titusmc

100 W

Hi everyone -

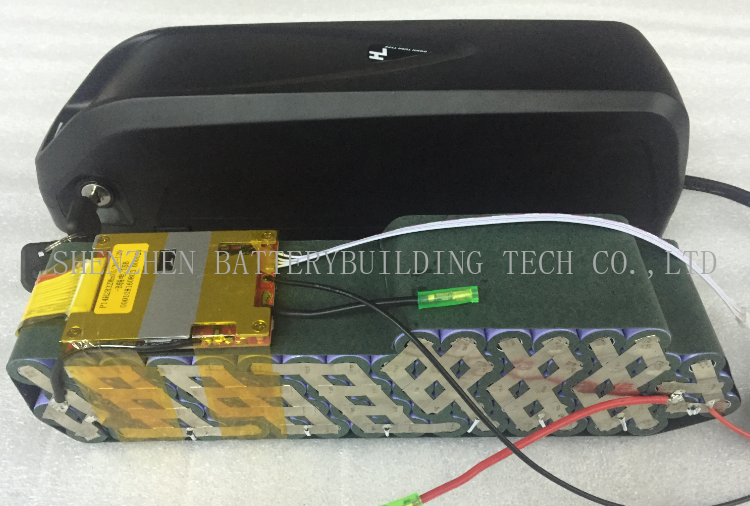

I recently bought 2 Hailong-3 cases from AliExpress and 70 cells each of Samsung 30Q and Sony VTC5A from nkon.nl. I'd like to make my own 52V (14S5P) packs with them. I have a spot welder and pure nickel strip, but I'm not quite sure what cell layout to use.

I know lunacycle has fit 70 cells into these cases somehow, but can anyone share the secret?

My goal is to use these batteries with a BBSHD, so 30A discharge.

I recently bought 2 Hailong-3 cases from AliExpress and 70 cells each of Samsung 30Q and Sony VTC5A from nkon.nl. I'd like to make my own 52V (14S5P) packs with them. I have a spot welder and pure nickel strip, but I'm not quite sure what cell layout to use.

I know lunacycle has fit 70 cells into these cases somehow, but can anyone share the secret?

My goal is to use these batteries with a BBSHD, so 30A discharge.