Okay, so a friend of a friend kindly offered to waterjet cut my motor mount for me. How could I refuse?

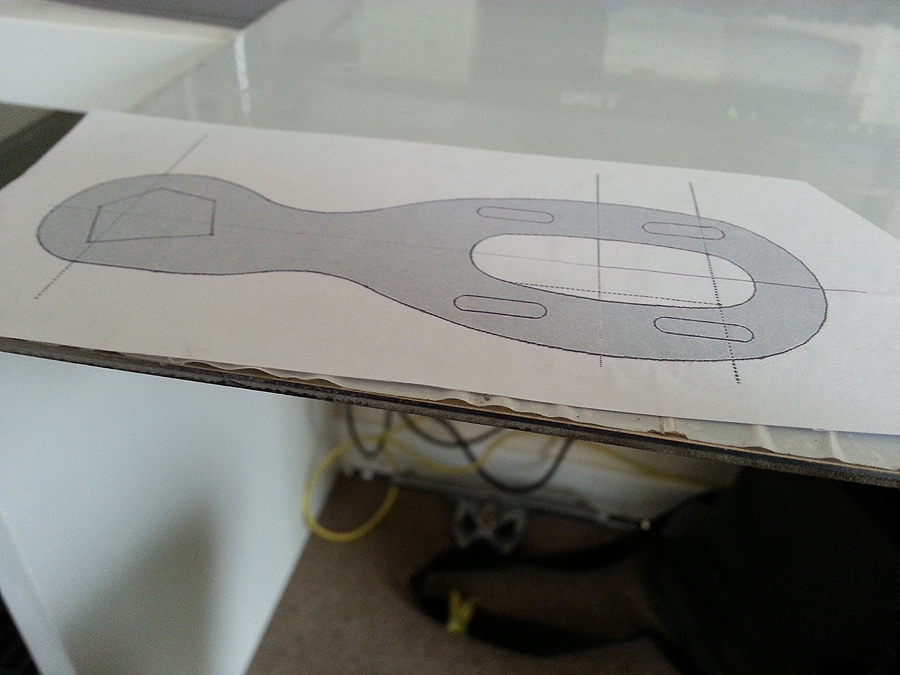

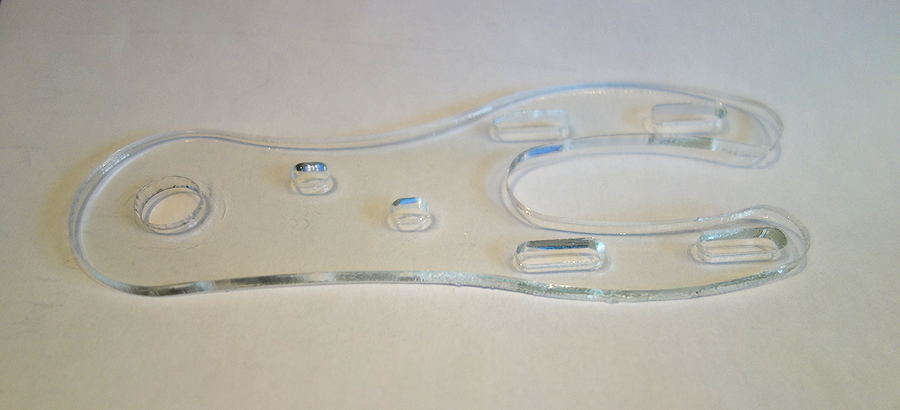

To check that the design fits the truck and motor within tolerances I mocked up the motor mount in acrylic using our laser cutter:

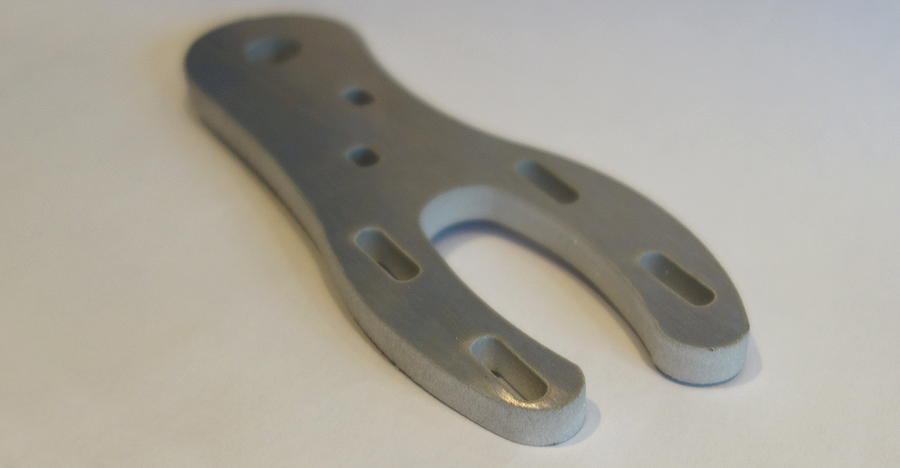

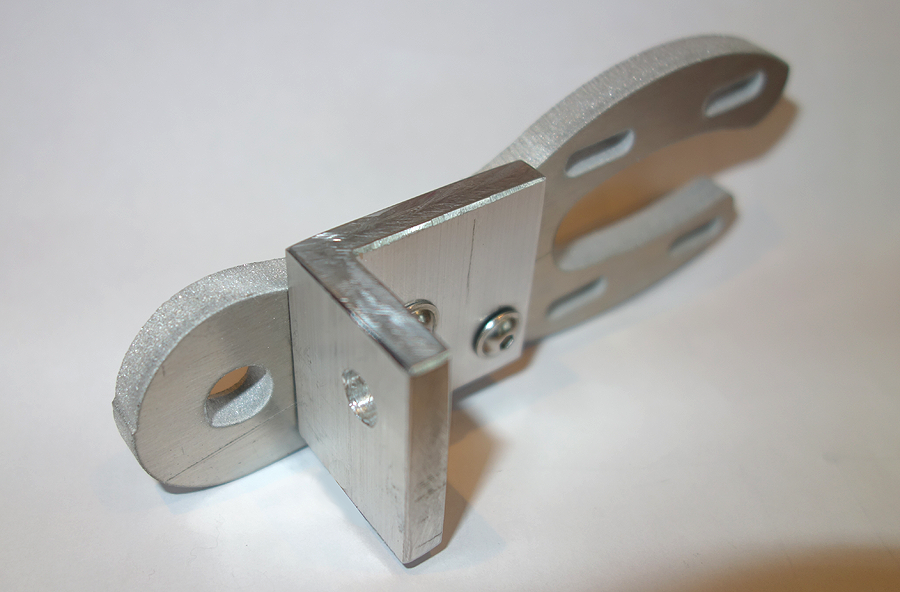

Everything looked fine so I sent over the .dxf file to the waterjet cutter. A couple of days later I had this:

He cut this as a test piece out of ~6.4mm aluminium. The final bracket will be cut from 8mm. The finished edges are a rough texture which I didn't expect. On the final piece either I or he will sand them smooth. More importantly it is very strong and fits perfectly.

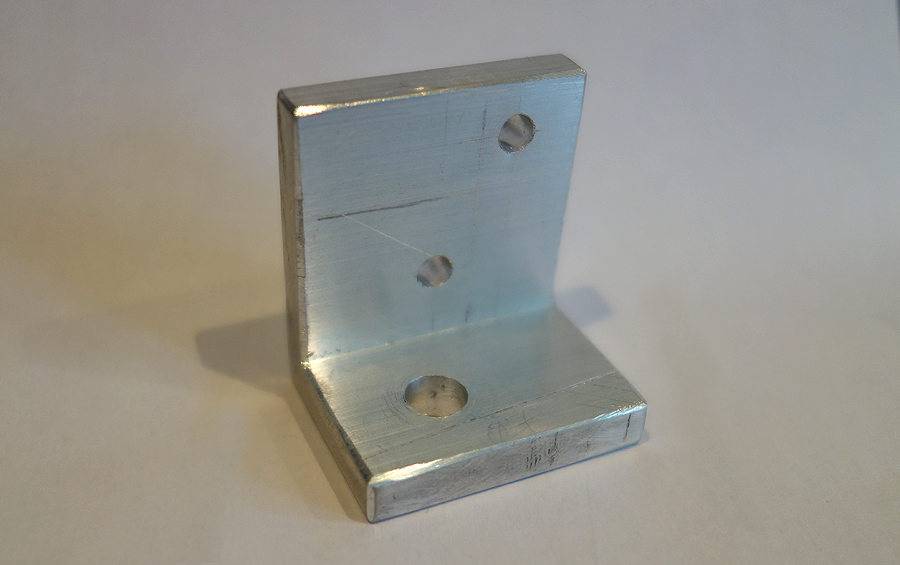

This is the second part of the bracket - Aluminium angle manually cut and drilled to utilise the brake mounting hole on the MBS Vector trucks.

M4 screws with nylon nuts hold the two pieces together. The slots in the motor mount allow the angled piece to be secured tightly onto the truck.

The axle slides freely through the round hole and both pieces are held in place with one M8 screw through the brake mount hole.

I'm very happy with the result and I'm looking forward to getting the final brackets cut and fitted. If anybody would like the dxf file for the mount then just let me know. It should be noted, this mount could easily be reproduced with hand tools. The only thing which is important is the placement of the holes. It wouldn't be difficult to drill the necessary parts manually. The only reason I have used CAD/CAM techniques is to more easily achieve a nicer overall look. If you are looking to create a simple motor mount without welding then this should do the trick nicely.