LightningRods

1 MW

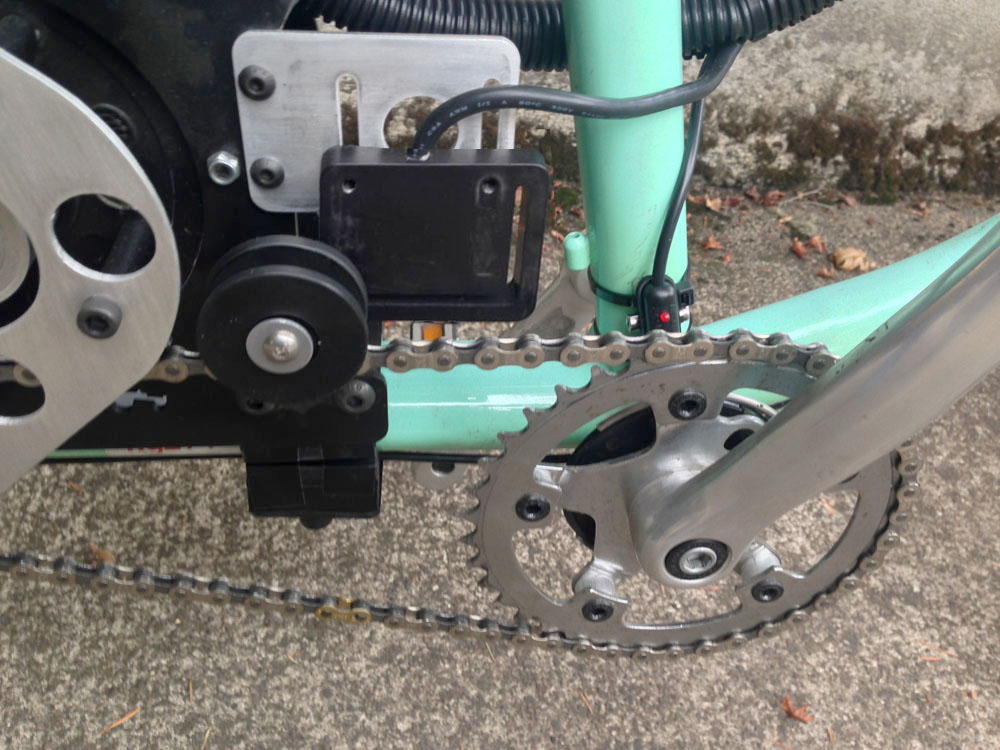

I'm really pleased to hear that you're enjoying your bike. This really is the ideal way to make a mid drive. Reducing the motor down 30x so that you can overdrive it back up 4x makes no sense. Much better to O.D. the pedals 4x and reduce the motor 8x separately.

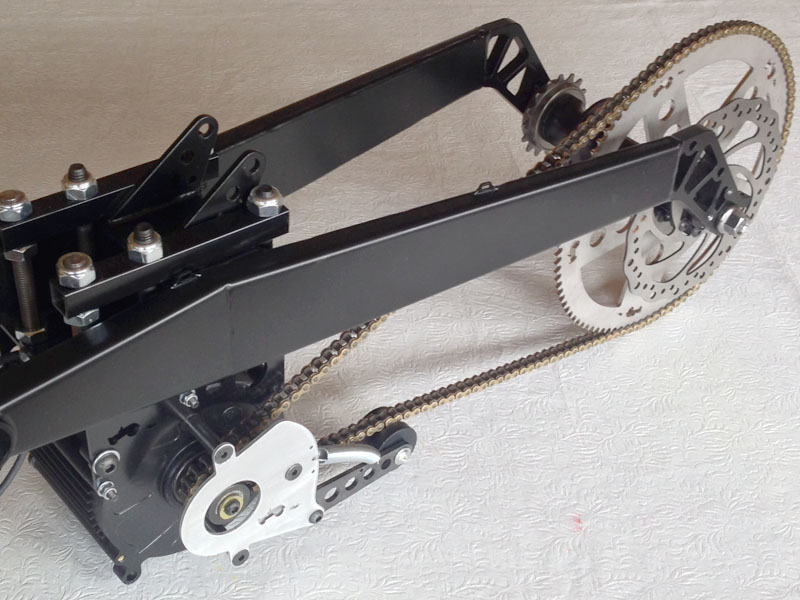

Yes you saw the frame for my new mid mount. It's a Ruff cruiser which is readily available to anyone. The mid mount drive will adapt right over. It fits any frame with some room between the bottom bracket and rear wheel.

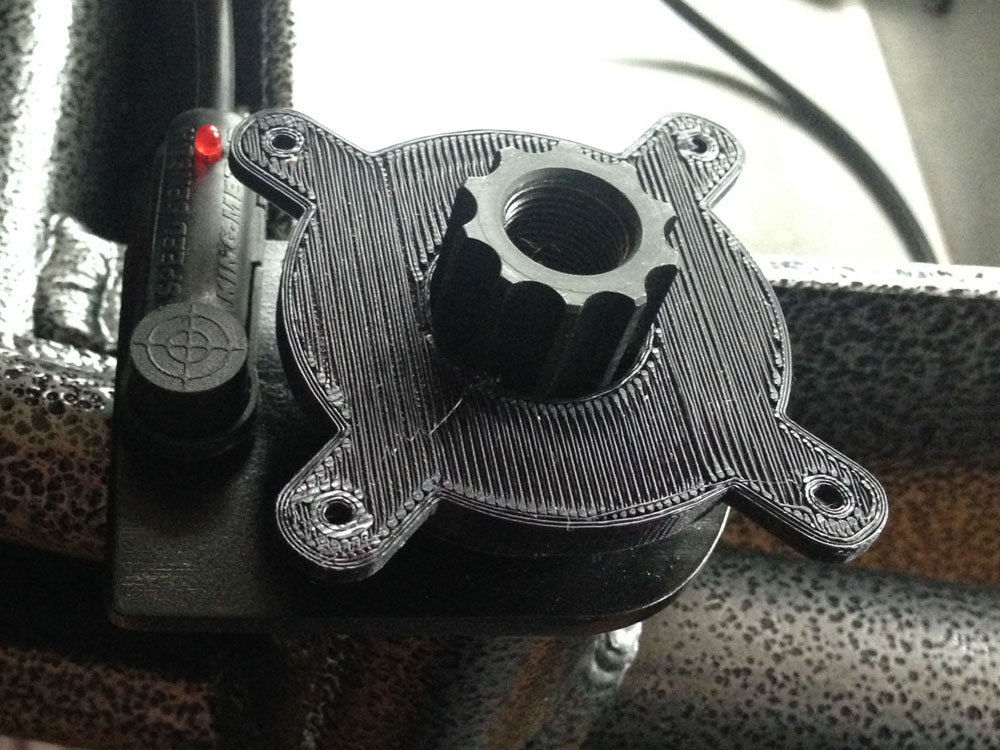

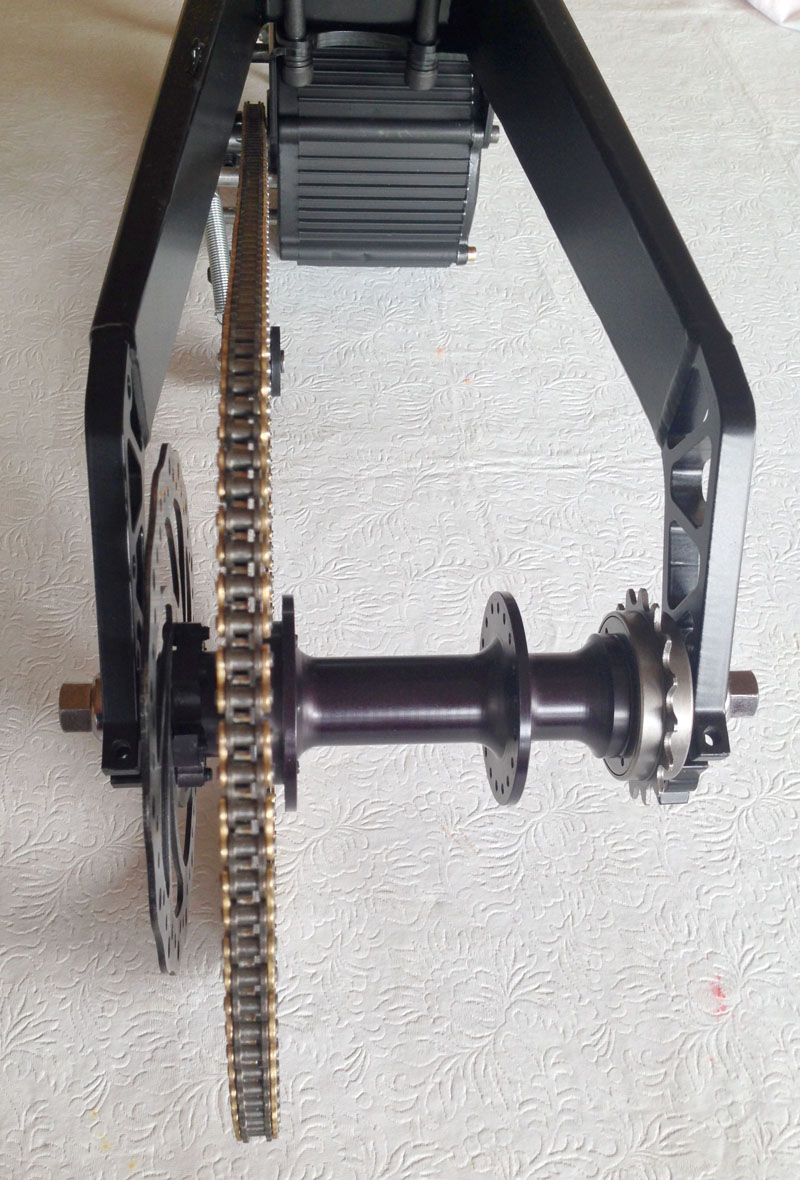

I shipped the first Q76R bottom bracket drive off to Mammalian today. The three prototype rear hubs are at the anodizer in Portland right now. As soon as they're back I'll get his 19" moto rim laced in with 10 gauge spokes and send his swingarm drive as well.

I'm working on a 165-170mm hub with the ratchet ring for a free hub. This will allow users to install a 7 or 8 speed cassette.

Yes you saw the frame for my new mid mount. It's a Ruff cruiser which is readily available to anyone. The mid mount drive will adapt right over. It fits any frame with some room between the bottom bracket and rear wheel.

I shipped the first Q76R bottom bracket drive off to Mammalian today. The three prototype rear hubs are at the anodizer in Portland right now. As soon as they're back I'll get his 19" moto rim laced in with 10 gauge spokes and send his swingarm drive as well.

I'm working on a 165-170mm hub with the ratchet ring for a free hub. This will allow users to install a 7 or 8 speed cassette.