According to this thread, MAC started using .27mm lamination thickness in Nov of 2016:You took my spot!

The mac is a great motor and I'm real sad i never got to try the mac with 0.27mm laminations.

I think i'd still be the #1 leaf fan if i didn't like my bike wheels in the small range, which lets me downsize my motor and get away with smaller. You will be pleasantly surprised at it's efficiency relative to the mac.

It's a real shame that leaf hasn't innovated anything new in their motors for a decade though.

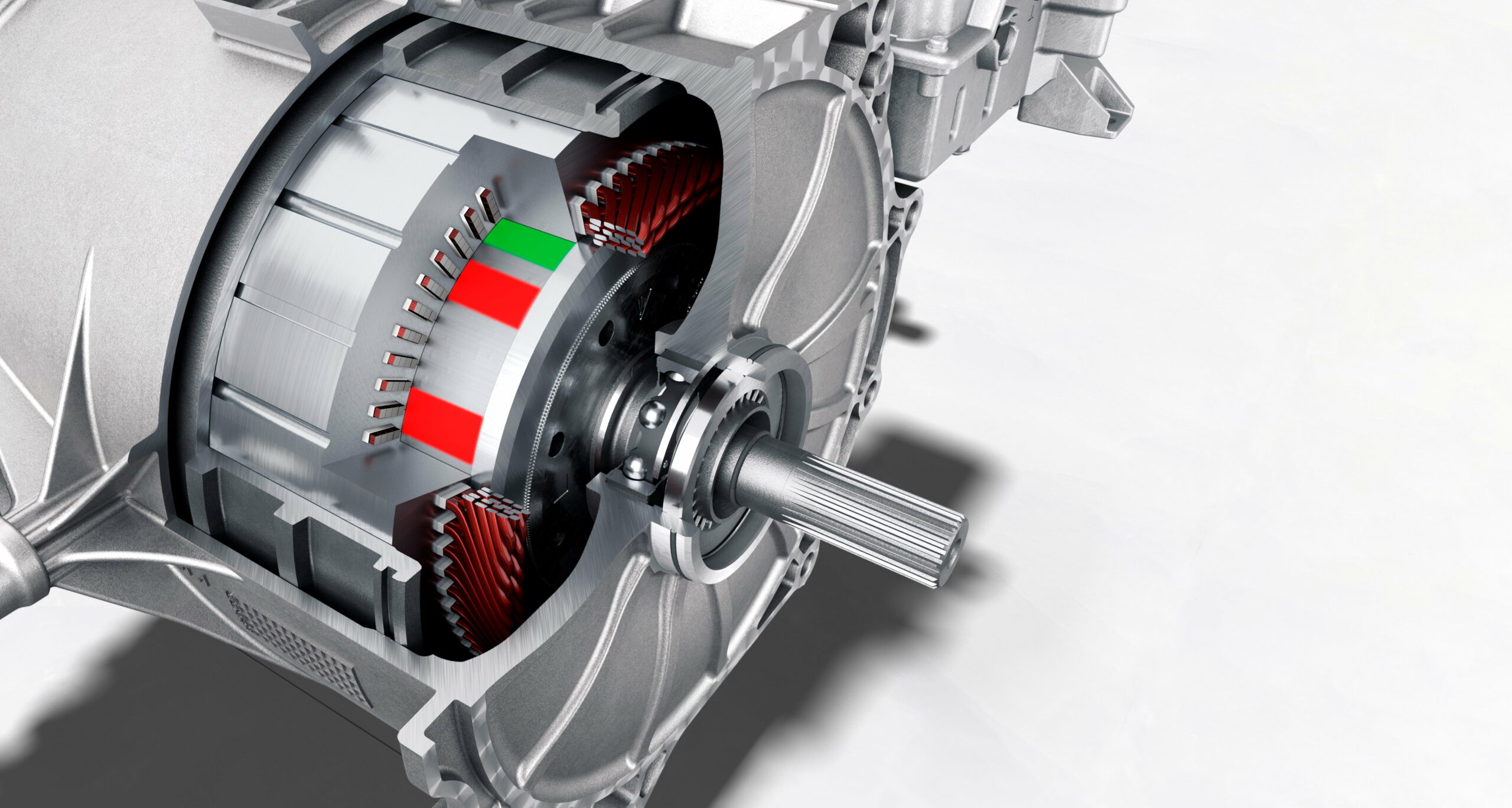

0.27mm Thichness Motor Stator Laminations - MAC Motor

0.27mm thickness means what? A piece of paper? A hair? A $100 currency? Today I will let you know a GOOD NEWS! MAC Motor has started using 0.27mm thickness stator laminations for every motor, every one! Forget 0.5mm, forget 0.35mm; now, it's time for 0.27mm Higher Grade Stator Laminations...

I sent "Jessie" (the post author that said it) a message asking what they are currently using.

Maybe we could get Leaf to go to high quality .27mm laminations as well.

It probably cost a little bit more for high quality thinner laminations but it sure does help with efficiency and over heating...just saw where "Caleb" posted it before I did.

Sending Grin Tech a message to see what they say about the GMAC as well...I'll let you guys know if I get any answers.