Biff

100 W

Yep, stiffness is a big issue with the CSIRO motor. Once those winings get warm, the stator turns to jelly, bends, makes contact with the rotor (there is a 2mm airgap beween the stator and the rotor) then you are screwed. It is a good idea to have a support structure to the system, it might help you get a bit of the heat out as well.Kingfish said:Hiya Biff

Copper fill

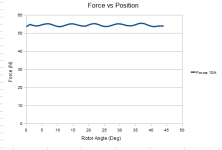

I ran several simulations that did show marked improvement when the windings were filled to their maximum, however I am not convinced that the stator could be constructed having any rigidity without some sort of support. For that I allowed 2mm between the windings to provide ribbing, and likely a perimeter band as well. I haven’t decided if the sides facing the magnets will have a thin facing sheet as well: Everything depends upon flatness, and maintaining that flatness during some very high lateral forces. Not having built one before I tend to err on the conservative. The losses are visibly noted in the graphs below.

Kingfish said:Hell crazy on Lua

I do have some graphs to post though. Read, tweaked, read some more, tweaked some more – applied the same scripts to both the 9C 2806 RF and the 16p18t AF (with obvious customizations) and… it just begs for more questions. There’s even a Halbach version of the 16p18t… Biggest change was that I included the Force and the Torque for a full 2-pole cycle. The Force is calculated using the mo_blockintegral(18) method.

I found that Lorentz force blockintegral(11) which you initally suggested, provided more expected results for force. I'll have a look at your scripts and post some more feedback.

Kingfish said:I do want to review the maximum Tesla that can be crammed through a thin back iron; that is key to factoring out design and manufacturing. I wonder what the permeability of CRS is.

Twiddlin’ KF

What is CRS? Permiabilty and saturation are similar but not related. Pure iron saturates at around 2.2T Laminated Iron at around 2T, Laminated Cobalt at around 2.3T. For high permiability you want Nickle. For Nickle see Mu Metal for an extreme example http://en.wikipedia.org/wiki/Mu-metal, or Carpenter "49" for something you can get in laminations, but you will notice that Carpenter 49, saturates at around 1T

http://cartech.ides.com/ImageDisplay.aspx?E=207&IMGURL=%2fCarpenterImages%2fC-MagneticControlled%2f01-EA01-CarpenterHighPermiability49Alloy%2f05_EA01_RotorGrade.gif&IMGTITLE=Rotor+Grade+-+Results+at+0.014%22+%280.36%22+mm+thick%29

from the rotor spec link here: http://cartech.ides.com/datasheet.aspx?i=103&e=207&c=TechArt

Carpenter Hyperco50 (cobalt alloy) is high saturation 2.4T , http://www.cartech.com/ssalloysprod.aspx?id=2360

From the simulations, I don't think the high flux dencity of the back iron is going to cause a significant problem for this motor like I initally thought. I haven't studied the simulations extremely closely, so I could still fall on either side of the fence for this decision.

-ryan