casainho said:

For next steps, I would make the UART custom profile of Nordic working between the SW102 and Android app.

Casainho,

I agree and disagree

I really think the one is not excluding the other

But as you mentioned "think big, start small"

The Nordic UART Service (NUS) looks to be ideal for a quick implemetation and very usefull for debug reason

=> very same tx/rx buffers used between motor & LCD can be exposed via this NUS

=> the nordic nRF Toolbox app "UART" or a screen in our own Android app can be used to display the raw buffer data

=> we can/should indeed start with this one.

In a second phase we can use the same data to be exposed thru other services

Do I interpret correctly that struct _motor_controller_data is containing all data that need to be displayed on LCD and/or App

and that struct _configuration_variables is containing all data that should be editable in App to be send back to Motor ?

Best BLE practice would still be to create a custom service with defined charasteristics for each element in those structures

=> like this you can even view the data in a less raw format with standard tools like the nRF connect

https://www.novelbits.io/bluetooth-gatt-services-characteristics/

https://learn.adafruit.com/introduction-to-bluetooth-low-energy/gap

How can we split the work ?

I could take the AndroidApp part

and eventual try to do the bleHandling in the nrf51 (in the assumption that all data is exchanged thru the 2 defined structures)

- struct _motor_controller_data -> ble (NUS) -> App

- App -> ble (NUS) -> struct _configuration_variables

Nordic SDK example :

https://infocenter.nordicsemi.com/t...0/ble_sdk_app_nus_eval.html?cp=5_4_0_4_1_2_24

Who can do the Motor -> struct _motor_controller_data

& struct _configuration_variables -> Motor part ?

casainho said:

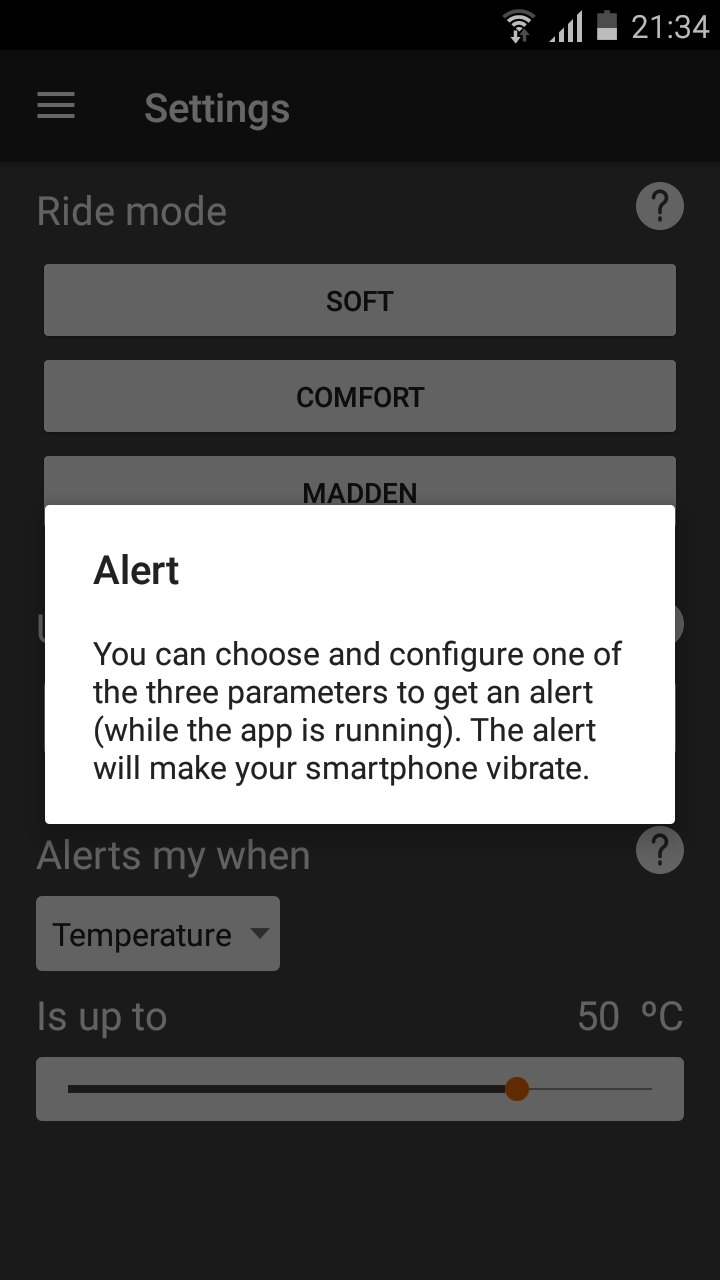

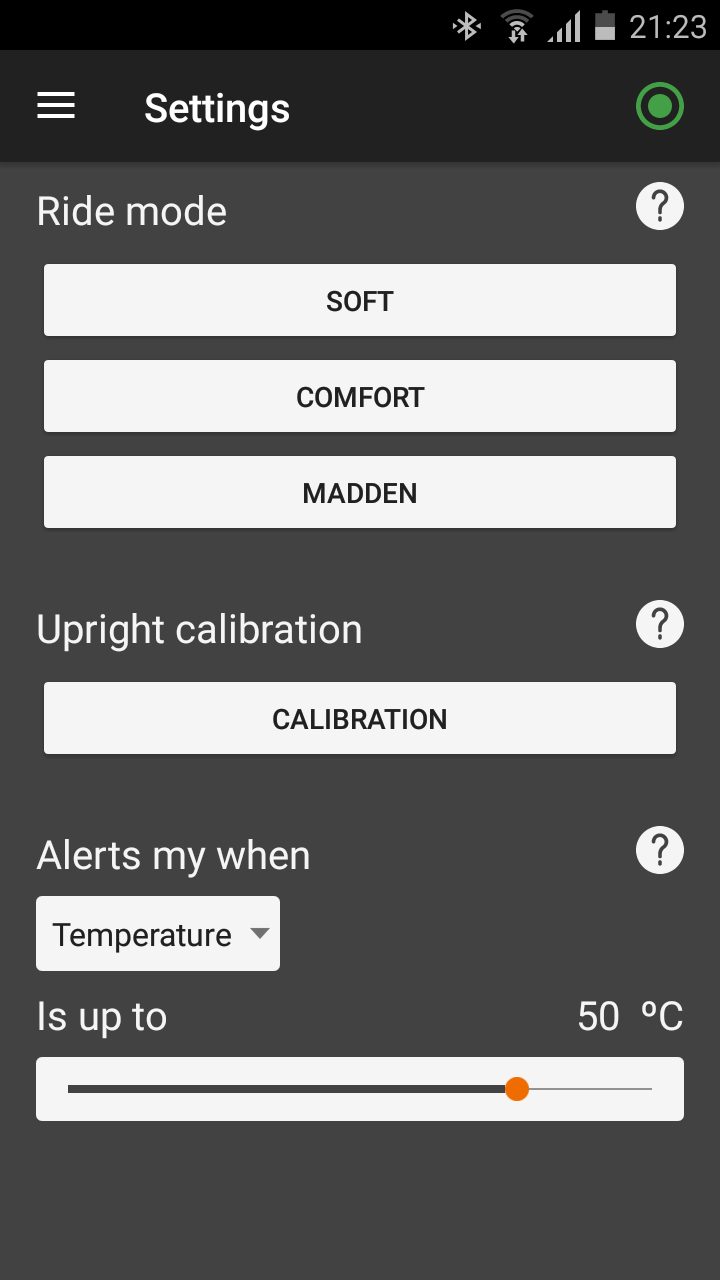

I think it is also very important to define the design of mobile app and his structure in terms of menus or options. At least, I see a minimum like on 850C LCD: main screen showing real time data like wheel speed, motor power, etc (in numeric fields only for a start) and a configuration screen.

Do you agree that this would be done in 2 steps ?

first implement the NUS (and maybe the custom profile) with 2 simple screens corresponding to the fields in the structures

In a second step we can make it fancy with Graphical representaions of the real time data and a more userfriendly configuration screen.

I would do the UI en menu design of the "fancy" one once we have the NUS version ready

Some Practical questions

- what IDE do you use ? the Segger Embedded Studio or other ?

- what programmer do you use for the sw102 ? SEGGER J-Link, STlink v2 ?