hkj

100 W

- Joined

- Nov 5, 2018

- Messages

- 106

Not noticing that often at all @TorEddy. Maybe I'm just lucky... Still using the front sprocket that came with the belt kit. I felt it happen but it's nothing I notice that often. Mostly run the bike on mode 2 or 3. Does it happen with throttle applied or even when pedaling?I'm still experiencing belt slippage on the new 14t motor pulley. I'm running the latest hardware from LMX and a carbon belt but still experience slippage even in mode 3 of 5. The belt is holding up and looks good, but the slippage is really loud and annoying. Am i the only one experience this or does everybody else have the same problem?? I would prefer a 15t motor pulley to avoid this, even though i loose some torque in low speed climbing.

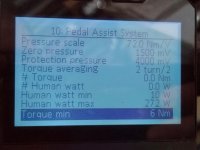

Instead I have issues sometimes with the bike adding power even though I'm not pedaling (throttle removed)

The controller gives me like max power making for some interesting moments. I can also have the opposite, I'm not getting any power at all for a brief moment. Anyone know what that is all about?

Also swapped fork for a Zeb Ultimate (190mm). The old one almost came apart and I couldn't find any spare parts for it.