I destroyed the rim by replacing the torn out brake pads a little too late a few times.

The original rims where strangely machined and made to take a lot of abuse from the 1500W gigantic motor in the middle.

Ah, so the pad surfaces were damaged?

To be sure, are the original rims the Weinmann in the posted images?

If so, the "crack" in the first image is the rim join, which is just pinned rather than welded for that rim (perfectly normal).

I don't see a crack in the other image. Perhaps if you take pictures in direct sunlight the camera will focus on them better; some cameras only focus well in close-ups in "macro" mode; if it doesnt' have this mode you may have to keep the lens farther from the subject to get crisp focus.

So, one day i went to a store very far away and bought some pads and hit a very evil bump on the way there and on the way back I heard a sound and I was lucky that I wan't on a very steep hill or too fast for it was close to midnight in a farms hilly area. I had to spend a fortune on a large uber and after inspection home I noticed that the tube was slit and the tire got out of the rime and the rim had all kinds of cracks that can't be fixed.

I can't see cracks in the images posted. Are they at the nipple holes? If so, that's common for too-large spokes because the tension is too high for the rim strength.

FWIW, cracks in the rims of any kind generally can't be fixed; if you had the ability to weld them with the proper equipment, clean up the welds, and heat treat as necessary afterward...but it's probably not worth doing that.

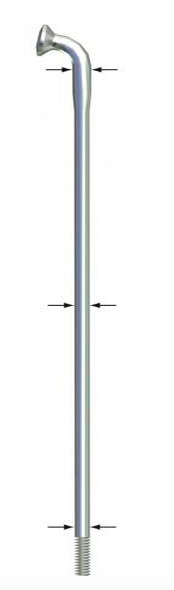

This image

shows the replacement rim is a "deep" rim, so it uses a lot shorter spokes than the original.

I am not sure what you're showing in this image:

That is very good to know. I was kind of hesitant/anxious to replace the spokes to more common ones because I have a very serious (as opposed to leisure) use for the bike and for the extreme kind of treatment explained in the previous paragraph and was thinking that they used this motor/spokes/rim combination for a good reason and there is no need to gamble with my safety or at least get stranded in the dark far away.

They probably used them because it's cheaper. If they built your wheel for you specifically for your usage, it might have been a deliberate choice, if they are a good wheelbuilder. But if it was really just a Voilamart kit, then they don't likely build anything, just buy stuff already made for the lowest possible cost.

My uses are all serious, too, as bikes/trikes are my only transportation, and I regularly move 200-300lbs of groceries a few miles from the store to home with the SB Cruiser, and our streets are not all in very good shape, especially at the edges of the roads where I must usually ride in traffic. I've also hauled a piano home a few miles with a trailer I built, which uses four regular bicycle wheels, with regular bicycle spokes and rims and tires, and the same trailer has hauled a few hundred pounds of dog food both before and after adding the two outboard wheels (for the piano haul).

I've spent quite a while learning what *not* to do with wheels, tires, etc., pretty much all the hard way. :/ I'm no wheelbuilding expert, but they're good enough to do the hard jobs for me.

The 20" rims on SB Cruiser that take the abuse are unknown brand, but were what was used on the first versions of the Zero electric MC when it was more like a powerful ebike / dirt bike. I use 2.25 x 16" motorcycle/moped tires on them.

I'm not using rim brakes now, so the rims don't have machined surfaces, but until very recently (relative to the decades I've been riding) I used only rim brakes. (I switched over to disc because of a broken fork and the options for wheel and fork options I had at the time were limited, and I wanted to experiment, cheaper to change brake types than anything else, and they've worked out fine since then. Depending on the bike design I'm working with at the time I'd still use rim brakes where appropriate).

(If I were to build SBC now I would use 29" or 26" wheels on all three corners, and 2.5-3" wide tires designed for thickness and stickyness (don't care how fast they wear out as long as they stick to the ground for handling and braking, and are at least several mm thick). Would probably move to 14/15 double-butted spokes, and a good "heavy duty" rim like perhaps the Weinmann "e-cargo" series, if they have some non-fat-tire options, or even the one Chalo linked for you)

There was another reason. Trying to find a 15-16cm thin spokes (relatively uncommon) may cost me about what they're asking for their rim or more. I called a few shops and talked to very nice people who advised me against drilling the nipples holes bigger or changing the lacing pattern or doing any modification to those cheap kits because their spokes will start braking "at the drive way".

Please recommend a store/online source where you would get your spokes.

So far I've gotten mine from ebikes.ca (the LBS I'd've used isn't around anymore), but any bike shop online or local that cuts spokes can do what you need.

IME so far, they generally cost about a dollar to a dollar fifty per spoke+nipple, so probably around $40-$50 for a 36-spoke set (plus a few spares in case you ever need them; I usually order 40 for a 36 spoke build), and if you need them a bag of spoke washers to fit on the hub's spoke flange at the head end of the spokes, and nipple washers if you need those for inside the rim to let the nipple sit at the correct angle to stay in line with the spoke are available.

wheelbuildingparts.com

I always thought that modifying (cutting and re-threading) spokes require pricey specialized tools

It does...but you don't need the tools unless you are making a lot of spokes; it's cheaper to buy them the way you want them for just one or two wheel builds.

Even with a 1500W 26" and a heave rider and very long bumpy hilly rout?

Will do, but can you please recommend a place that sells weird spokes at decent prices?

Well, you don't want wierd spokes, you want normal ones.

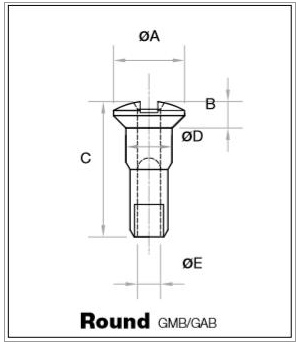

I've never used this specific site before, but decent prices for good spokes are like these

A butted spoke is drawn to its specific profile, which defines its high strength. The strongest spoke in Sapim’s product range, the Strong is developed for specific and heavy usage such as tandem, e-bikes or heavy load use. In case of large hub holes, the Strong is the recommended choice...

wheelbuildingparts.com

about $0.85 each plus nipples like these

wheelbuildingparts.com

for about $0.30 each, and spoke / nipple washers for about $0.20 each.

If you do like I do and order a set of 40 for a 36 spoke build, and you need all of those, it's about .85 + .30 +.20 + .20 = $1.55 per spoke, which would be about $60 for the whole thing, not including shipping.

I have a ton of those that came with it. Those are 15.5cm from tip of threads to bend (are there standard lengths list somewhere? are there standard lengths at all?)

Spoke length is specific to the hub and rim being used, which is why there are spoke calculators to figure out what exact length you need for any particular wheel build.

Some places do carry commonly used lengths, and if you happen to have one within a couple mm's of the right length you may be able to use them, but too short means insufficient amount of the threaded part of the spoke in the nipples, and that can sometimes break the nipple or strip the threads, if it's bad enough.

and are 2.6mm thick (looked for a table that related mm to gauge online and couldn't find any, unless it is the same gauges of electric wires)

If you use "Spoke mm to gauge" as the search, a few of these come up:

mostly at places that sell wheel-building parts.