crossbreak

1 MW

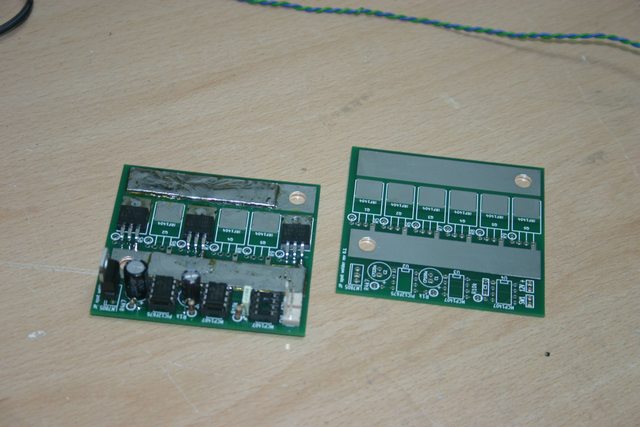

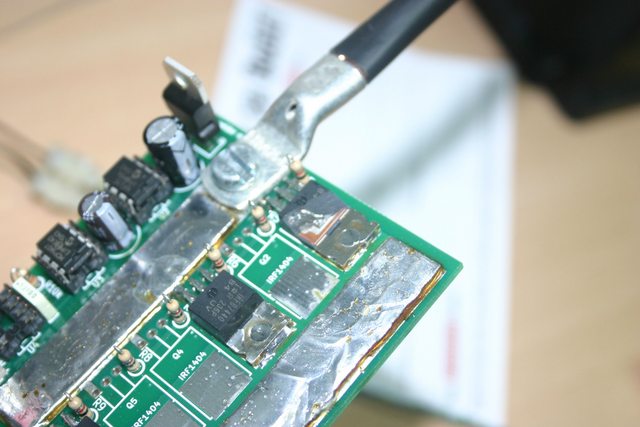

it is not a good idea to solder both wires exits to the same side like shown in this picture. The one FET closes to both source and sink will be loaded more than the others and will burn eventually.

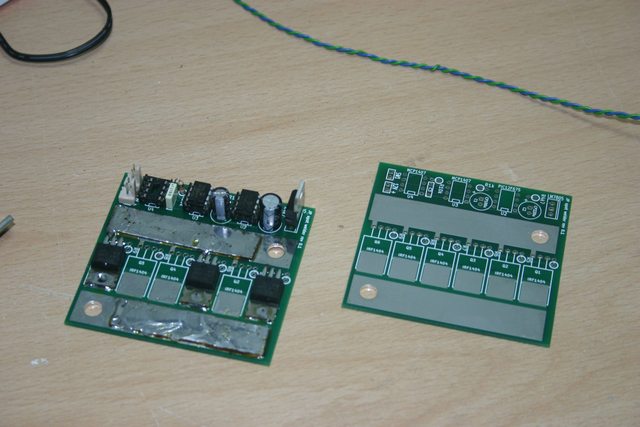

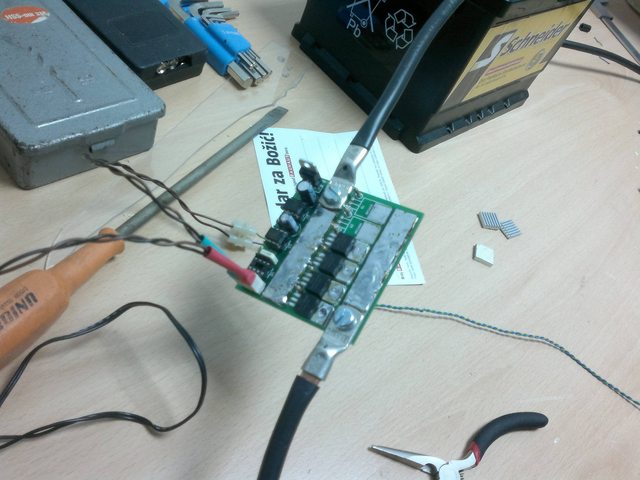

Better solder the inut to one side of the FET bank and the exit to the other like I did show on top of this thread. This way all FETs are loaded equally.

Better solder the inut to one side of the FET bank and the exit to the other like I did show on top of this thread. This way all FETs are loaded equally.