Philosoraptor

1 W

- Joined

- Dec 7, 2021

- Messages

- 54

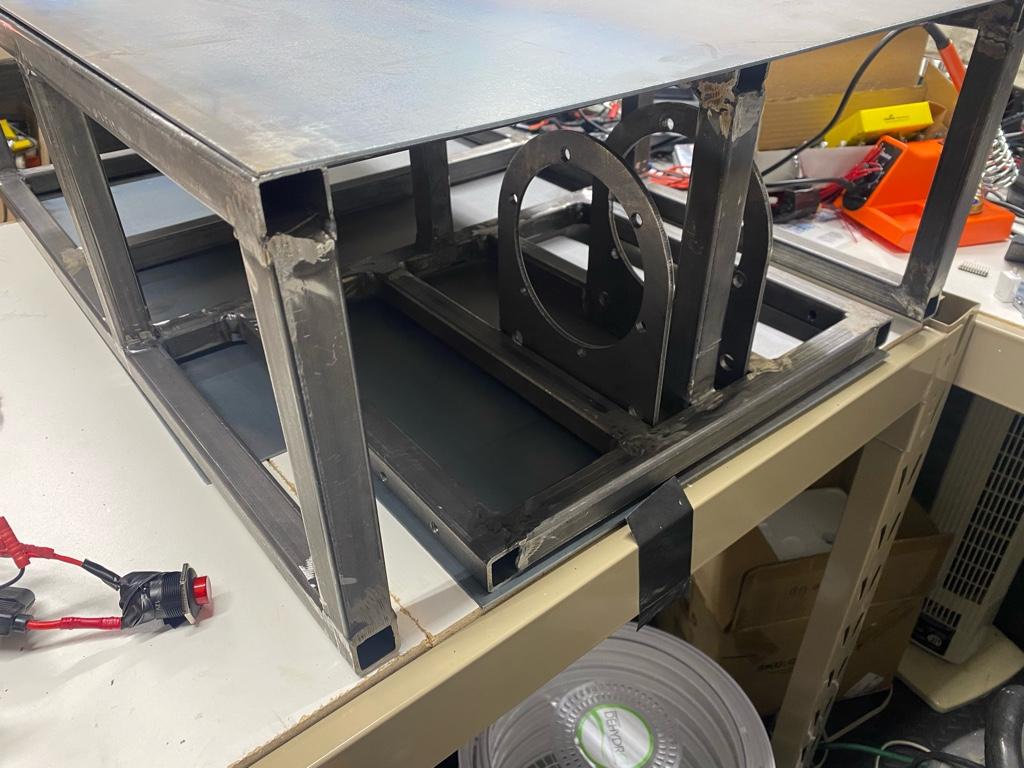

Schools out so we had trips and a family sick spell, so not much to update until today. I spent a few hours grinding all the welds down. Nice and smooth now, so I can start putting panels in and attach the motor mounts

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk