You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Road to Higher HP 100-200-500+ HP

- Thread starter Arlo1

- Start date

But I started with a bigger magnet area and evey time I decreased it the torque went up.....Miles said:Arlo,

I think you need to increase the magnet area, not decrease it.........

I used a winding scheme from powercoco but maybe I need to wind it in a different way?

major

10 kW

Arlo1 said:But I started with a bigger magnet area and evey time I decreased it the torque went up.....Miles said:Arlo,

I think you need to increase the magnet area, not decrease it.........

I used a winding scheme from powercoco but maybe I need to wind it in a different way?

Looks to me like you're running on reluctance torque and the magnets are basically air gaps.

No making them thicker made more torque and making them higher N value made more torque as well.major said:Arlo1 said:But I started with a bigger magnet area and evey time I decreased it the torque went up.....Miles said:Arlo,

I think you need to increase the magnet area, not decrease it.........

I used a winding scheme from powercoco but maybe I need to wind it in a different way?

Looks to me like you're running on reluctance torque and the magnets are basically air gaps.

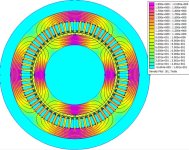

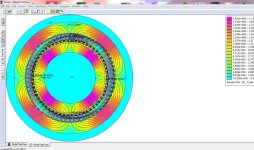

:Edit although the lines of flux don't go thought the magnets like farfels example. Hmmm I will have to do some playing. I think the winding pattern is not right.

Power coco is not letting me choose WYE or delta... but I don't think that matters to much.

Yes sketchup. I have modified the magnets so many times in femm they have become ugly. The 6061 is in phase c I never changed it to the copper because phase c is not energized.Miles said:Arlo,

Was that drawing created in Sketch-Up, or something???

You seem to be using a mix of solid slot 6061 and Copper wire (10 turns)?

I think I need to understand the winding better to get this right maybe I need to split each stator slot into 2 and have it shared with another winding? I meen when I wound colossus there is a tooth on each side of the slot and each tooth had windings around them so 2 different windings in the same slot. How you label slots in femm is a little weird to me.

I was trying solid slot with aluminum but I can't seem to get it to work with any number of magnets.

I drew a lot of it in femm it self just the stator in sketchup. I can use something else but I don't think that's my problem. I will re draw it after getting measurements more acuratly for the tooth sizes etc. But as for right now I have something very wrong.

Sure, it's not causing the anomalous flux circuit. What happens if you only have a small gap between the poles (about the thickness of the magnets) and also take away the upstand of back iron at this point?

At the moment, you are concentrating the flux from the back of the magnets and giving it a preferred path between the magnets.

At the moment, you are concentrating the flux from the back of the magnets and giving it a preferred path between the magnets.

Ok. I'll have a go at re-constructing this.

Maybe there are ways to optimise a Sketch-Up file before exporting to DXF? The file, as exported, is hardly worth messing with. Sketch-Up is a polygonal modeller - best used for "illustrations" only.

Maybe there are ways to optimise a Sketch-Up file before exporting to DXF? The file, as exported, is hardly worth messing with. Sketch-Up is a polygonal modeller - best used for "illustrations" only.

First attempt.......Miles said:What happens if you only have a small gap between the poles (about the thickness of the magnets) and also take away the upstand of back iron at this point?

Attachments

254mm id (10 inches) 5 inches long.Miles said:Is the stator inside diameter 200mm?

What is the stator length?

Don't worry about it I measured the stator slots and teeth last night more accurately and I will re draw it.

jonescg

100 MW

Sounds like you are building a radial flux motor of the same dimensions as a half-decent axial flux motor. With liquid cooling it might just work

Oh, I might not need to build my own motor for the CRX - I was in touch with Evo-GKN and they said they will sell small numbers to any firm who has intentions to buy many more in the future. So if we can get a consortium together we can make the AFM140 the motor of choice for AC conversions. Then place a big order

An AFM240-4 in your machine should rip nine colours of shit through the competition

Oh, I might not need to build my own motor for the CRX - I was in touch with Evo-GKN and they said they will sell small numbers to any firm who has intentions to buy many more in the future. So if we can get a consortium together we can make the AFM140 the motor of choice for AC conversions. Then place a big order

An AFM240-4 in your machine should rip nine colours of shit through the competition

I don't have your kind of money man lol. How much $ we talking? I really want to make a PM motor!jonescg said:Sounds like you are building a radial flux motor of the same dimensions as a half-decent axial flux motor. With liquid cooling it might just work

Oh, I might not need to build my own motor for the CRX - I was in touch with Evo-GKN and they said they will sell small numbers to any firm who has intentions to buy many more in the future. So if we can get a consortium together we can make the AFM140 the motor of choice for AC conversions. Then place a big order

An AFM240-4 in your machine should rip nine colours of shit through the competition

jonescg

100 MW

Arlo1 said:I don't have your kind of money man lol. How much $ we talking? I really want to make a PM motor!

I don't have that kind of money either

What don't you understand about winding it? It gives you the winding pattern on the exPowerCroco site. Assuming you're going for a single layer winding, the coilspan is 15 slots - 5 slots per pole per phase - two iterations.Arlo1 said:I think this will help me understand how to wind it.... I think?

There is 2 more of the Cranes this motor come out of standing behind work..... I could make a 15 inch long stator if neededjonescg said:I'd love to turn an induction motor into a PM motor, and a nice big diameter one too.

Similar threads

- Replies

- 18

- Views

- 707

- Replies

- 12

- Views

- 179

- Question

- Replies

- 10

- Views

- 592

- Solved

- Replies

- 6

- Views

- 3,028