KWTri said:

08 2019 10:10pm

1) As regards the TSDZ2 motor itself are there more recent revisions, and if so, what should I look for to get the most recent version?

Motor revision 1 (2017-2018, 2019?) Straight cut main gear / spur gear, Silver spider, Black spider? Main gear plastic cover has 3 screws, Original weather seals

Motor revision 2 (2018? 2019-) Helical cut main gear / spur gear (should be quieter), Black spider, Main gear plastic cover has 4 screws, Better weather seals

KWTri said:

My other questions have mostly to do with which display to order to install the firmware on. As stated earlier I need this to be as stable and user friendly as possible for a non technical family member.

2) What is the current best device for installing the firmware? (I am on a bit of a budget, so would like to avoid the 850c as it is more expensive both for the device and for the bootloader box, which together add well over $100 to the build. However if that is the best option, so be it.)

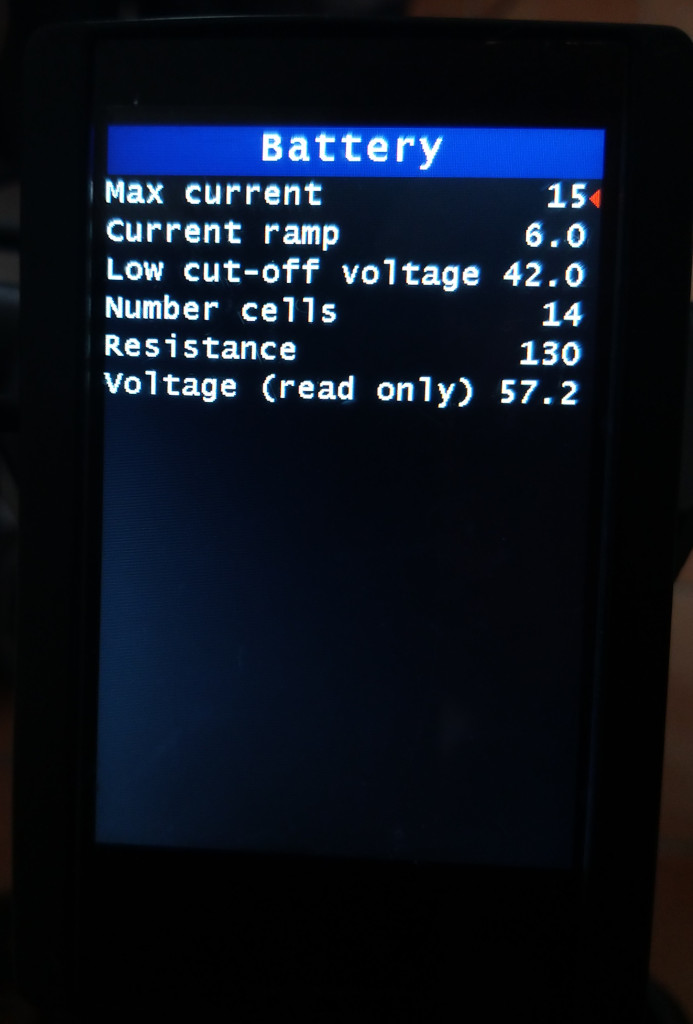

TBH right now it remains the KT LCD3 with STLINK. You can run the latest firmware which is very feature rich and stable (0.20). I don't believe you would need to upgrade again. If you want eventual Strava integration the SW102, but this could be some time.

KWTri said:

4) Will the LCD3 continue to be developed, and what are it's limitations?

Memory. Currently no s/w limitations, multipoint torque sensor calibration in the future could be missing and new features not yet thought of. The display has great visibility, and seems pretty weather proof.

KWTri said:

5) My other thought was the SW102, as it is smaller and cheaper than the 850c and uses the same STv2 programming cable. Is the Firmware for this device at a stable point?

No not currently. Wireless flashing still in progress, firmware itself a work in progress.

KWTri said:

And a few questions about the motor install itself.

6) I'm installing on a road bike, a specialized carbon frame. Are there any particular problems with installing this more onto a road racing style frame?

Yes potentially. Carbon frames will have a lot of material around the bottom bracket. Generally too much to fit the TSDZ2

KWTri said:

8) Lastly, considering we do some touring in Colorado, how well does the motor handle sustained climbing for say an hour or more? What settings would be best for this scenario?

You would want to limit the power to 200-300 watts unless you do a cooling mod. TBH that is enough it is more than double what a fit person can output themselves