That worked out well, lots of copper and no thin sections.Finally I have some sort of battery design:

It has taken forever for me to get this far

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yamaha YZ450F

- Thread starter j bjork

- Start date

j bjork

1 MW

Thanks, it was just the top one on the first picture I had to add material on.

Otherwise there would have been a thin section, the 3 cells to the left are all parallel. So especially where they meet the 4:th cell would be a weak spot.

I cant really shake off that maybe I should go 28s11p instead of 30s10p like this is..

It is nice to be able to use the same chargers as the other bike, but less controller options

Otherwise there would have been a thin section, the 3 cells to the left are all parallel. So especially where they meet the 4:th cell would be a weak spot.

I cant really shake off that maybe I should go 28s11p instead of 30s10p like this is..

It is nice to be able to use the same chargers as the other bike, but less controller options

j bjork

1 MW

Alright, so now it is pretty much no turning back as I ordered the busbars.

I asked if they could include a few extra of the small square pieces that welds to the cells, so I could do some testwelds on old cells.

But they couldent understand what I wanted, after some back and forth they asked me to send a picture.

I sent this, and got the reply "those are included" and they sent a picture of a battery pack with welded busbars.

I gave up after that

I asked if they could include a few extra of the small square pieces that welds to the cells, so I could do some testwelds on old cells.

But they couldent understand what I wanted, after some back and forth they asked me to send a picture.

I sent this, and got the reply "those are included" and they sent a picture of a battery pack with welded busbars.

I gave up after that

j bjork

1 MW

The copper plates arrived a few days ago:

About 2kg for one battey

Maybe I should have asked for 0,5mm thick, they suggested 1mm and I didnt disagree.

As I dont have any weak spots really, 0,5mm should be more than enough I think.

My weakest is 3 parallel cells have to share a 30mm wide "passage". So now it is 30mm2, in 0,5mm it would still be 15mm2.

About 2kg for one battey

Maybe I should have asked for 0,5mm thick, they suggested 1mm and I didnt disagree.

As I dont have any weak spots really, 0,5mm should be more than enough I think.

My weakest is 3 parallel cells have to share a 30mm wide "passage". So now it is 30mm2, in 0,5mm it would still be 15mm2.

harrisonpatm

10 kW

- Joined

- Aug 8, 2022

- Messages

- 836

Can you post your listing of the product you ordered? Because it probably defines the thickness of the nickel they use. And you could just order the same thickness nickel, in separate strip form, for your test welds to find your settings.Alright, so now it is pretty much no turning back as I ordered the busbars.

I asked if they could include a few extra of the small square pieces that welds to the cells, so I could do some testwelds on old cells.

But they couldent understand what I wanted, after some back and forth they asked me to send a picture.

I sent this, and got the reply "those are included" and they sent a picture of a battery pack with welded busbars.

I gave up after that

Don't feel bad, I just put 3.6kg of copper onto my battery!About 2kg for one battey

Maybe I should have asked for 0,5mm thick, they suggested 1mm and I didnt disagree.

As I dont have any weak spots really, 0,5mm should be more than enough I think.

My weakest is 3 parallel cells have to share a 30mm wide "passage". So now it is 30mm2, in 0,5mm it would still be 15mm2.

Anyway, You'll have much less resistance with the 1mm copper, that will be nice

j bjork

1 MW

Problem is that it is not nickel, I think it is nickel plated copper. And there is a slit in the middle.Can you post your listing of the product you ordered? Because it probably defines the thickness of the nickel they use. And you could just order the same thickness nickel, in separate strip form, for your test welds to find your settings.

10p of molicell p45b, so I suppose 450A, maybe I can go a little higer for my short 2sec bursts? 500 or so.What's your anticipated peak battery current?

harrisonpatm

10 kW

- Joined

- Aug 8, 2022

- Messages

- 836

Oy, that'll be tricky. Keep us postedProblem is that it is not nickel, I think it is nickel plated copper. And there is a slit in the middle.

j bjork

1 MW

Suddenly without any warning these turned up:

The tracking number I got still hasnt moved..

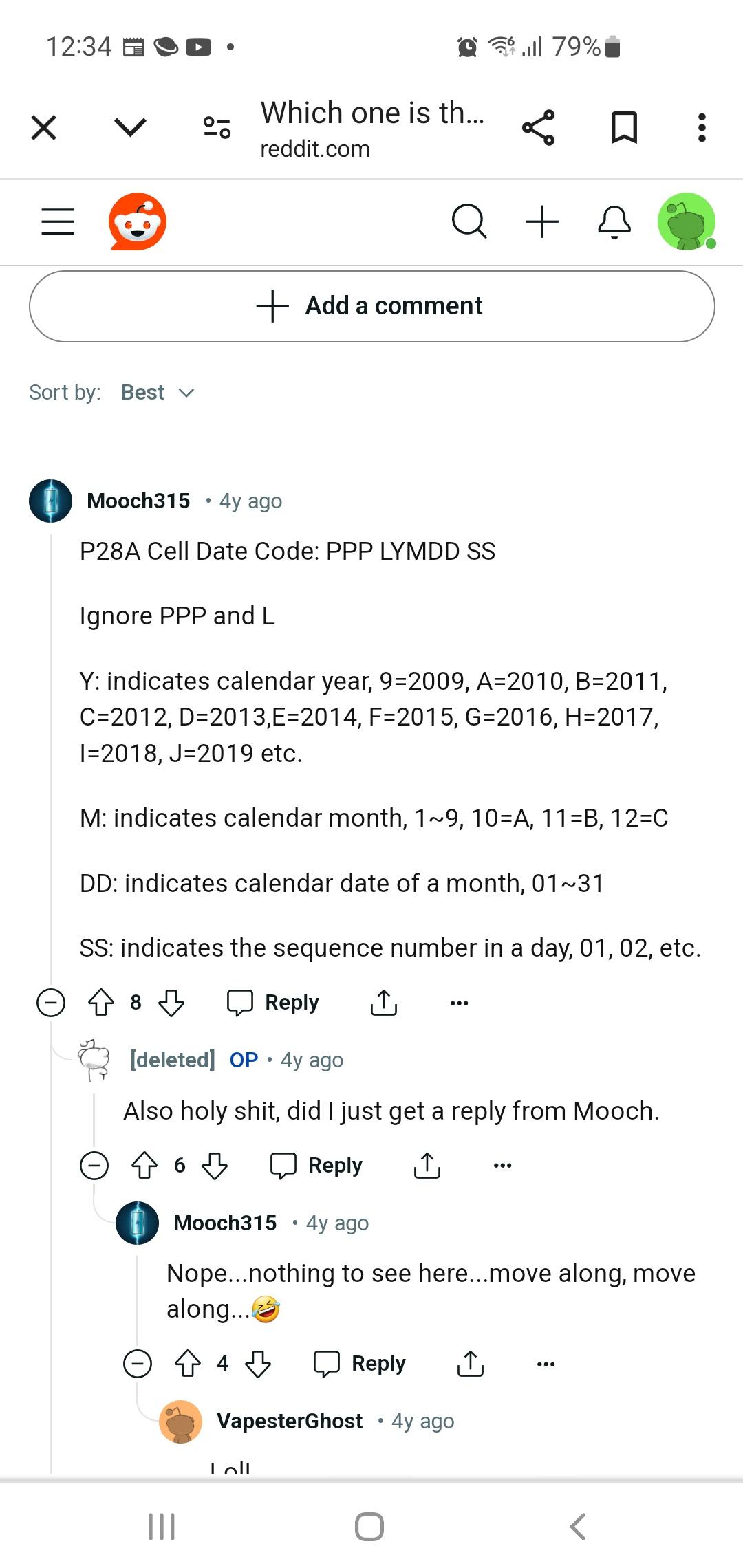

I have been chasing info about how to decipher the numbers, eventually I found this:

I suppose that means they should be manufactured 18:th January 2024?

All the cells I have looked at has the exact same numbers, not sure if that is a good or bad thing?

Under the wrap.

So, I think there are 3 possibilities here:

1: everything is fine, they are newly manufactured molicel P45B.

2: They are factory rejects, like B, C grade or something.

3: They are fake.

I think 2 are less likely as they seem to all be the same batch as they have the same numbers?

If they dont discard whole batches when they discover a problem, that might actually be kind of likely

The tracking number I got still hasnt moved..

I have been chasing info about how to decipher the numbers, eventually I found this:

I suppose that means they should be manufactured 18:th January 2024?

All the cells I have looked at has the exact same numbers, not sure if that is a good or bad thing?

Under the wrap.

So, I think there are 3 possibilities here:

1: everything is fine, they are newly manufactured molicel P45B.

2: They are factory rejects, like B, C grade or something.

3: They are fake.

I think 2 are less likely as they seem to all be the same batch as they have the same numbers?

If they dont discard whole batches when they discover a problem, that might actually be kind of likely

j bjork

1 MW

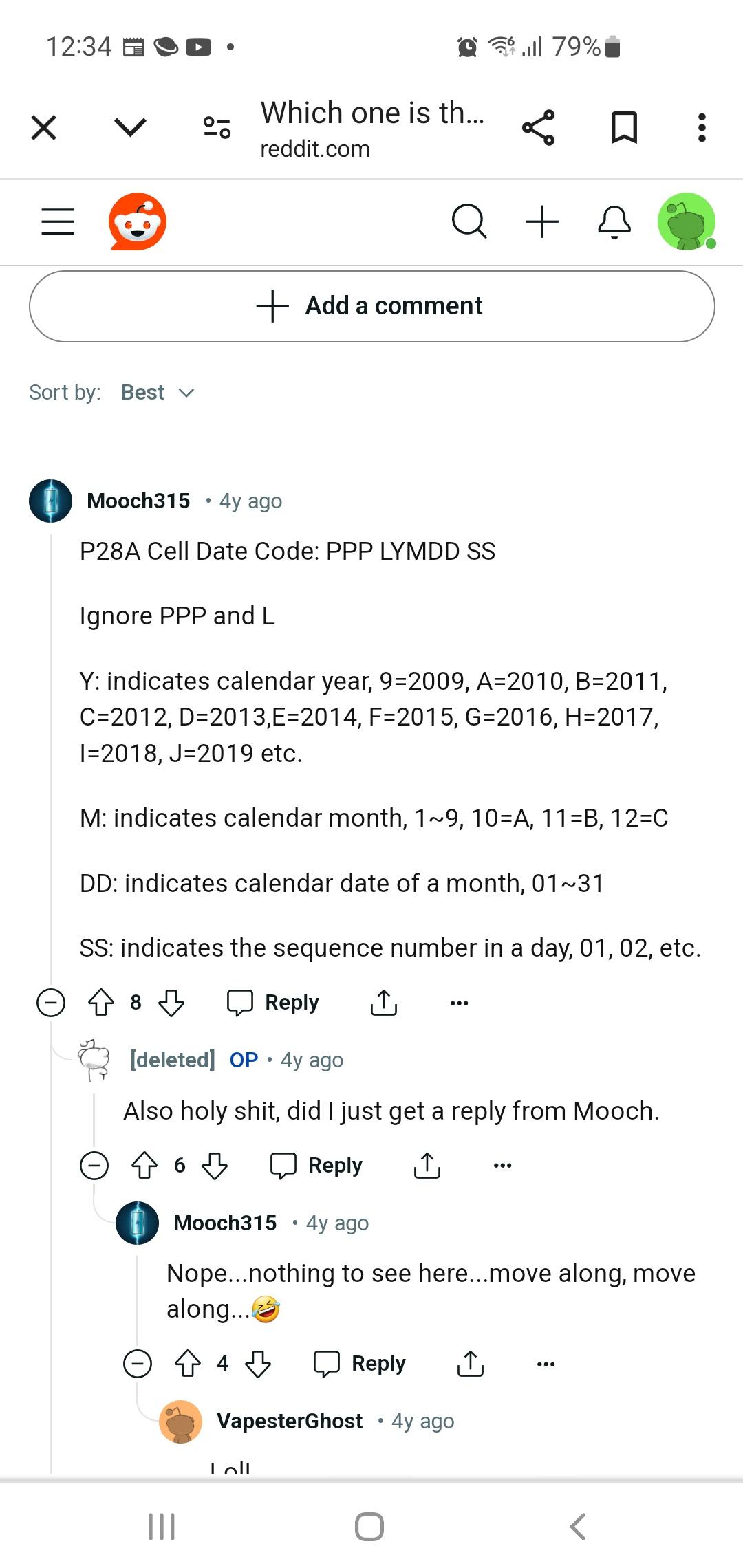

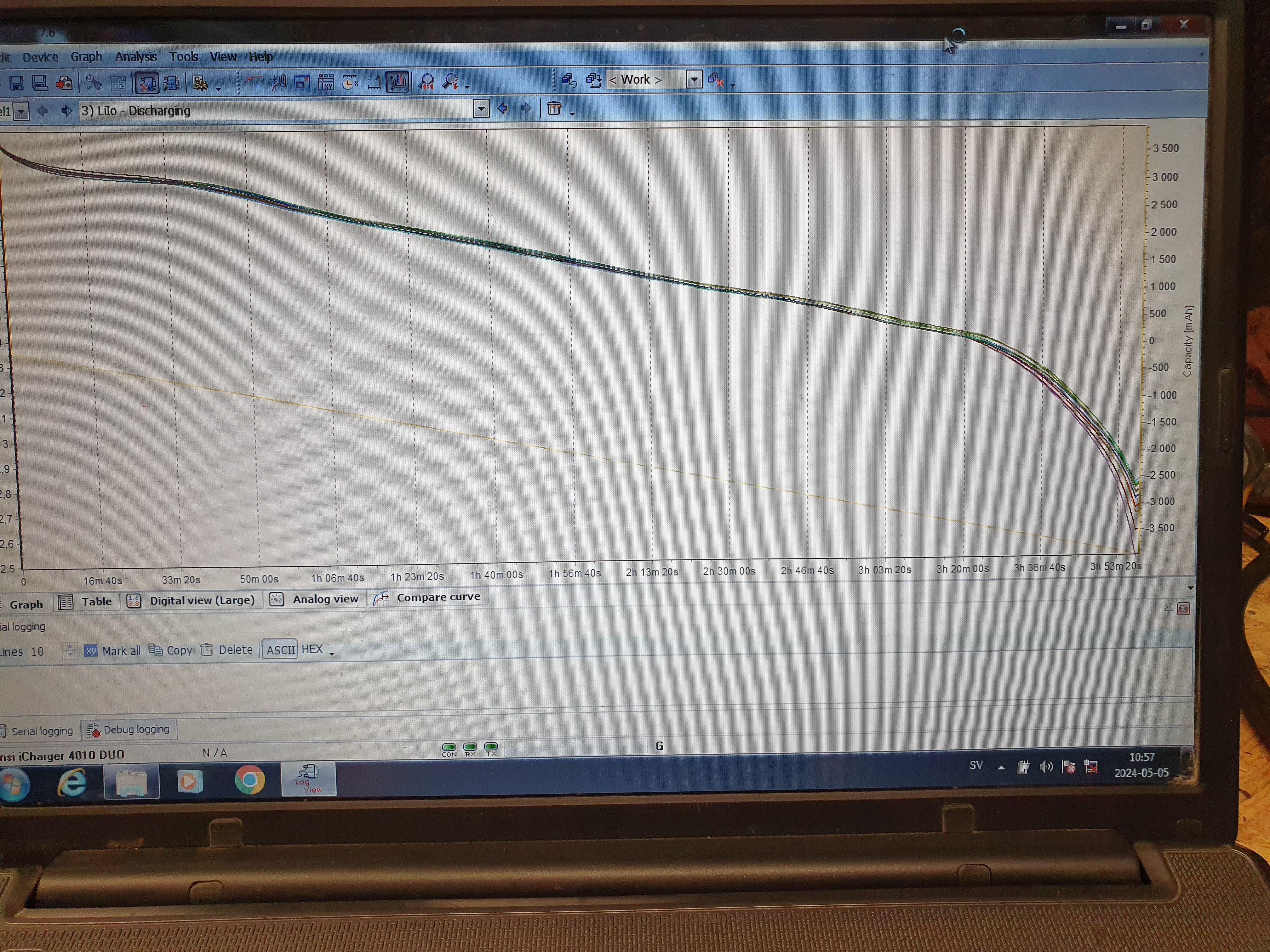

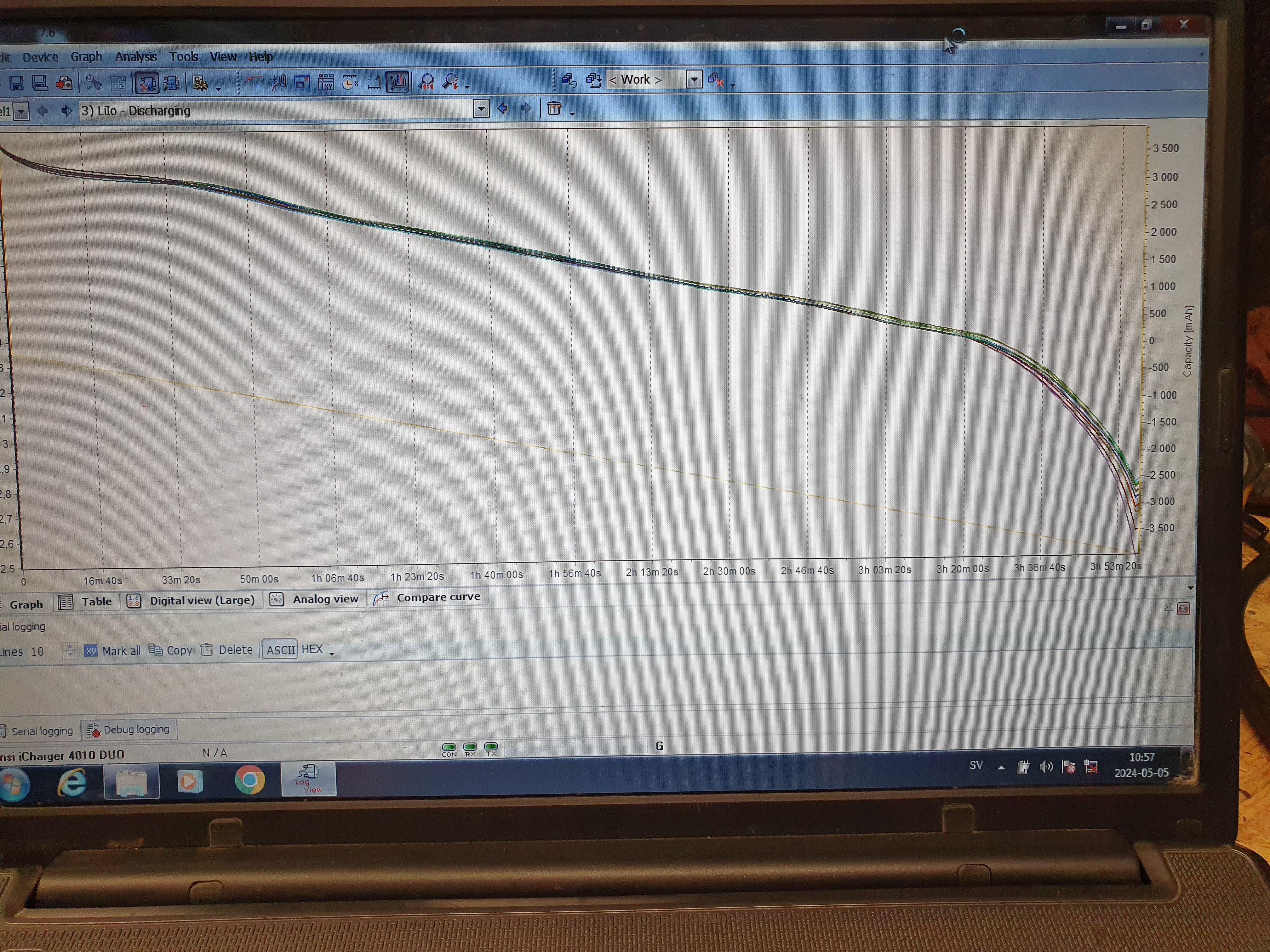

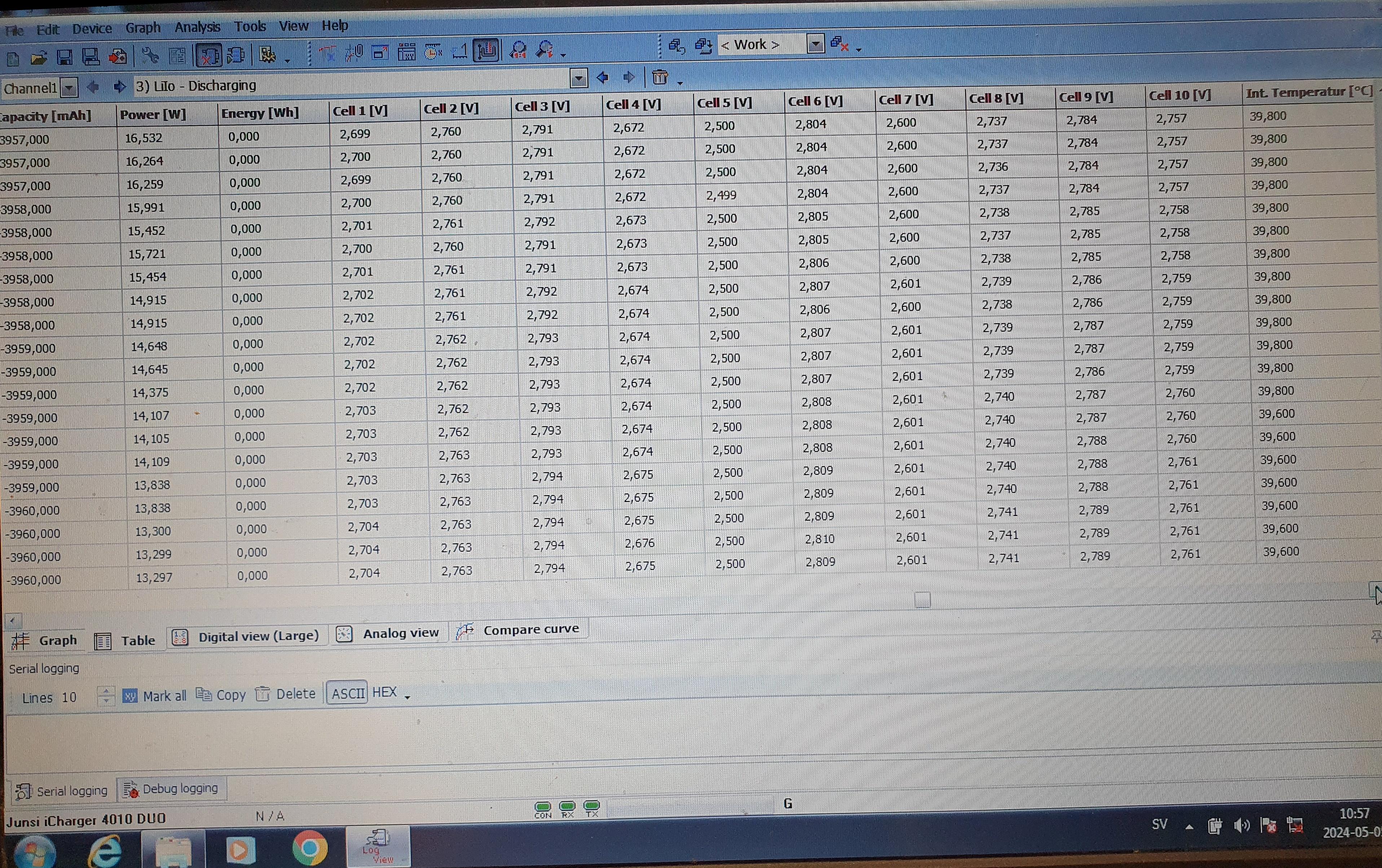

Testing batteries..

All the ones I have tried so far has ended just under 4000mah at 1A discharge.

But the test ends when one cell reach 2,5V, some cells can then be at about 2,8V.

I have seen close to 3V in one test. dont really know how much that means in mah, but I am doing a small test of the difference between the best and worst cells on the side.

I am testing 10 cells at a time, this should take about a month like this I think. I dont even want to think about testing one at a time

According to the data sheet I should be getting at least 4300mah

https://www.molicel.com/wp-content/...roduct-Data-Sheet-of-INR-21700-P45B-80109.pdf

All the ones I have tried so far has ended just under 4000mah at 1A discharge.

But the test ends when one cell reach 2,5V, some cells can then be at about 2,8V.

I have seen close to 3V in one test. dont really know how much that means in mah, but I am doing a small test of the difference between the best and worst cells on the side.

I am testing 10 cells at a time, this should take about a month like this I think. I dont even want to think about testing one at a time

According to the data sheet I should be getting at least 4300mah

https://www.molicel.com/wp-content/...roduct-Data-Sheet-of-INR-21700-P45B-80109.pdf

harrisonpatm

10 kW

- Joined

- Aug 8, 2022

- Messages

- 836

That's disappointing... you purchased these new?According to the data sheet I should be getting at least 4300mah

Especially since you're testing at 1A discharge, you should be getting the rated 4300-4500mah at such a low discharge rate.

j bjork

1 MW

Yes, they are new.

I better make a correction, all the tests have ended at just under 4000mah.

Meaning the lowest capacity cell (of 10) in each test ended there, the others would test higher.

But still, yes I think they should end over 4300mah.

I think I should get some other cells to test for reference.

I better make a correction, all the tests have ended at just under 4000mah.

Meaning the lowest capacity cell (of 10) in each test ended there, the others would test higher.

But still, yes I think they should end over 4300mah.

I think I should get some other cells to test for reference.

Dui ni shuo de dui

10 kW

That's close enough in my opinion. I'd be more focused at the internal resistance, it says a lot more about a cell health than its capacity usually.

Did you make sure the cells were fully charged before the discharge test (I think you probably did, but better check the obvious things first). Also make sure you have excellent contact between the cell and the device that measures discharge. If you are lucky enough to have a thermal imaging camera it can help you a lot to find if there's something wrong in your setup.

Did you make sure the cells were fully charged before the discharge test (I think you probably did, but better check the obvious things first). Also make sure you have excellent contact between the cell and the device that measures discharge. If you are lucky enough to have a thermal imaging camera it can help you a lot to find if there's something wrong in your setup.

j bjork

1 MW

I do a charge (to 4,2V) and discharge cycle in each test, so I think that part should be ok.

I havent made any changes to hold times or anything like that, it is definitely possible that it is just a settings problem.

Or for that matter a calibation issue.

I think at these low currents my cell holders should be enogh, at higher currents these would surely be a problem.

I realize I dont have any picture of my test rig, I will try to get that in the evening.

I will get to internal resistance soon. My charger shows a value, it has been between 20-30mOhm, but I dont trust that to be accurate. I dont have any real tester for it, I will try to just mesure voltage drop and current.

I havent made any changes to hold times or anything like that, it is definitely possible that it is just a settings problem.

Or for that matter a calibation issue.

I think at these low currents my cell holders should be enogh, at higher currents these would surely be a problem.

I realize I dont have any picture of my test rig, I will try to get that in the evening.

I will get to internal resistance soon. My charger shows a value, it has been between 20-30mOhm, but I dont trust that to be accurate. I dont have any real tester for it, I will try to just mesure voltage drop and current.

Similar threads

- Replies

- 8

- Views

- 852

- Replies

- 37

- Views

- 1,677

- Replies

- 3

- Views

- 2,308

- Replies

- 1

- Views

- 493