http://adaptto.com/Products/BMS/

That BMS above the chart is the only one that balances at 4.1V instead of 4.2V. I got that off this forum when I googled it doing research.

I have the 10S and 13S factory built Lion packs I just bought a year or two ago and sometimes I do not use them for a week or more at a time. They sit around. Maybe 3 times a month each pack for 5 to 10 mile trips.

Since I saw that chart I have been trying to pull them off the charger at around 4V. A little less if possible. I know that they need the 4.2V to balance properly so now if I intend on using them I plug them in two to three hours before I run them and as soon as the light on the charger turns green I treat it like a traffic light. GO.

That way they are not sitting around for days or weeks at 4,2V. It just makes sense. Not sure how many more cycles I will get but hopefully a lot. At least double. I know just charging at 4.2V will take away many cycles but how many ? I read that it causes more damage to the cells just letting them sit in that state . 4.2V for awhile. The longer the more damage so Now as soon as they hit full charge , 4.2V I haul them downstairs , hook them up and run them.

I can fit 12 cells in a row on the bottom. I can stack up to 6 high. Since I am building 10P that is 6S - 10P and if I stack 5 high with the two cells on the end I can get a 1S - 10P pack and a 6S - 10P pack in each of those. Two of them would be 14S then. If I balance charge the 6S packs at 4.1V with the LiLo balance function I should be good. I will try and do the same thing though. Stop at 4.0V or 3.92 - 3.95 and plug it back in the night before or a few hours before I run them and balance charge to 4.1V with the LiLo function. From what I have read it is also safer with old used batteries.

I have a lot of cells to test so came up with a system last night. I can mark voltage with a sharpie so separating into banks of 10 should be simple. The thing that will hold everything up is separating all the parallel packs I already wired up then waiting a week to see where each cell voltage settled to. Used cells of different make require a lot more time to build as extensive testing and a week of shelf life is required.

If I could get a sweet deal on LiPos I think I would order them as this 14S pack will take a lot of time. At least a month or two. Same with the LIFEPO4s. I still need a spot welder. What is worse some of the cells I soldered wont pull apart. Some will but still solder on the cell so will not be able to spot weld them unless I remove the solder and clean the cell. I really do not know what to do with those ???????????????????????????????/ Any suggestions will be appreciated.

I could not get the nut off that was rusted on so sprayed it with WD 40. last night / early morning. Hopefully will have better luck with it tonight. It is a 48V - 800W motor but ran it at 10S - 36V most of its life. That is what I am working on now. I will upgrade the wiring to 10 gauge and can run the 13S - 7P battery. It will perform very well on flat and up hills. The battery rack that also mounts the controller is also cracked. It did not hold up and just like the Giant Roam it needs to be re built from scratch. The Giant Roam is in brand new condition. This 20" Turbo bike needs a lot of TLC. There is probably rust on other areas of the bike as well.

The Diamondback with the two Bafangs in the van also has a flat on the back. There are two extra Bafangs I am keeping right next to it. I was going to give one away but the guy is in Florida and he left the black dual suspension and the 1,000W 48V unite motor I soldered and two controllers and a chain all at his brothers house in the garage. He never even tried to hook it up so am done. I gave his brother the Clear Creek Schwinn with a 36V 800W motor as well as three 7.5 Ah SLAs. He never rides that either.

I have been more than generous.

I will just remove the Bafang with the flat and throw on one of the Bafangs in the van I am not using.

When I get another flat I will throw the other Bafang on it. It only goes 20 mph but the acceleration from 0 to 20 mph is awesome. It also does small hills no problem and do not even need to upgrade the 16 gauge wiring as there are two controllers and only 350watt motors. I don't push them hard. 1/2 throttle gets it to top speed. If I do encounter a long steep hill as soon as the motors start slowing down I will get off and push it up a hill.

The Currie will be back in less than a week so that can get the 10 gauge upgrade as well. The Bafang on the front wont need 10 gauge wire either. Only 18 amp controller.

The e bikeling motors use 22 amp controllers so will use the 12 gauge wire for them on the Giant Roam. I suppose I will have to re wire the entire 1,500W controller hooked up to the 1,800W brushless motor. The voltage drop and power loss very well could be the 16 gauge wire failing somewhere as that is the most powerful bike I own and was pushing 1,500W thru 16 gauge wire. Hopefully the 10 gauge wire will fix that problem.

I doubt it is the new 10S - 8P battery But if I rewire it and it does the same thing with the 10S battery then I will know. Likewise if the 10S battery cuts out on another bike I will know it is the pack. I will then have to find out which pack. There are two 10S - 2P hoverboard packs and a 10S - 4P e bike pack which has the charge port and charges all the packs in parallel. I separated them and tested voltage and all were the same so put them back in parallel. They are sitting right now at 40V. 4.0V per cell.

If I am planning on building packs ongoing with a spot welder and Weller 100 watt iron with the extra large screw driver tips I ordered I need to set up my workshop to do capacity and discharge testing. Then I will know if a BMS is cutting out or LVC or something.

The next time I go to Wall-Mart I will be getting a large hard plastic Hyper tough tool box. I think it is large enough to stack up at least 9 LTOs. they have a 19" and 22" box I think. I might have to bring an LTO or take measurements. I know I cant mount anything like that to a 20" bike without a rear rack and then will be too heavy in the back.

I wish someone would let me know what is the best DC booster for the job. Looking at 24V in to 48V out. Maybe 36 in but not sure about 15 - LTOs. A lot of weight and space. 12 is 30V and I have 24 - LTOs so kind of makes sense. I will still get > 12 AH @ 48V.

Also I need a good reliable spot welder. I do not want to order the wrong one. I will need to watch a video on how to remove solder. I can heat up the solder with the Weller iron but need a way to remove it in the liquid state so I can clean and spot weld.

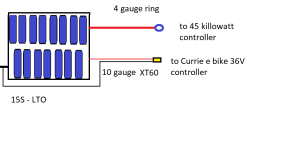

I need to order the ring connecters for the LTOs. I still never got any answer if 24 - LTOs will work with the FX - 75 - 5 motor ?????

The controller is 45 kilowatts I think. I did not know there was thicker than 1 gauge wire but found that chart. I will have to dig half way to China to get to the 45 kilowatt controller to measure the wire. I know it was thicker than car battery wire to the terminals. I need the LTOs to run the FX - 75-5 motor in the future and e bikes much sooner. I might need more LTOs to get closer to 100 volts. What will 60V of LTO do ????? 60 mph ? 70 mph ? I was looking for 90 mph ? How many more 18 Ah - LTOs will I need for 90 mph ????? Will it do 60 mph now at 60V ?????????????

What range will I get ????? < 5 miles ????? < 3 miles ????? I wish DA would do a speed vs range chart and a voltage vs speed chart for 18 Ah Lishen battery and 45 kilowatt controller so I know what I need. There is no way in a million years I will be hooking any of that up. I will need to get it professionally done so I can just turn the system on to run and plug in to charge like any large EV. I do need the right components though as will be paying top dollar for an electrician. If I do not have the right wire , DC breaker or something it will be an expensive disaster.

I hope to get some feedback on any of these topics.

Thanks.

LC. out.

10:43 PM.

Yes. I can fit 12 to 15 LTOs in that tool box no problem. I really do not know how that happened. (middle pic) bottom. They have been kept inside the boxes they came in since I got them. Must have been shipped that way.

I know nothing about LTOs. I don't think they should be touching each other though. I will need to space them with 1/4" pieces of wood to separate them. 6 cells on the bottom with 6 on top if I go 30V. I can cut the wood with a jig saw and glue them together so no cells can touch another. Then hook up the < 1 gauge wire. I will need to order ring terminals gold plated and solder the wires to the terminals.

I really wish someone would post. I need to order a spot welder for the 26650 cells. Something to de solder those also. Something that will suck the solder off the cells when I melt the solder. All the LIFE cells need to be cleaned up and spot welded with copper strips. The bottom pics below show a horrible attempt to solder a single 10 gauge piece. NOT happening any time soon. :lol:

I need to know what is required for the LTOs so I can run the 45 kilowatt controller. Then I need to know about DC boosters. I need a good one to go from 30V to 48 and 60V.

Please let me know.

Thanks.

LC. out.