j bjork

1 MW

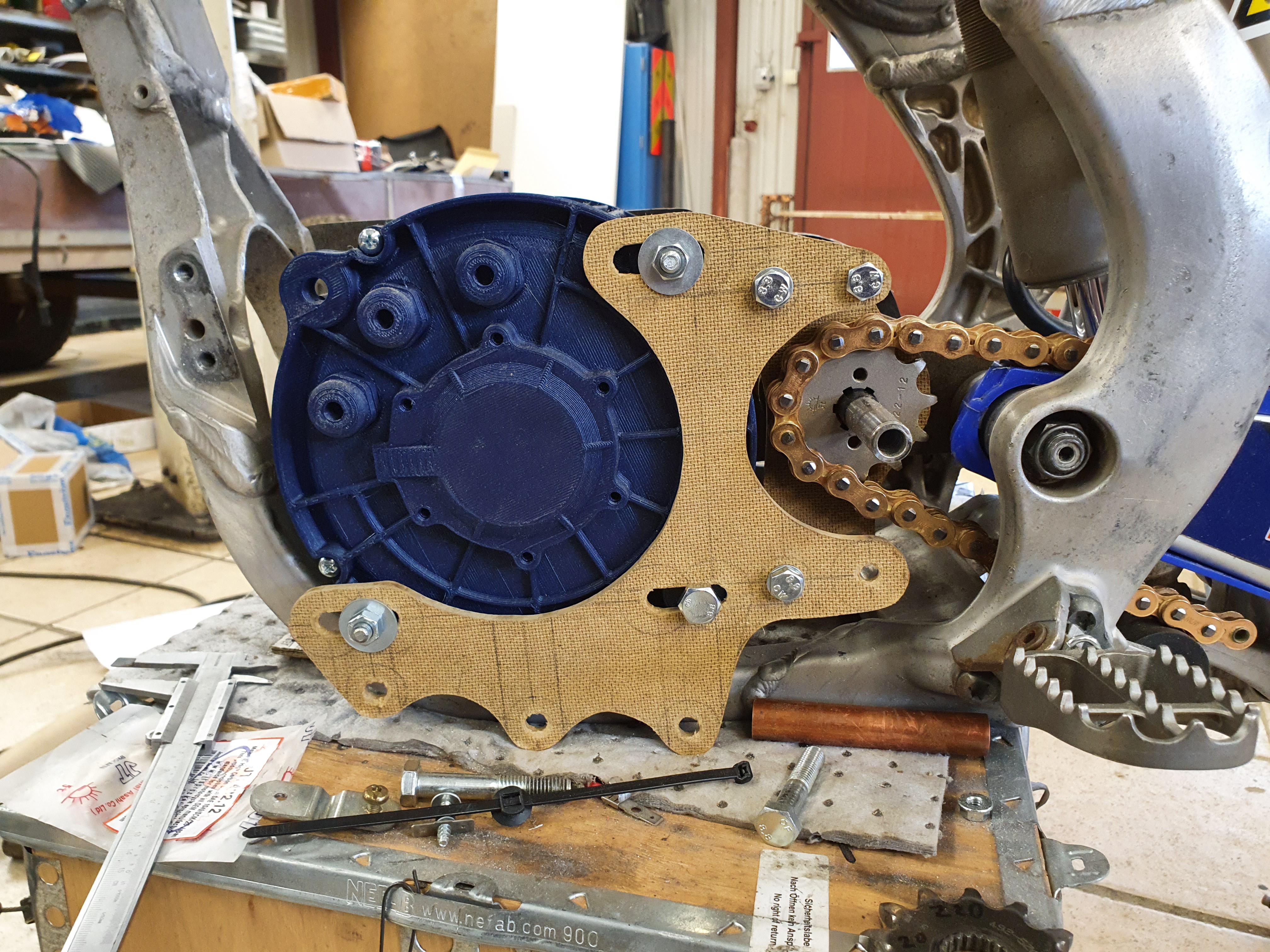

Elektrosherpa said:From my experience of 45 years with motorbikes, I would say: this is TOO TIGHT.

In any case I would add a chain tensioner of whatever kind (something with a spring or an oil dampener) in this primary chain drive,

since a chain is permanently changing its length, due to wear, and forces transmitted.

And I think, a possibility for moving one of those two axles would be required, for adaption of the chain tension

(as it is usually realized in motorbikes' rear swing arm axle mounts).

It is supposed to be 3mm between the chain and the housing to the rear of the chain, but this is more like 1mm..

I will make some changes and try to get the 3mm that I planned, I hope that will be enough.

Otherwise I guess the chain will make the room it needs :wink:

It should be possible to mill or grind out some material just where the chain are afterwords if needed, and be able to keep at least 3-4mm material for the sealing surfaces.

Do you really think a tensioner will be necessary for this short chain? I am trying to avoid it, to have less things that can brake..

The motor is movable back and forth to adjust tension. The chain will also be in an oil bath, so I dont think it will wear very fast.

It has room to move everywhere else, just not to the backside of that sprocket..