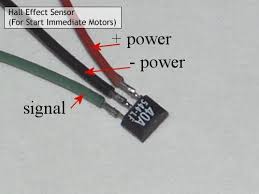

The time has come for me to read hundreds of ES threads and posts to educate myself (I have dreaded that this moment would eventually arrive). Our beloved hub motors are three phase, meaning that the many electromagnet coils in the stator are divided up into three groups. As the rotor magnets pass by the three hall sensors, the Halls "sense" the presence of the magnets, and each hall sensor sends a signal to the controller to energize its designated phase "group"

ebikes.ca / Grin Tech hall sensor PDF:

http://www.ebikes.ca/documents/HallSensorTestingFinal.pdf

From ES technical reference section (many thanks to Fechter):

"How to Determine the Wiring for a Brushless Motor"

https://endless-sphere.com/forums/viewtopic.php?f=16&t=3484

5 step hall sensor wiring determination chart (thanks to "accountant")

https://endless-sphere.com/forums/viewtopic.php?f=2&t=48311#p711261

https://endless-sphere.com/forums/viewtopic.php?f=28&t=57720&start=3275#p1109524

Hall Wires

I would recommend using teflon-insulated wire, since teflon can take very high temperatures, and the small extra expense provides cheap insurance. Hall sensors only carry a 5V ON/OFF signal at low amps, so they don't get hot themselves, but they are usually bundled with the motor phase wires, which may get quite hot. Very thin 28-32 AWG gauge wire is often found on factory hall sensors, but, I have seen 24-ga also used (overkill, but easier to solder)

____________________________________________________

https://endless-sphere.com/forums/viewtopic.php?f=3&t=56423&p=842270#p845104

_______________________________________________________________

_______________________________________________________________

"60 degree/120 degree hall sensor spacings"

https://endless-sphere.com/forums/viewtopic.php?t=957

_______________________________________________________________

Auto Detect

The Adaptto controllers can detect the hall sensor configurations, and automatically configure itself.

https://endless-sphere.com/forums/viewtopic.php?f=31&t=58190

The BMS Battery "KU123" 12-FET controller is reported to have auto-detect function for configuring the halls (called "learning mode").

https://bmsbattery.com/ebike-kit/36...r-ebike-kit.html?search_query=ku123&results=3

"Both Sensored and Sensorless operation, with automatic mapping of hall signals"

http://www.ebikes.ca/shop/ebike-parts/controllers.html

______________________________________________________________

ebikes.ca / Grin Tech hall sensor PDF:

http://www.ebikes.ca/documents/HallSensorTestingFinal.pdf

From ES technical reference section (many thanks to Fechter):

"How to Determine the Wiring for a Brushless Motor"

https://endless-sphere.com/forums/viewtopic.php?f=16&t=3484

5 step hall sensor wiring determination chart (thanks to "accountant")

https://endless-sphere.com/forums/viewtopic.php?f=2&t=48311#p711261

https://endless-sphere.com/forums/viewtopic.php?f=28&t=57720&start=3275#p1109524

____________________________________________________Here is the information that I got back from Edward Lyen on checking the hall sensors:

"To check the hall sensor, turn the controller on, and feed the +5V (red

wire) and negative (black wire) to the hall sensor(s) one by one. You

then use a multi-voltage meter and measure the output signal output

(from yellow, green, or blue wires) from your volt meter. When you

turn the motor slowly by hand, you should see volt jump from around 0V

to around 5v."

Hall Wires

I would recommend using teflon-insulated wire, since teflon can take very high temperatures, and the small extra expense provides cheap insurance. Hall sensors only carry a 5V ON/OFF signal at low amps, so they don't get hot themselves, but they are usually bundled with the motor phase wires, which may get quite hot. Very thin 28-32 AWG gauge wire is often found on factory hall sensors, but, I have seen 24-ga also used (overkill, but easier to solder)

____________________________________________________

Honeywell SS41 or SS411A are commonly used ebike halls - both are rated to 150degC and either are suitable replacements in hub motors.

https://endless-sphere.com/forums/viewtopic.php?f=3&t=56423&p=842270#p845104

_______________________________________________________________

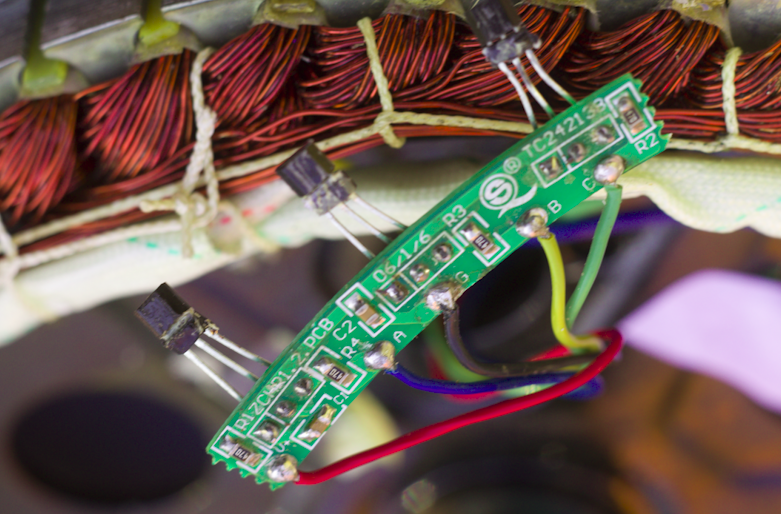

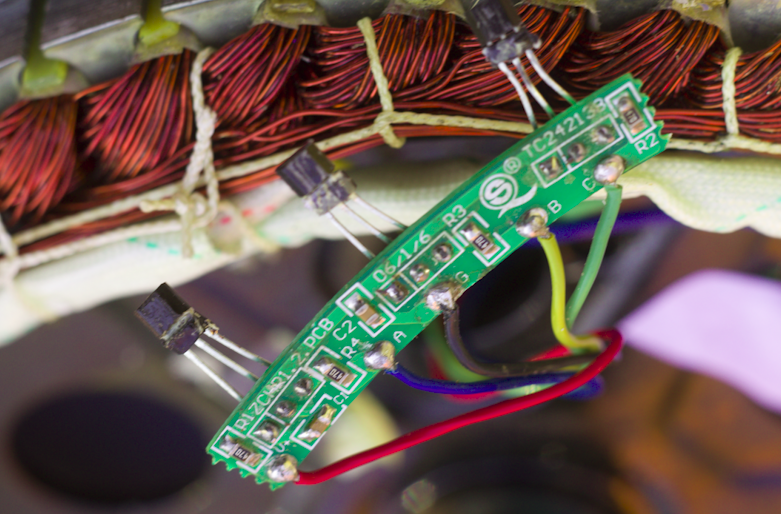

the little green PCB board is there to hold the hall sensors before they install them in the motor, preassembled, and it has the small capacitor to absorb noise on the power line. It also holds the hall sensor legs out of the way and keeps them from shaking and flexing.

_______________________________________________________________

"60 degree/120 degree hall sensor spacings"

https://endless-sphere.com/forums/viewtopic.php?t=957

_______________________________________________________________

Auto Detect

The Adaptto controllers can detect the hall sensor configurations, and automatically configure itself.

https://endless-sphere.com/forums/viewtopic.php?f=31&t=58190

The BMS Battery "KU123" 12-FET controller is reported to have auto-detect function for configuring the halls (called "learning mode").

https://bmsbattery.com/ebike-kit/36...r-ebike-kit.html?search_query=ku123&results=3

"Both Sensored and Sensorless operation, with automatic mapping of hall signals"

http://www.ebikes.ca/shop/ebike-parts/controllers.html

______________________________________________________________