Greetings,

I'm new here and I wanted to discuss my exact setup. Also my potential setup with the new motor and controller I ordered. This is my second build.

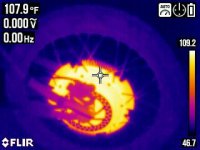

I started with 14s lipo on a 1000w 48 volt 26in direct drive hub motor setup. The controller that came with the kit I'm assuming was a 1000 watt controller. I did a shunt mod. I had to remove some of the solder because the controller kept cutting out. But I found a happy medium. I have an amp meter in line between the battery and controller. I upgraded the controller to a 2000 Watt and did a shunt mod on that. I went from 14s to 20s lipo. Now running 84 volts. With the current controller, motor and battery setup the system regularly draws a maximum of 42 amps. I did some math on that...3,528w.... Maximum speed 43 miles per hour. So this motor is taking an additional 2,500 Watts without failing. That's a neat trick. It gets warm but never hot to the touch. I just ordered a 2,500 watt controller and a 1500 watt 48 volt motor. The torque specs on the original motor was 27NM. Maximum rotating speed 460 RPM. The new motor is 55 NM and 500 RPM. I'm looking to hit 50 mph with the new motor and controller. From my understanding the motor decides the amount of current it pulls from the battery and controller. As long as the controller can handle the volts and the amps the motor will draw whatever it wants. I am very pleased with my current setup but I need to achieve 40 mph as a cruising speed due to the roads in my area. My current cruising speed is around 30 mph. I can climb steep grades at 16 to 17 miles an hour. While my current setup was good it's not enough for me. I guess my only question is am I crazy for trying to run something like this? Allowing the motor to take triple The watts and almost twice the voltage? I do not feel like my current motor is at risk for burning up. I just disassembled it yesterday and it shows no signs of damage. Is this common practice in the e-bike community? As far as over-volting and overcurrent is concerned? I would like to upgrade to a 3000 w fat tire setup, but my financial limitations only allowed me to take this middle step with the 1500 watt 48 volt motor. I have purchased a motor from this company on my first build and did the same thing with overvolting and upgrading the controller and had no issues. The reason I'm upgrading my current setup is mainly the lack of torque. Wind drag and hills prevent me from reaching my desired necessary cruising speed. My one way distance commute is 1.7 MI. So I'm not really looking to run long and hard on the motor, just quick and fast to get me there in traffic without having to ride on the side of the road or on the sidewalk. Although the speed of it is 40 mph people regularly speed. I just need to be able to keep up with traffic. This stretch of road though is only a third of my total commute. And is at the beginning so I'm always freshly fully charged. I'm curious to see how many amps this 1500 watt motor will draw with the 2500 watt controller. I'm actually surprised that the 2000 watt controller that I have now has not fried considering it's pushing almost 4,000 watts out regularly. Side note. When I opened up my new 2000 watt controller for the first time to do a shunt mod there was already solder applied to the shunts. Not really sure what that's about. But I added more anyways and was happy with the results. So yeah I just wanted to talk about my build and ask a couple questions because none of my family or my job or my girlfriend understands anything about this type of stuff and I've got no one to talk to about it LOL.

I'm new here and I wanted to discuss my exact setup. Also my potential setup with the new motor and controller I ordered. This is my second build.

I started with 14s lipo on a 1000w 48 volt 26in direct drive hub motor setup. The controller that came with the kit I'm assuming was a 1000 watt controller. I did a shunt mod. I had to remove some of the solder because the controller kept cutting out. But I found a happy medium. I have an amp meter in line between the battery and controller. I upgraded the controller to a 2000 Watt and did a shunt mod on that. I went from 14s to 20s lipo. Now running 84 volts. With the current controller, motor and battery setup the system regularly draws a maximum of 42 amps. I did some math on that...3,528w.... Maximum speed 43 miles per hour. So this motor is taking an additional 2,500 Watts without failing. That's a neat trick. It gets warm but never hot to the touch. I just ordered a 2,500 watt controller and a 1500 watt 48 volt motor. The torque specs on the original motor was 27NM. Maximum rotating speed 460 RPM. The new motor is 55 NM and 500 RPM. I'm looking to hit 50 mph with the new motor and controller. From my understanding the motor decides the amount of current it pulls from the battery and controller. As long as the controller can handle the volts and the amps the motor will draw whatever it wants. I am very pleased with my current setup but I need to achieve 40 mph as a cruising speed due to the roads in my area. My current cruising speed is around 30 mph. I can climb steep grades at 16 to 17 miles an hour. While my current setup was good it's not enough for me. I guess my only question is am I crazy for trying to run something like this? Allowing the motor to take triple The watts and almost twice the voltage? I do not feel like my current motor is at risk for burning up. I just disassembled it yesterday and it shows no signs of damage. Is this common practice in the e-bike community? As far as over-volting and overcurrent is concerned? I would like to upgrade to a 3000 w fat tire setup, but my financial limitations only allowed me to take this middle step with the 1500 watt 48 volt motor. I have purchased a motor from this company on my first build and did the same thing with overvolting and upgrading the controller and had no issues. The reason I'm upgrading my current setup is mainly the lack of torque. Wind drag and hills prevent me from reaching my desired necessary cruising speed. My one way distance commute is 1.7 MI. So I'm not really looking to run long and hard on the motor, just quick and fast to get me there in traffic without having to ride on the side of the road or on the sidewalk. Although the speed of it is 40 mph people regularly speed. I just need to be able to keep up with traffic. This stretch of road though is only a third of my total commute. And is at the beginning so I'm always freshly fully charged. I'm curious to see how many amps this 1500 watt motor will draw with the 2500 watt controller. I'm actually surprised that the 2000 watt controller that I have now has not fried considering it's pushing almost 4,000 watts out regularly. Side note. When I opened up my new 2000 watt controller for the first time to do a shunt mod there was already solder applied to the shunts. Not really sure what that's about. But I added more anyways and was happy with the results. So yeah I just wanted to talk about my build and ask a couple questions because none of my family or my job or my girlfriend understands anything about this type of stuff and I've got no one to talk to about it LOL.