regen on 86volt with v2

seems to work fine no load conditions, wheel off the ground, was a little delay before regen kicked in, not immediate, but only a small delay . Measured voltage of pack at start was 82.4 volt ( cobalt lithiums( 30ahr), not fully charged, fully charged is up around 86volt), motor was x5303 , no load max rpm with v2 was 978rpm ( measured with hand held dig. tacho), at max rpm battery voltage was 80.8volt, current drawn by x5 at no load was 6amps ( quite large).

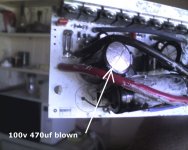

When regen was engaged at max rpm, volts went up to 85volts ( good news no where near 100v max of the 4110 fets), though pack was not fully charged would expect a bit higher with fully charged pack, max amps back into batts ( very briefly was 16amps).

Appeared regen not working when did a road test, has anyone else had issues with the regen on v2? I might just have a bad connection somewhere.