

That depends on what you are looking for.fizzit said:Cost estimate? Or if I have to ask... :lol:

The bottom bracket requires a longer spindle for room for the second bearing. So, it requires a bearing, lengthened bottom bracket, bearing spacer, sprocket adaptor, crank arms, chainrings, and freewheel. The freewheel can be a basic flanged freewheel or a White Industries flanged freewheel. I would guess it will be maybe $250 or $300? I have to total up all the parts that go into this and get back to you.

Matt

comradegerry

100 W

Hi Matt

That sounds real interesting look forward to seeing the idea develop into another cool must have product.

Best wishes for Christmas and New Year.

Gerard

That sounds real interesting look forward to seeing the idea develop into another cool must have product.

Best wishes for Christmas and New Year.

Gerard

daveyjones97

10 W

- Joined

- Dec 7, 2011

- Messages

- 77

i havent read the thread thouroughly as its late here, but im going to make an ebike using the rear disc brake hub mount to mount the drive sprocket for the motor. the disc brake can either be swapped for a v brake or relocated to the motor shaft. are there any major disadvantages to that? the fear of freewheel failure in town traffic or a fast downhill makes me want my mummy.

So, where will you have the motor freewheel?

You could move the disc brake to a jackshaft, if the freewheel was on the motor shaft (or on the motor side of the jackshaft).

Obviously, the freewheel can't come before the disc brake

You could move the disc brake to a jackshaft, if the freewheel was on the motor shaft (or on the motor side of the jackshaft).

Obviously, the freewheel can't come before the disc brake

I see ACS are advertising Crossfire Pro freewheels, now:

http://www.acsbmx.com/crossfire.html

"Crossfire Pro Freewheels

Our best freewheels for uncompromising performance. CNC wire pawls and steps for the ultimate precision. Each pawl engages 2 steps for maximum grip. 60 steps for engagement every 6 degrees. Nickel-plated sprocket ring.

3/32" x 16T or 18T"

http://www.acsbmx.com/crossfire.html

"Crossfire Pro Freewheels

Our best freewheels for uncompromising performance. CNC wire pawls and steps for the ultimate precision. Each pawl engages 2 steps for maximum grip. 60 steps for engagement every 6 degrees. Nickel-plated sprocket ring.

3/32" x 16T or 18T"

Similar threads

- Replies

- 25

- Views

- 3,104

- Replies

- 12

- Views

- 10,704

- Replies

- 14

- Views

- 8,450

- Replies

- 35

- Views

- 17,308