OK... update time!

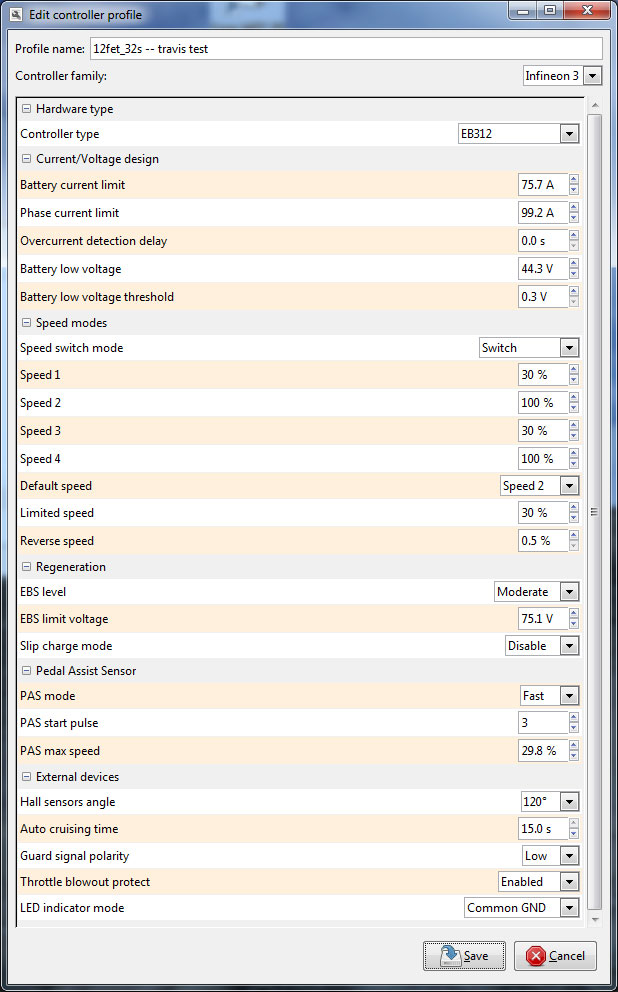

so first thing I did from the post above, was test out the motor and find my hall combos:

once I had that setup, I knew my motor controller worked with my motor and halls..

I still have a little to-do here.. The wires for the halls inside the motor kept moving into the way of the can bearing. so I used some superglue to tack them in place.. I need to re-open the motor and use the proper high temp silicone adhesive to hold them in place. I also found that the can of the motor is slipping on the shaft. I need to pin that down for sure. I'll get back to this later.

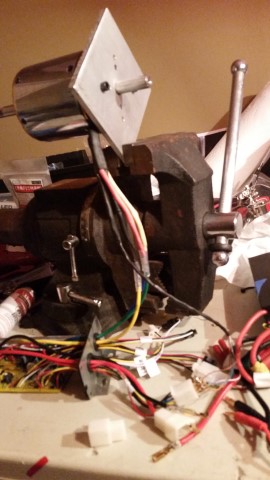

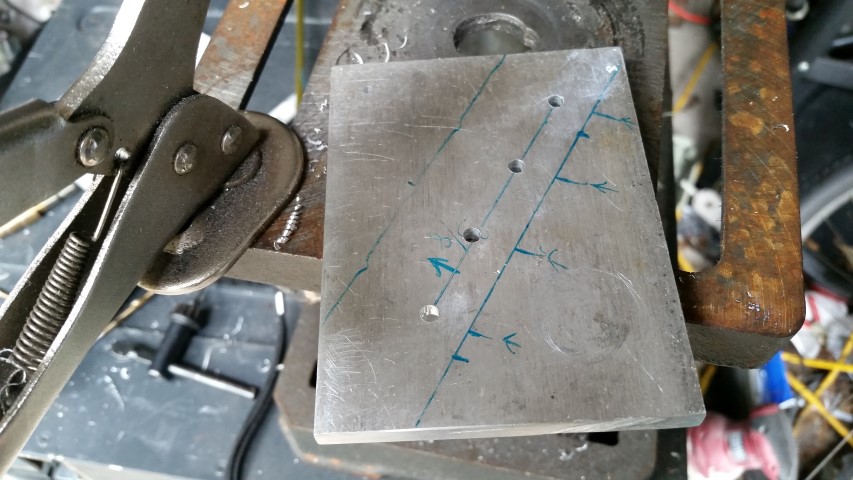

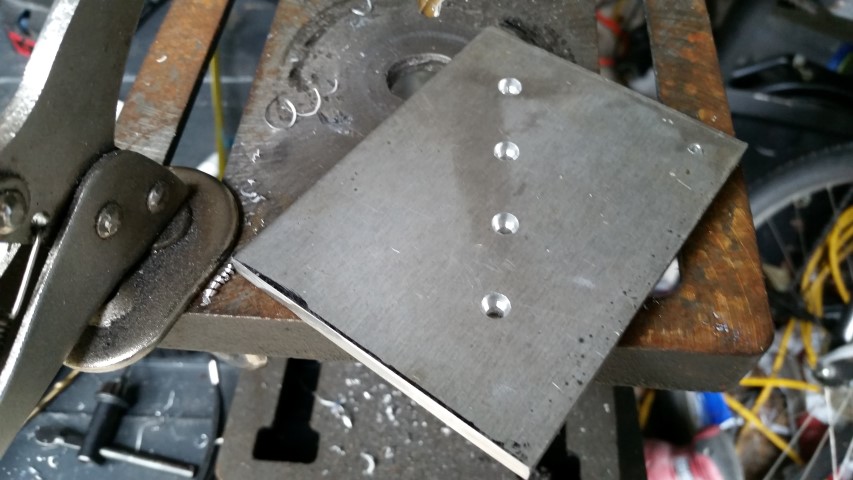

I dragged out my tabletop drill press and made the holes for the plate you see above... I then measured out and drilled the holes to mount the motor to the can. I decided to do a 3 bolt mount. I wish I took more pics, but I was working on it and didnt think about it at first. How I did it was simple..

After figuring out where the bolt holes needed to be, I drilled them out.

I took the proper size nuts, and "spun" them on the belt sander.. this takes the cad plating off the side of the nuts, exposing clean metal for welding and makes them nice and round.

I then tightened the nuts to the plate.

I put the plate up in place.. the nuts are now touching the frame tube. with a little filing,everything just clears with a very light, by hand press fit.

At this point I mark out the tube where I want to cut and keep.

where the cut marks meet, I drill holes, so they have curves in the corners instead of sharp points.

I chop the extra metal out of the tube... the top motor side cut is a little strange, but it had to match the fender/chaincover I will be using. all the other cuts are uncovered, so they are nice and straight.

With the tube cut, theres access to see where the nuts meet the tube. tack the nuts to the tube, and unscrew the plate.

finish up the weld around them and you're good.

Then go back and clearance the inside of the nuts to clear the motor if needed.. i only needed a couple swipes of the file in one spot and it all cleared nicely.

I then took the mount plate, and used the belt sander a bit to make sure there were no sharp edges near where the wires were...

then bolt the whole thing back together, and use a little flap wheel so the edges of the plate match the tube.

The lower rear corner was left alone, as it will eventually have my chain slack device there.

Pics of the mount:

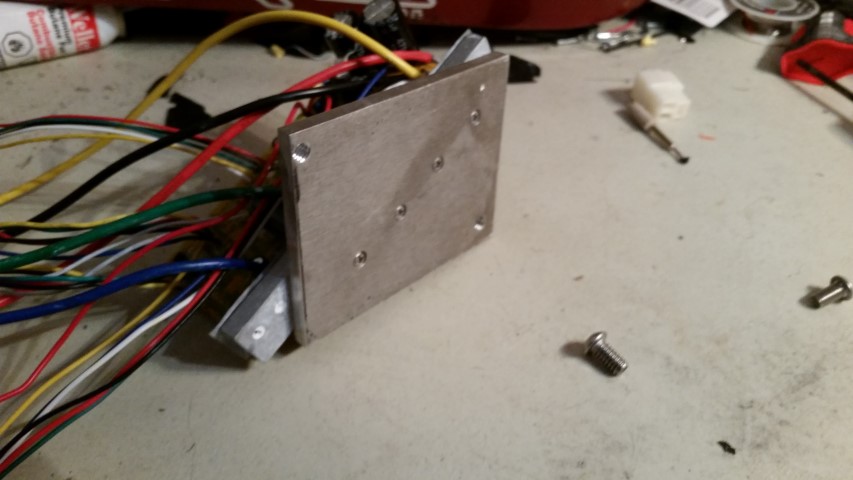

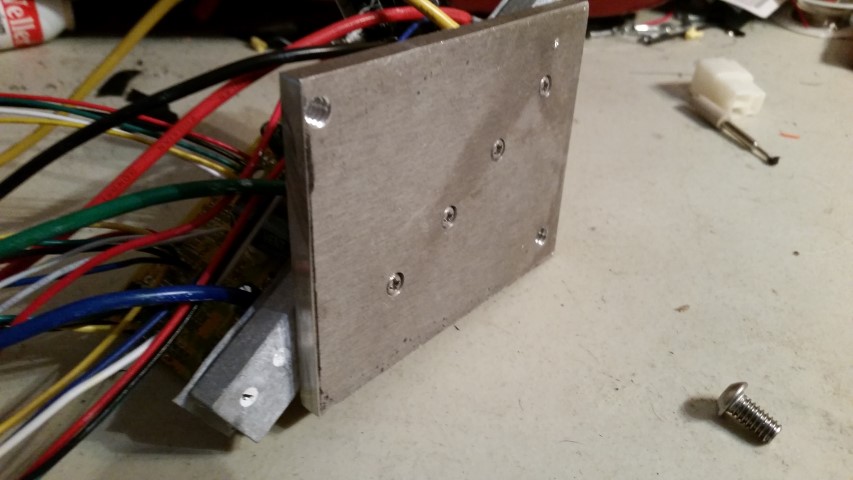

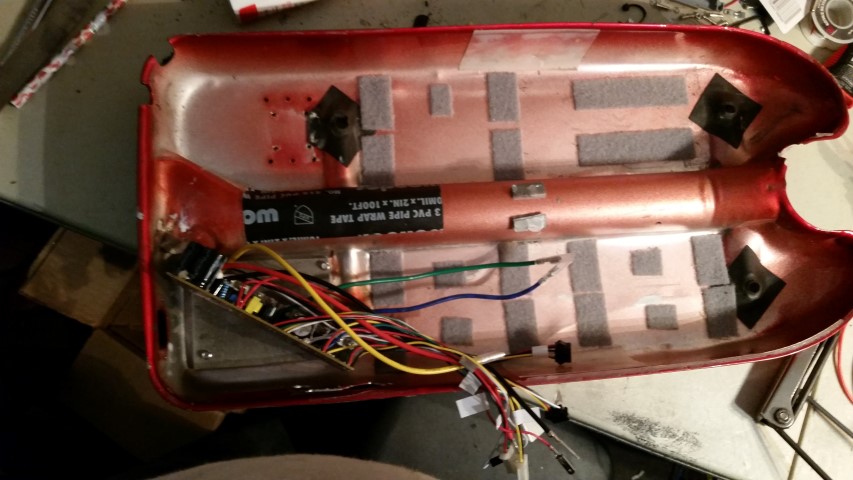

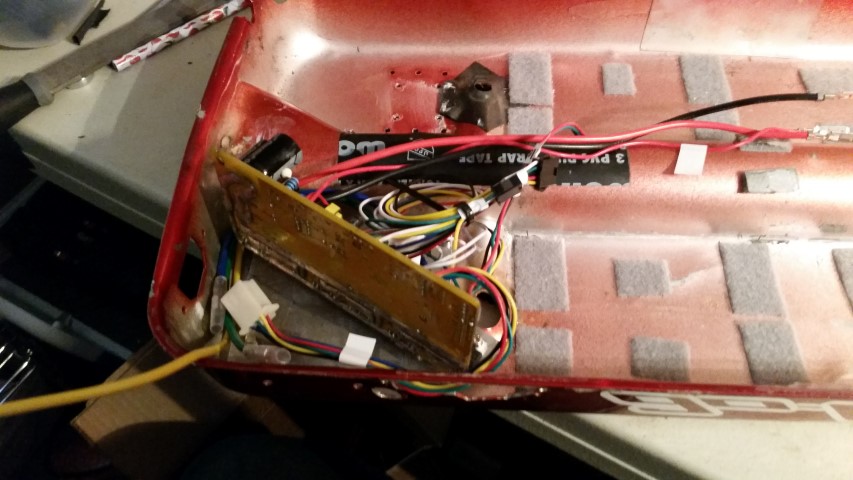

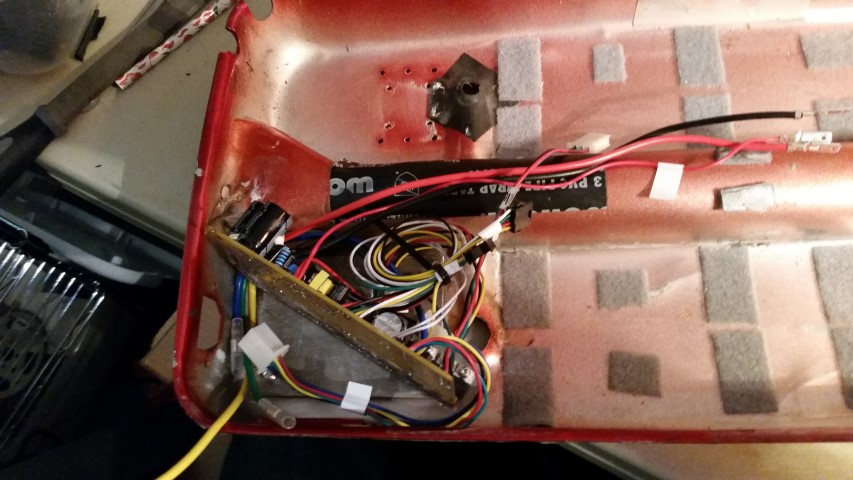

ok, with that done, I went on to the controller mounting.

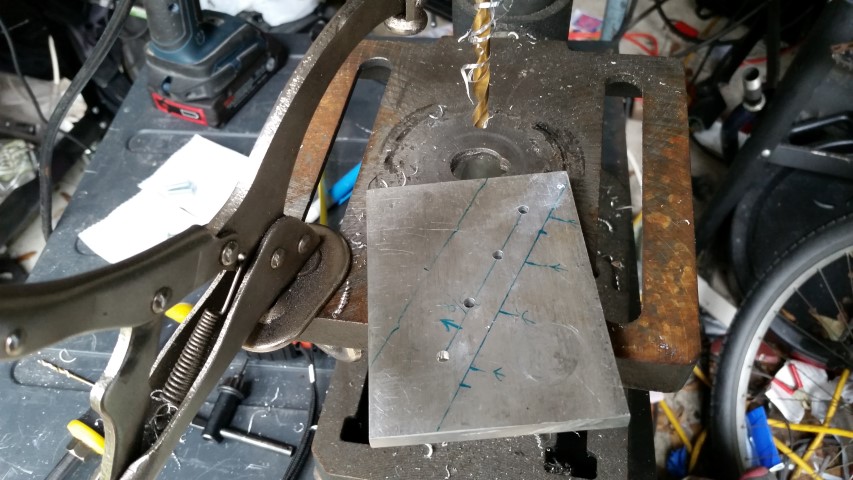

I marked out where my holes needed to be.

Then I flipped it over, and countersunk the heads

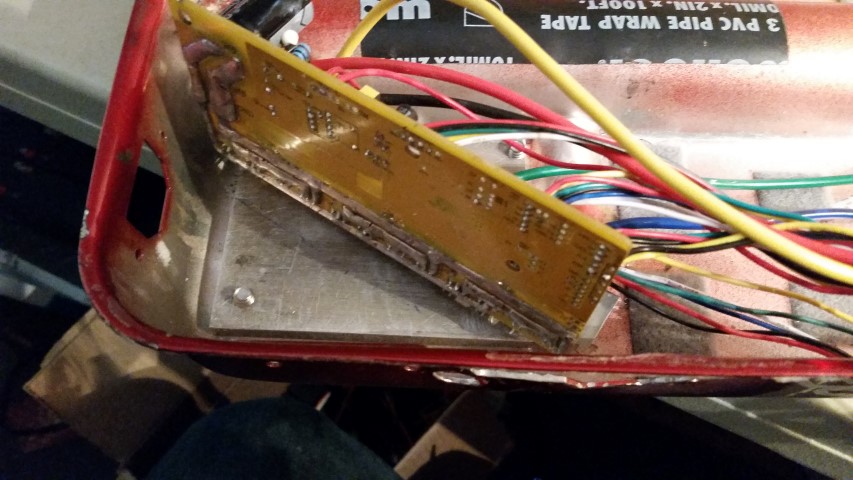

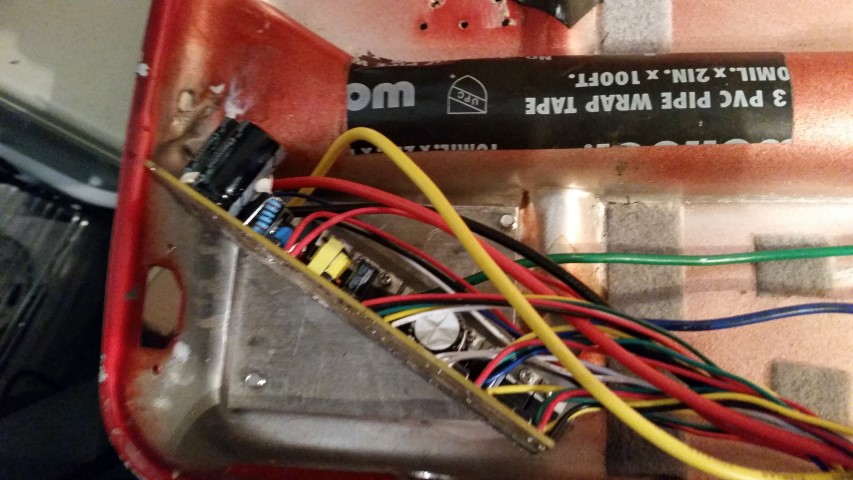

I then tapped the mounting holes for the plate... and installed the controller to it:

And then I screwed the plate to the pan with button head screws... all this will have heatsink paste on it when its on final assembly

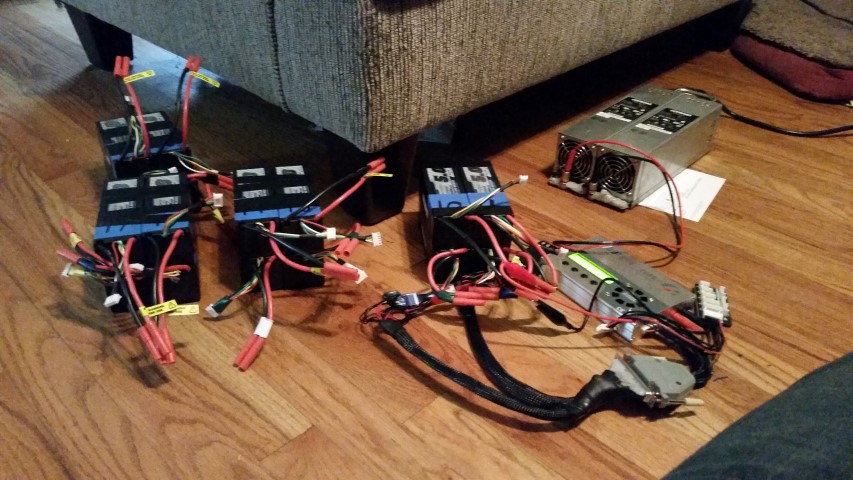

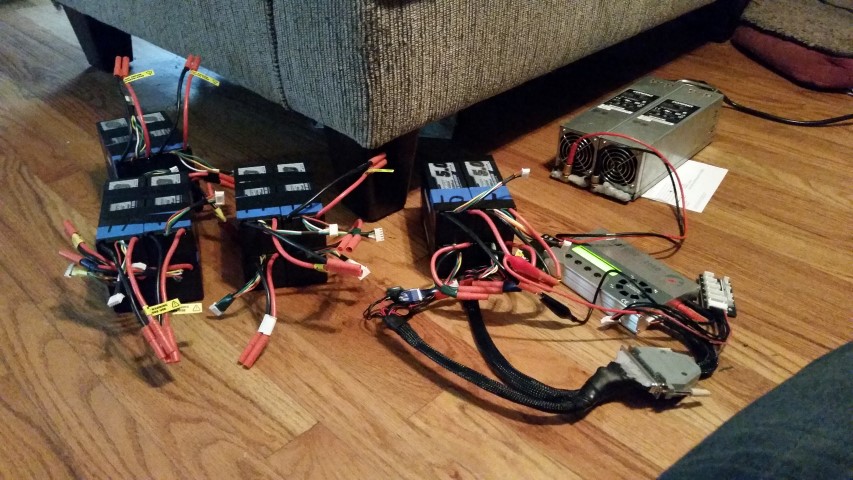

so last but not least... I charged up all 4 16s packs... 8 cells at a time. that way they could all be the same voltage when I paralleled them.

In these pics, we have two server powers supplies connected for 24 volts (24v @ 32 amp capable nice supplies.)

They're powering a 208b i charger.. where its charging each 5Ah 8s pair at a solid 1c rate of 5 amps.

for those wondering about lipo safety.. notice my jeans/leg in the corner. I am sitting next to this the entire time as it charges.... tv is on, but I am reminded... server power supply fans are LOUD!

While this is charging, I made the balance charger harness ending in two 8s connectors and the main power harness.

so heres where I am at now...I need to:

1. finish the main power harness

2. change connectors on the controller.

3. add connectors to the motor.

4. tighten motor bell and secure internal wires in motor.

5. dry assemble everything... including the sprocket. It may need to be pinned on the shaft.

I think I can test ride it at this point.... but still have lots to do. have to weld the hook so I can fold it. I have to do the charger, the backpack lights, clean up all the welds for powdercoat, have it powdercoated, get a bothy fork, etc... oh and I probably will add a cycle analyst, so I need to get one of them and wire that in too... just lots and lots to do. getting there, slowly.

.