I'm glad he is selling just the parts as well, especially just the bare motor at a very reasonable cost if that is all you need (already got build potentials on that rattling around my head) especially with the replacement keyed motor drive shaft available as well. Looks like one could probably get the bare motor + keyed motor shaft + to your door US domestic shipping = only about $200 total or so. Not bad at all for a decent bare motor that will fit so well in a bike frame and is such low kV and has such high power potential. Probably a lot better option then trying to modify the usual 6374 or 80100 with add on hall sensors for a gear/chain/belt DIY drive.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LightningRods mid drive kit

- Thread starter spinningmagnets

- Start date

LightningRods

1 MW

Hi Guys-

Sorry I haven't been on here. Spinningmagnets was good enough to give me my own thread and then I kept posting on the old GNG thread. Force of habit, I guess.

This week my machinist delivered some beautiful jackshafts and housings to me and I've been painting, assembling and shipping them. I'm really proud of how these have turned out. They fit perfectly with the sheets and tensioners. The top end of this kit is looking really solid.

I hear all of you on price. My intention here is to offer a range of parts that you can cherry pick from as you please. I am going to offer some options like 1/2" chain secondary drive vs. the fancy 219 kart chain. Only buy what you need. There is always the option of buying a GNG and only upgrading the worst parts. The intention of the scratch built is to save customers money who would end up replacing everything on the GNG but the motor. Paying $400 for a motor is no bargain when I sell the same motor for under $200.

My 100 motors sail from Shanghai tomorrow. I'm told that crossing the Pacific to Portland will take 35 days. As soon as I get the motors I'll start pulling the helical gear motor shafts and begin machining them for our use. My plan is to offer the motors with your choice of output shaft length and diameter for $125 for the motor and $50 for annealing, machining and re-hardening the motor shaft.

I'm taking orders for complete kits now. I will be sending complete kits to Spinningmagnets and electricbike.com very soon for testing and evaluation. I can have motors air freighted to me over the next month for customers who don't want to wait. I will absorb the freight cost until I have my motors in stock.

Please write me with questions or requests. I have a number of new designs in mind based on customer requests. If I don't hear from you, I can't know what you want.

Thanks!

Mike

Sorry I haven't been on here. Spinningmagnets was good enough to give me my own thread and then I kept posting on the old GNG thread. Force of habit, I guess.

This week my machinist delivered some beautiful jackshafts and housings to me and I've been painting, assembling and shipping them. I'm really proud of how these have turned out. They fit perfectly with the sheets and tensioners. The top end of this kit is looking really solid.

I hear all of you on price. My intention here is to offer a range of parts that you can cherry pick from as you please. I am going to offer some options like 1/2" chain secondary drive vs. the fancy 219 kart chain. Only buy what you need. There is always the option of buying a GNG and only upgrading the worst parts. The intention of the scratch built is to save customers money who would end up replacing everything on the GNG but the motor. Paying $400 for a motor is no bargain when I sell the same motor for under $200.

My 100 motors sail from Shanghai tomorrow. I'm told that crossing the Pacific to Portland will take 35 days. As soon as I get the motors I'll start pulling the helical gear motor shafts and begin machining them for our use. My plan is to offer the motors with your choice of output shaft length and diameter for $125 for the motor and $50 for annealing, machining and re-hardening the motor shaft.

I'm taking orders for complete kits now. I will be sending complete kits to Spinningmagnets and electricbike.com very soon for testing and evaluation. I can have motors air freighted to me over the next month for customers who don't want to wait. I will absorb the freight cost until I have my motors in stock.

Please write me with questions or requests. I have a number of new designs in mind based on customer requests. If I don't hear from you, I can't know what you want.

Thanks!

Mike

beauty4beast

1 µW

- Joined

- Nov 23, 2013

- Messages

- 1

You are a lifesaver,  LightningRod

LightningRod

My gng bike is my only transport in the deeps of very hilly, rough tracked cornwall

Can I buy all the parts apart from the motor, and will I be able to put them with my gng motor.

So far, everything on my gng has broken, especially the bottom bracket and crank arms, although,

it has mostly happened when my 20 stone 6'5 hubby has been on it.

My gng bike is my only transport in the deeps of very hilly, rough tracked cornwall

Can I buy all the parts apart from the motor, and will I be able to put them with my gng motor.

So far, everything on my gng has broken, especially the bottom bracket and crank arms, although,

it has mostly happened when my 20 stone 6'5 hubby has been on it.

2020freerider

1 mW

beauty4beast said:You are a lifesaver,LightningRod

My gng bike is my only transport in the deeps of very hilly, rough tracked cornwall

Can I buy all the parts apart from the motor, and will I be able to put them with my gng motor.

So far, everything on my gng has broken, especially the bottom bracket and crank arms, although,

it has mostly happened when my 20 stone 6'5 hubby has been on it.

Hi Beauty4beast. Mike at Lightning Rods has provided a complete listing of available parts and pricing on his company website

http://www.lightningrodev.com/

Cheers

@ LightningRods

As for the re-machining of the motor output shafts. I'd be strongly interested in a standard 1/2" or 5/8" diameter shaft with standard american key size for that shaft size. That way lots of output sprocket options that are drop in fit for very reasonable prices. I'm thinking the motor not for mid-drive use but for single chain loop reduction left side drive builds. Motor size, power, and Kv specs make it a highly desirable option for those kind of builds as well not just mid-drives that go through the bike gearing system.

As for the re-machining of the motor output shafts. I'd be strongly interested in a standard 1/2" or 5/8" diameter shaft with standard american key size for that shaft size. That way lots of output sprocket options that are drop in fit for very reasonable prices. I'm thinking the motor not for mid-drive use but for single chain loop reduction left side drive builds. Motor size, power, and Kv specs make it a highly desirable option for those kind of builds as well not just mid-drives that go through the bike gearing system.

LightningRods

1 MW

beauty4beast said:You are a lifesaver,LightningRod

My gng bike is my only transport in the deeps of very hilly, rough tracked cornwall

Can I buy all the parts apart from the motor, and will I be able to put them with my gng motor.

So far, everything on my gng has broken, especially the bottom bracket and crank arms, although,

it has mostly happened when my 20 stone 6'5 hubby has been on it.

Hi Beauty- Yes, you can buy whatever you need a part at a time or all at once. My goal when I started out was not building a complete kit- it was to fix the GNG kit. Thing is, by the time I fixed the GNG kit I HAD built a complete kit! :lol:

I can't guarantee that the Beast to your Beauty can't break or bend my parts as well if he puts his mind and considerable mass to it. They are much stronger than the original parts however and should stand up well.

LightningRods

1 MW

turbo1889 said:@ LightningRods

As for the re-machining of the motor output shafts. I'd be strongly interested in a standard 1/2" or 5/8" diameter shaft with standard american key size for that shaft size. That way lots of output sprocket options that are drop in fit for very reasonable prices. I'm thinking the motor not for mid-drive use but for single chain loop reduction left side drive builds. Motor size, power, and Kv specs make it a highly desirable option for those kind of builds as well not just mid-drives that go through the bike gearing system.

My plan for the motor shafts is to pull and anneal them in groups of 10 so that they are ready for machining. I am organizing LightningRods to be a hot rod and custom shop for electric bikes. Each motor shaft will be hand turned on a precision lathe to the specs of the customer. The big problem I saw in the e-bike business when I dropped in was compatibility. There were shafts and sprockets and pulleys but nothing fit anything else. I will be building most of my parts to a 12mm bore standard. In the case of the motors I'll give the customer exactly what they want.

My new jackshaft design is meant to be modular. I have plans for 83mm and 100mm brackets and kits in the near future and they will need wider jackshafts to go with them. One of the advantages of 'bespoke' manufacturing from a small shop like mine is that you can get things custom tailored to your needs.

I'm working on a design that runs through the BB but stays on the right side through a single run chain. It's meant for high powered applications that are just too much for derailleur chain and sprockets. Above 3kW not only are gears for the motor not necessary for most situations, gears for the pedals are not necessary. Single run BMX chain should be the ticket.

Thanks for the reply.

I'm subscribed to this thread, would appreciate a post on it when your big sea shipment of motors shows up and you start pulling shafts.

You can expect an order from me for at least one motor with such a shaft size. Will wait until you get your big shipment in and start pulling shafts and are set up to do so. Got a couple other builds I'm working on right now that I need to finish anyway so it will be at least a month before I'm ready to start another build anyway. But I've got a spare left/right double freewheel Staton-Inc rear 48h hub laying around with a 72t #35 chain sprocket with south paw freewheel unit already on it that is just begging to be built into something. All I have to do is put a 10t #35 sprocket on one of those motors mounted in the frame triangle for single stage 7.2 reduction drive straight off the motor to the left side of the rear wheel and it should do the trick nicely for a simple no-motor-gears build and is a lot simpler and better then trying to rig up an RC type motor.

I'm subscribed to this thread, would appreciate a post on it when your big sea shipment of motors shows up and you start pulling shafts.

You can expect an order from me for at least one motor with such a shaft size. Will wait until you get your big shipment in and start pulling shafts and are set up to do so. Got a couple other builds I'm working on right now that I need to finish anyway so it will be at least a month before I'm ready to start another build anyway. But I've got a spare left/right double freewheel Staton-Inc rear 48h hub laying around with a 72t #35 chain sprocket with south paw freewheel unit already on it that is just begging to be built into something. All I have to do is put a 10t #35 sprocket on one of those motors mounted in the frame triangle for single stage 7.2 reduction drive straight off the motor to the left side of the rear wheel and it should do the trick nicely for a simple no-motor-gears build and is a lot simpler and better then trying to rig up an RC type motor.

Wishes

1 kW

LightningRods said:turbo1889 said:@ LightningRods

As for the re-machining of the motor output shafts. I'd be strongly interested in a standard 1/2" or 5/8" diameter shaft with standard american key size for that shaft size. That way lots of output sprocket options that are drop in fit for very reasonable prices. I'm thinking the motor not for mid-drive use but for single chain loop reduction left side drive builds. Motor size, power, and Kv specs make it a highly desirable option for those kind of builds as well not just mid-drives that go through the bike gearing system.

My plan for the motor shafts is to pull and anneal them in groups of 10 so that they are ready for machining. I am organizing LightningRods to be a hot rod and custom shop for electric bikes. Each motor shaft will be hand turned on a precision lathe to the specs of the customer. The big problem I saw in the e-bike business when I dropped in was compatibility. There were shafts and sprockets and pulleys but nothing fit anything else. I will be building most of my parts to a 12mm bore standard. In the case of the motors I'll give the customer exactly what they want.

My new jackshaft design is meant to be modular. I have plans for 83mm and 100mm brackets and kits in the near future and they will need wider jackshafts to go with them. One of the advantages of 'bespoke' manufacturing from a small shop like mine is that you can get things custom tailored to your needs.

I'm working on a design that runs through the BB but stays on the right side through a single run chain. It's meant for high powered applications that are just too much for derailleur chain and sprockets. Above 3kW not only are gears for the motor not necessary for most situations, gears for the pedals are not necessary. Single run BMX chain should be the ticket.

BTW, your upgrade belt drive is holding and not skipping teeth at 4kw

Wishes

PRW

100 kW

LightingRods,LightningRods said:turbo1889 said:I'm working on a design that runs through the BB but stays on the right side through a single run chain. It's meant for high powered applications that are just too much for derailleur chain and sprockets. Above 3kW not only are gears for the motor not necessary for most situations, gears for the pedals are not necessary. Single run BMX chain should be the ticket.

would you still be able to pedal - even if it is "fake" pedalling?

BTW, your upgrade belt drive is holding and not skipping teeth at 4kw

That's what the math said in the beginning, but I said it was good for 3-kW because the real numbers were just too good to be believable to someone who wasn't already familiar with these types of drives. I wanted to avoid "newbie" disappointment by going the route of "under-promise, and over-deliver".

LightningRods

1 MW

Wishes said:BTW, your upgrade belt drive is holding and not skipping teeth at 4kwNow hurry up and get that BB upgrade. I had to change out another derailleur today.

Wishes

4kW! The math said that it should work and the kart racers running 125cc gas motors through 25mm GT said it should work, but it's still great to hear a Forum member say that it works. Thanks for making my week, Wishes!

LightningRods

1 MW

PRW said:LightingRods,

would you still be able to pedal - even if it is "fake" pedalling?

Yes. It will be like 'windmilling' when you're coasting downhill faster than you can pedal. The freewheel will be ratcheting and you won't feel any pedaling resistance. But the crank will turn at the speed you choose to pedal.

"What do you mean, officer? I was pedaling at 45 mph, not running on the motor!" Don't expect me to post your bail. :lol:

Wishes

1 kW

LightningRods said:Wishes said:BTW, your upgrade belt drive is holding and not skipping teeth at 4kwNow hurry up and get that BB upgrade. I had to change out another derailleur today.

Wishes

4kW! The math said that it should work and the kart racers running 125cc gas motors through 25mm GT said it should work, but it's still great to hear a Forum member say that it works. Thanks for making my week, Wishes!

I should have specified, for those that are not aware, that was 4kw on a snow track of my bike. Dam snow won't stop falling this year so I have not had the chance to try it out with wheels on pavement. I'm sure they will offer more resistance. Still, it was dam cold, it was wet, and that track is heavy and creates significant resistance, my CA was showing 30 amps + very often while riding and the belt never slipped. So I think if it held under those conditions, I am sure it will hold with tires and pavement even if it offers slightly more resistance.

Wishes

PRW

100 kW

excellent - can't wait!LightningRods said:PRW said:LightingRods,

would you still be able to pedal - even if it is "fake" pedalling?

Yes. It will be like 'windmilling' when you're coasting downhill faster than you can pedal. The freewheel will be ratcheting and you won't feel any pedaling resistance. But the crank will turn at the speed you choose to pedal.

"What do you mean, officer? I was pedaling at 45 mph, not running on the motor!" Don't expect me to post your bail. :lol:

meelis11

100 W

Very nice, I wish it had available when I bought my kit.

I bought 2 goodyear belts, first replacement lasted 270km commuting and just broke when it was not stressed at all (30km/h commuting and pedaling)! Maybe it was defective - teeth are looking brand new and it was not worn.

Original gates belt lasted 1600km - I have read here that goodyear belt is better...

If I broke my third belt I just installed, then I probably upgrade primary side to belt.

Do I need upper sheets and GT pulley set and GT 25mm belt? Do I need anything more, can I keep original jackshaft and wreewheel?

Meelis

I bought 2 goodyear belts, first replacement lasted 270km commuting and just broke when it was not stressed at all (30km/h commuting and pedaling)! Maybe it was defective - teeth are looking brand new and it was not worn.

Original gates belt lasted 1600km - I have read here that goodyear belt is better...

If I broke my third belt I just installed, then I probably upgrade primary side to belt.

Do I need upper sheets and GT pulley set and GT 25mm belt? Do I need anything more, can I keep original jackshaft and wreewheel?

Meelis

Wishes

1 kW

meelis11 said:Very nice, I wish it had available when I bought my kit.

I bought 2 goodyear belts, first replacement lasted 270km commuting and just broke when it was not stressed at all (30km/h commuting and pedaling)! Maybe it was defective - teeth are looking brand new and it was not worn.

Original gates belt lasted 1600km - I have read here that goodyear belt is better...

If I broke my third belt I just installed, then I probably upgrade primary side to belt.

Do I need upper sheets and GT pulley set and GT 25mm belt? Do I need anything more, can I keep original jackshaft and wreewheel?

Meelis

Likely you did not get the tension right after you replaced it with the goodyear belt. Because indeed it is able to last much longer than the stock gates belt.

You need the upper adjustable plates, 2 x pulley's and the belt. All of which Lightningrod provides if you want. And yes, you can keep the existing jackshaft and freewheel, they work fine with the upper plates.

Wishes

meelis11

100 W

Wishes said:meelis11 said:Very nice, I wish it had available when I bought my kit.

I bought 2 goodyear belts, first replacement lasted 270km commuting and just broke when it was not stressed at all (30km/h commuting and pedaling)! Maybe it was defective - teeth are looking brand new and it was not worn.

Original gates belt lasted 1600km - I have read here that goodyear belt is better...

If I broke my third belt I just installed, then I probably upgrade primary side to belt.

Do I need upper sheets and GT pulley set and GT 25mm belt? Do I need anything more, can I keep original jackshaft and wreewheel?

Meelis

Likely you did not get the tension right after you replaced it with the goodyear belt. Because indeed it is able to last much longer than the stock gates belt.

You need the upper adjustable plates, 2 x pulley's and the belt. All of which Lightningrod provides if you want. And yes, you can keep the existing jackshaft and freewheel, they work fine with the upper plates.

Wishes

What is right tension, how much play it needs if i push it with finger from other side of stock tensioner? I can say that it was tensioned to be quite stiff - maybe 1mm play. Now I have it more loose, about 2-3mm play

Wishes

1 kW

meelis11 said:Wishes said:meelis11 said:Very nice, I wish it had available when I bought my kit.

I bought 2 goodyear belts, first replacement lasted 270km commuting and just broke when it was not stressed at all (30km/h commuting and pedaling)! Maybe it was defective - teeth are looking brand new and it was not worn.

Original gates belt lasted 1600km - I have read here that goodyear belt is better...

If I broke my third belt I just installed, then I probably upgrade primary side to belt.

Do I need upper sheets and GT pulley set and GT 25mm belt? Do I need anything more, can I keep original jackshaft and wreewheel?

Meelis

Likely you did not get the tension right after you replaced it with the goodyear belt. Because indeed it is able to last much longer than the stock gates belt.

You need the upper adjustable plates, 2 x pulley's and the belt. All of which Lightningrod provides if you want. And yes, you can keep the existing jackshaft and freewheel, they work fine with the upper plates.

Wishes

What is right tension, how much play it needs if i push it with finger from other side of stock tensioner? I can say that it was tensioned to be quite stiff - maybe 1mm play. Now I have it more loose, about 2-3mm play

With the narrow stock belt. As much tension as you can give it is better. The slightest loose in it and it will skip. That was my experience with it even at stock power levels. I always applied as much tension as I was able to force on it using the small tensioner that it comes with stock.

Wishes

LightningRods

1 MW

I've already posted this photo of my 25mm GT primary drive on the original GNG thread but here it is again for readers who land here first.

Gates lists proper belt tension at 1/64" per inch of center to center distance on the pulleys. Our center to center is 4.6" so the deflection in a properly tensioned belt should be .07" or 1.8mm.

Gates lists proper belt tension at 1/64" per inch of center to center distance on the pulleys. Our center to center is 4.6" so the deflection in a properly tensioned belt should be .07" or 1.8mm.

crossbreak

1 MW

Wishes said:Above 1000 watts, never shift under load.

I read somewhere a bicycle drive train can handle around 2000 watts. Above that, your stressing it. I run my gng at about 3.5kw, and it eats through chains, bends chain rings and wears out your rear cassette pretty fast.

this is somewhat true. What most people forget: The chain pull induced by the motor is always the same, it does not depend on the gear. But the engaged cassette sprocket teeth do change with the gear, since the slower ones are larger and so they can take more load.

Simple solution: Use cassette sprockets with more than 14T. Smaller ones are waste very quickly. I have ridden my BPM2 more often these days (pulls 3200W), chain an cassette do fine. I just locked the gears smaller than 14T and dont use them.

But: This does only work since I only use very low phase amps to keep chain force down, I use 60A phas and 45A battery which is a very small ratio of 1.333 . Factory setting is around 2.5. That would destroy my chain within a few hundred kilometers, since the chain always gets overstressed when pulling FT at low rpm.

BTW:If you want more than 3kW, 6kW is also possible with a derailleur chain, but you should only use sprockets with 28T+ :lol: that makes using this chain somewhat useless. I'd go for single speed in a 4kW+ bike.

Great that you did find your way to the market lightningrods

I don't really understand your sentence completely, but for singlespeed the are better chains than BMX, like #219 and #35 and #41lightningrods said:Above 3kW not only are gears for the motor not necessary for most situations, gears for the pedals are not necessary.

If you really want to pedal with high power through the gears and fast, freewheel cranks drive are useless. You should go for a "dual freewheel jackshaft drive" or (in more common words): a crossbreak style drive. It's superior to freewheel cranks in every manner http://endless-sphere.com/w/index.php/EBike_Motors_Middrive#Jackshaft_Dual_Freewheel_ConfigPRW said:LightningRods said:LightingRods,

would you still be able to pedal - even if it is "fake" pedalling?

This should be possible with the LightningRods kit as well if you have the right parts and depending on your frame. Sadly LightningRods did never try it.

With the 73mm/68mm mounting bracket, and swapping in the 100mm jackshaft...it might be possible to make a crossbreak drive quite easily. If there is excess shaft, it could be easily trimmed. I will find out soon...

LightningRods

1 MW

crossbreak said:If you really want to pedal with high power through the gears and fast, freewheel cranks drive are useless. You should go for a "dual freewheel jackshaft drive" or (in more common words): a crossbreak style drive. It's superior to freewheel cranks in every manner http://endless-sphere.com/w/index.php/EBike_Motors_Middrive#Jackshaft_Dual_Freewheel_Config

This should be possible with the LightningRods kit as well if you have the right parts and depending on your frame. Sadly LightningRods did never try it.

All I have tried to do so far is to take the concept behind the GNG mid drive and execute it properly. There are a lot of things that I don't like about even the basic layout that I plan to continue moving away from. This is only my first effort. I have plans for many different layouts.

I completely agree that it's preferable to keep motor power out of the BB when possible. On many bikes, especially FS bikes, there is just so little room inside the frame or between the BB and rear wheel. Sometimes the BB freewheel drive is the tidiest package.

'Universal' kits are a problem. "One size fits all" never really works. For instance I want to use cast 2 piece urethane blocks to grab the bike frame rather than something ghetto like a hose clamp. There is so much variation in frame diameters and profiles now that I can't just offer one or two sizes of pre cast split block. I keep trying to think of a simple system for bike owners to cast the urethane blocks themselves using my steel parts and then casting the 2 part urethane right on their frame.

I'll look into the Crossbreak jackshaft. I have to admit that I have gotten so wrapped up in my own work and corresponding with people from E-S that I don't take the time to get out and cruise the Forum like I used to. I'll get back to it. Thanks for the suggestions.

LightningRods

1 MW

I went to the Portland Roadster Show last night. There was a guy there with an incredible display of racing karts. His 28 horsepower, 12,000 rpm, 100 mph racing kart uses #219 final drive. He uses DID, the same brand of chain that I use, and said that he has never broken a chain.

crossbreak

1 MW

yep, they are great stuff and payable.

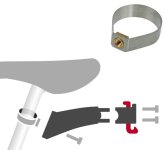

I like hose clamps, if you hide the lock and cover them with heatshrink they dont look too ghetto.

BTW there are similar things like hoseclamps use a lot with "KlickFix extender" mount systems and sidestands. Not called hosclamp, more stable, ultimately versatile. I dont know what they are called.

I like hose clamps, if you hide the lock and cover them with heatshrink they dont look too ghetto.

BTW there are similar things like hoseclamps use a lot with "KlickFix extender" mount systems and sidestands. Not called hosclamp, more stable, ultimately versatile. I dont know what they are called.

Attachments

Similar threads

- Replies

- 1

- Views

- 600

- Replies

- 3

- Views

- 1,014

- Replies

- 25

- Views

- 3,100

- Replies

- 11

- Views

- 1,181