LightningRods

1 MW

I'll be working on making premium driveline parts available a la carte this year. The difficult part is that I have them made in the US so they're not going to be China cheap. So far the Chinese are still focused on being crap merchants and moving a lot of low end product at the lowest possible price. They're really forcing everyone else to make better quality parts and to be satisfied with a smaller market share. A case in point would be a White Industries freewheel vs. a Dicta freewheel.

I do have solid freewheel delete hubs available. The ones I've made so far have been made of 6061 aluminum and have a 12mm bore. Boring these out to 15mm will be simple. If people feel that they need T303 stainless steel I can have my machinist make a run of them.

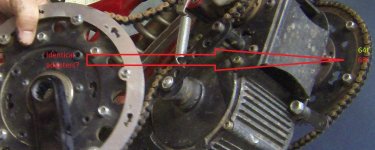

Stonezone tried the solid hub on his big block and decided to go back to a freewheel. When installed on the large pulley or sprocket of the primary drive that freewheel allows pedaling without cogging the motor. If you ride your mid drive like a motorcycle and never pedal without motor it might be the ticket for you.

I do have solid freewheel delete hubs available. The ones I've made so far have been made of 6061 aluminum and have a 12mm bore. Boring these out to 15mm will be simple. If people feel that they need T303 stainless steel I can have my machinist make a run of them.

Stonezone tried the solid hub on his big block and decided to go back to a freewheel. When installed on the large pulley or sprocket of the primary drive that freewheel allows pedaling without cogging the motor. If you ride your mid drive like a motorcycle and never pedal without motor it might be the ticket for you.