j bjork

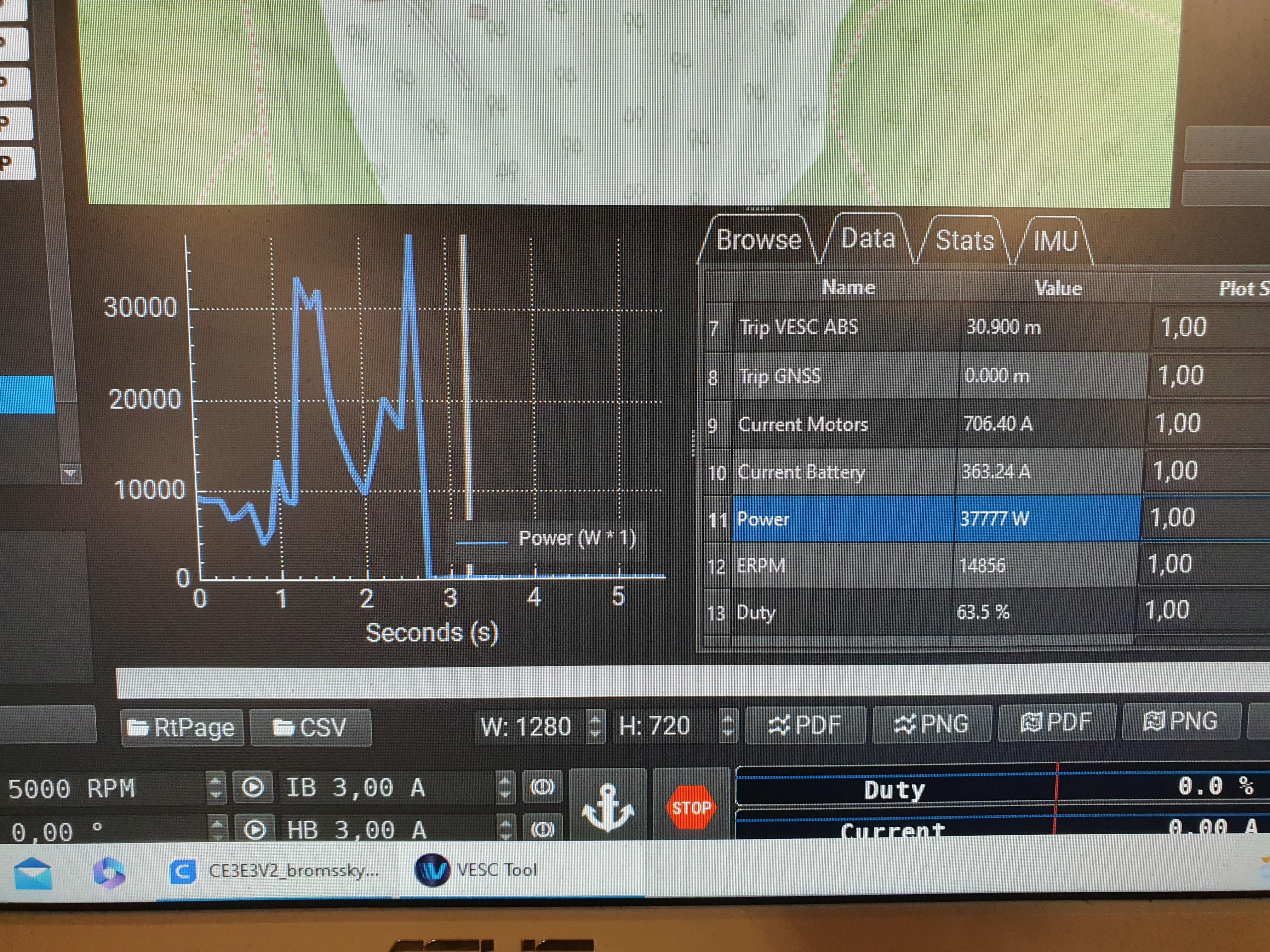

1 MW

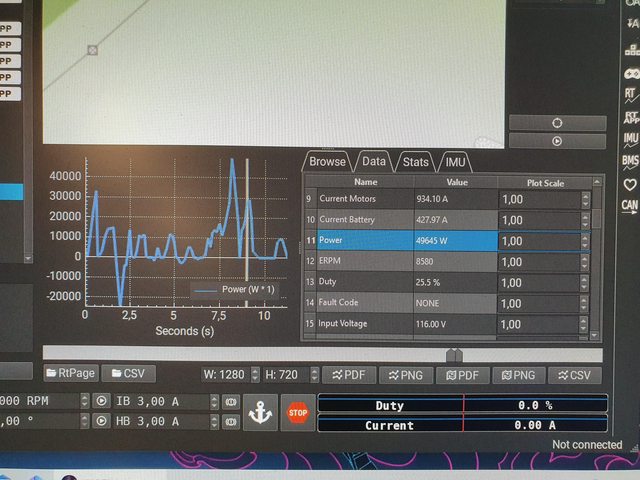

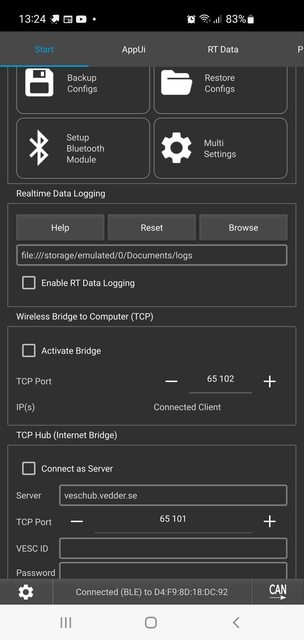

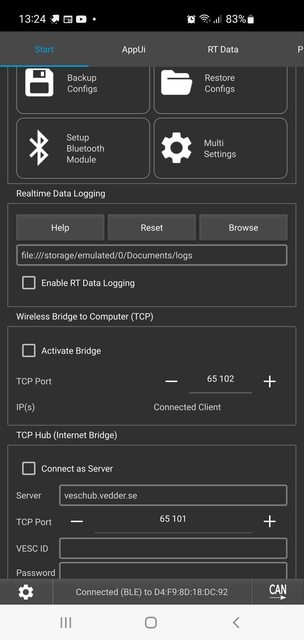

This is logged with the phone:

I just click "enable rt data logging", I dont think I can choose what is logged or how often.

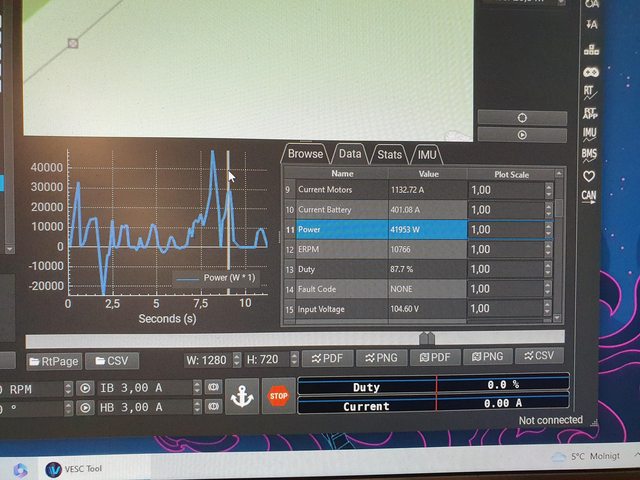

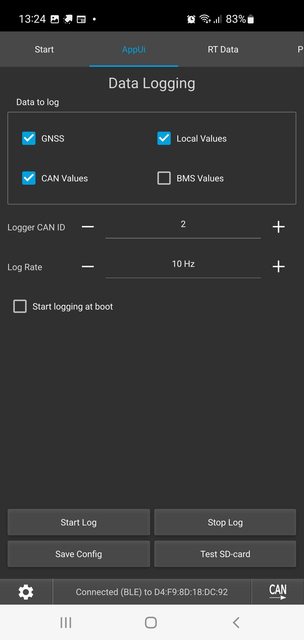

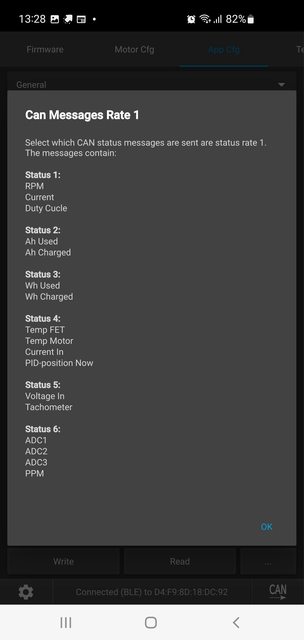

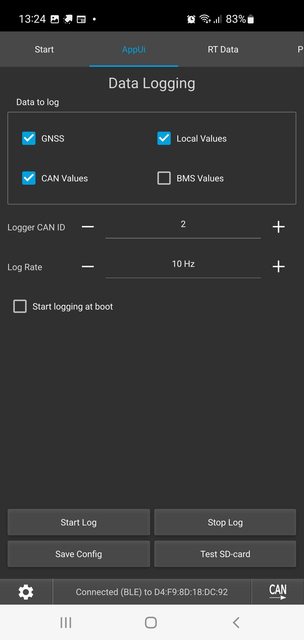

I can also send can data, then there are more choices:

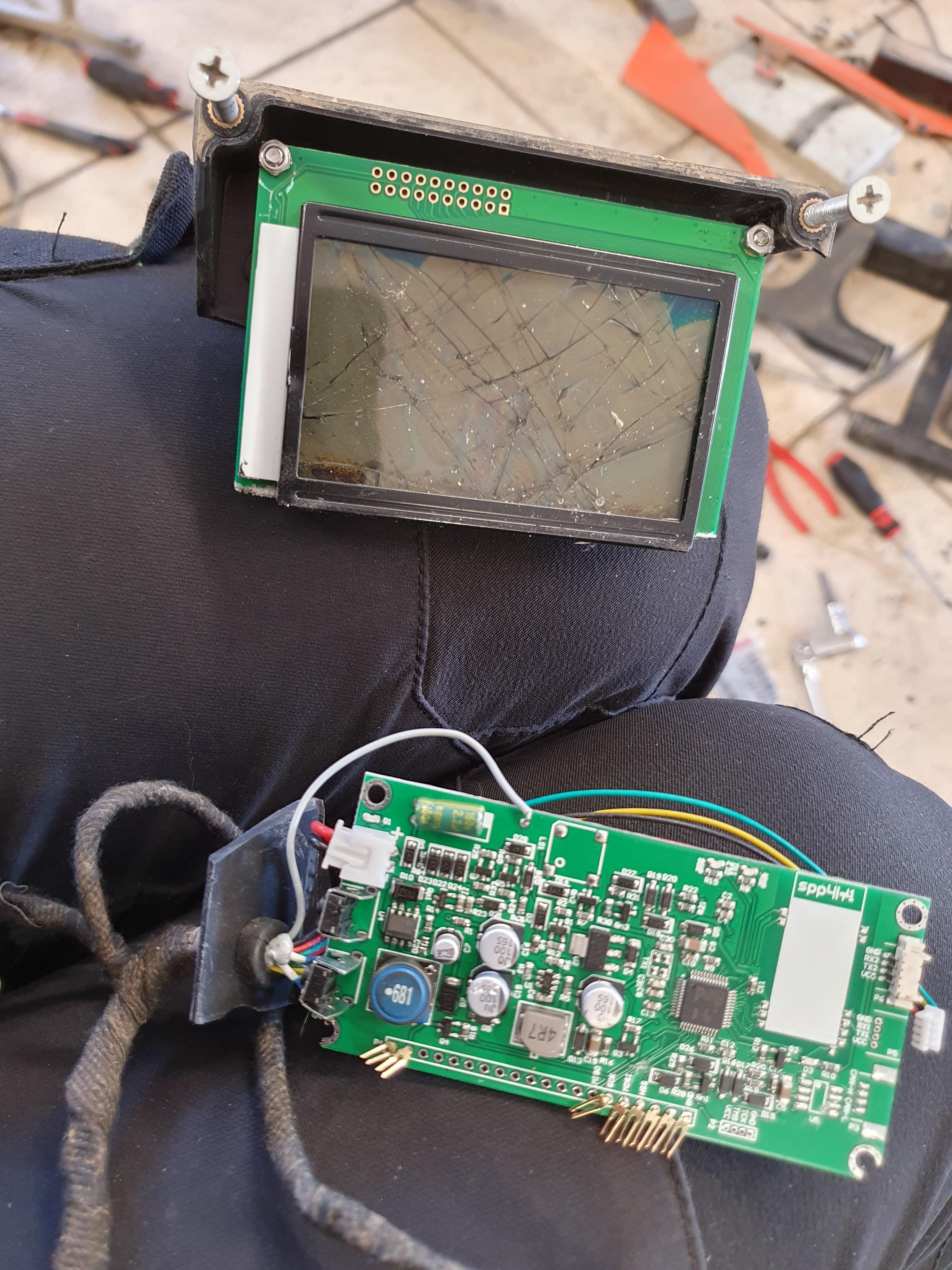

I tried earlier to log with the shul express (copy of vesc express), but it seems like the can receiver died or something.

The controllers can buss where sending like crazy, but the express were dead silent. I think it didnt even had the base voltage, but I am not sure I remember correctly. It is in the thread somewhere.

I just click "enable rt data logging", I dont think I can choose what is logged or how often.

I can also send can data, then there are more choices:

I tried earlier to log with the shul express (copy of vesc express), but it seems like the can receiver died or something.

The controllers can buss where sending like crazy, but the express were dead silent. I think it didnt even had the base voltage, but I am not sure I remember correctly. It is in the thread somewhere.