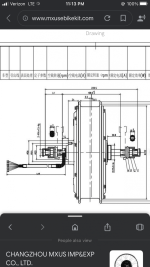

Eastwood said:Here’s the link for for the mxus I bought. I went with this seller because it was the fastest delivery. I’m supposed to receive mid April.

https://www.elecycles.com/mxus-3000w-motor-brushless-electric-bike-rear-hub-motor.html

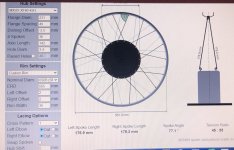

You bought the 142mm version

https://1477051759.rsc.cdn77.org/media/catalog/product/cache/926507dc7f93631a094422215b778fe0/w/x/wxt-xf40_35-45h_-mxus-3000w.jpg