nukezero

10 kW

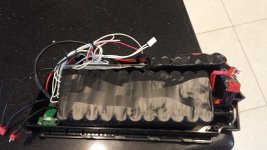

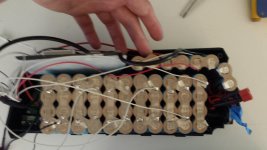

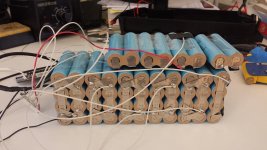

YES! Finally, I have built my FIRST ever battery pack to my liking and specifications. Wow, it was not for the faint of heart. Couple of sparks and gotchas! Solder wire touched the battery tops. No big smoke and nothing major, thank the earth.

Quickly want to mention that if you don't have any knowledge with electronics, I highly suggest you just buy a pack from lectric-cycles or em3ev! Highly, Highly! I had a few gotcha moments here and there by accident. You don't want to hook these things up on purpose and get a big poof of smoke and sparks.

I started on this project to build a hi-discharge, light-weight, cheap, SAFE, and easy-to-manage battery pack. I wanted the frame-mounted downtube packs because it's low maintenance and 10Ah is really all I need.

1. Several concerns about this battery case are:

-It requires a special BMS to use the power switch function and USB port. That is true unless you can figure out a way to route the power switch wire out of the box somehow and use that as a ignition+ to a Infineon controller. There are no other "exits" available other than the +/- terminals. You COULD punch a whole.. but yea.

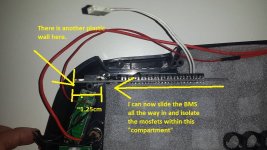

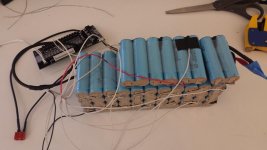

-They said No full size BMS can fit. Well, I'm here to PROVE THAT WRONG! I stuck a full size BMS in there (48v 13s Signalabs) I think this is the same BMS as pingbattery.

2. Special-thanks to voicecoil for opening up his em3ev pack because I got to see how it worked. One was to use deans plug at the discharge ports. This is useful because when you want to remove the entire pack.

3. *edit* After 50 cycles, I confirm everything is running well and decided to open up for inspection, and now hot-glued the cells together. In addition, I've heat-shrink wrapped it as well using quality wraps from batteryspace.com.

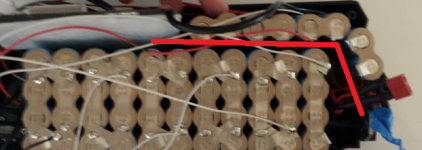

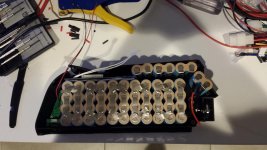

I decided to buy Samsung 18650-25R 2.5Ah cells from eBay. This is what ebikebirt and miguellart and everybody else did. The batteries arrived WITHIN A WEEK!!! Holy batman, that was SUPER fast. I paid less than $6.40/cell USD plus $88 dollar Fedex international shipping. It took 5 days. The vendor helped me tab-weld all the batteries including 1S4P and 2S1P. It's best to buy some spares too like I did.

So... now, I have the ONLY pack with the best cells that no vendor is offering yet (supposedly em3ev will be offering this in May) for a fraction of the cost.

Specs:

Samsung 18650-25R 2500mAH 48V

13S/4P = 48V nominal, 54.6V maximum

1 cell = 20Amp max discharge = 8C

Okay, enough said, here are all the pictures. ENJOY

Quickly want to mention that if you don't have any knowledge with electronics, I highly suggest you just buy a pack from lectric-cycles or em3ev! Highly, Highly! I had a few gotcha moments here and there by accident. You don't want to hook these things up on purpose and get a big poof of smoke and sparks.

I started on this project to build a hi-discharge, light-weight, cheap, SAFE, and easy-to-manage battery pack. I wanted the frame-mounted downtube packs because it's low maintenance and 10Ah is really all I need.

1. Several concerns about this battery case are:

-It requires a special BMS to use the power switch function and USB port. That is true unless you can figure out a way to route the power switch wire out of the box somehow and use that as a ignition+ to a Infineon controller. There are no other "exits" available other than the +/- terminals. You COULD punch a whole.. but yea.

-They said No full size BMS can fit. Well, I'm here to PROVE THAT WRONG! I stuck a full size BMS in there (48v 13s Signalabs) I think this is the same BMS as pingbattery.

2. Special-thanks to voicecoil for opening up his em3ev pack because I got to see how it worked. One was to use deans plug at the discharge ports. This is useful because when you want to remove the entire pack.

3. *edit* After 50 cycles, I confirm everything is running well and decided to open up for inspection, and now hot-glued the cells together. In addition, I've heat-shrink wrapped it as well using quality wraps from batteryspace.com.

I decided to buy Samsung 18650-25R 2.5Ah cells from eBay. This is what ebikebirt and miguellart and everybody else did. The batteries arrived WITHIN A WEEK!!! Holy batman, that was SUPER fast. I paid less than $6.40/cell USD plus $88 dollar Fedex international shipping. It took 5 days. The vendor helped me tab-weld all the batteries including 1S4P and 2S1P. It's best to buy some spares too like I did.

So... now, I have the ONLY pack with the best cells that no vendor is offering yet (supposedly em3ev will be offering this in May) for a fraction of the cost.

Specs:

Samsung 18650-25R 2500mAH 48V

13S/4P = 48V nominal, 54.6V maximum

1 cell = 20Amp max discharge = 8C

Okay, enough said, here are all the pictures. ENJOY

Attachments

-

battery main.JPG44.5 KB · Views: 6,413

battery main.JPG44.5 KB · Views: 6,413 -

10.jpg77.7 KB · Views: 6,412

10.jpg77.7 KB · Views: 6,412 -

8.jpg53.4 KB · Views: 6,412

8.jpg53.4 KB · Views: 6,412 -

6.jpg85.4 KB · Views: 6,412

6.jpg85.4 KB · Views: 6,412 -

5.jpg74.5 KB · Views: 6,412

5.jpg74.5 KB · Views: 6,412 -

4.jpg64.9 KB · Views: 6,412

4.jpg64.9 KB · Views: 6,412 -

3.jpg86.3 KB · Views: 6,411

3.jpg86.3 KB · Views: 6,411 -

2.jpg62.4 KB · Views: 6,412

2.jpg62.4 KB · Views: 6,412 -

1.jpg87.9 KB · Views: 6,414

1.jpg87.9 KB · Views: 6,414 -

0.jpg65 KB · Views: 6,413

0.jpg65 KB · Views: 6,413 -

13.jpg78.2 KB · Views: 6,413

13.jpg78.2 KB · Views: 6,413 -

11.jpg75.3 KB · Views: 6,413

11.jpg75.3 KB · Views: 6,413 -

wiring.jpg67 KB · Views: 5,898

wiring.jpg67 KB · Views: 5,898