You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

new eZip motor

- Thread starter latecurtis

- Start date

- Status

- Not open for further replies.

DrkAngel

1 GW

Well ... no!latecurtis said:OK so basically no specs are constant and all subject to change and basically it boils down to is heat. How many watts can the motor put out without overheating ???.

OK so basically no specs are constant and all subject to change and basically it boils down to is heat. How many watts can the motor waste, as heat, without overheating !!!

1200w input cruising at 30mph, (1000w power - 200w heat), might run indefinitely with no problems.

Same motor;

1200w input chugging up a hill at 3mph, (200w power - 1000w heat), might burn up in 60 seconds.

Same with over gearing, much less usable power and much more damaging heat.

I've already pointed this out many, many, many times!

markz

100 TW

Unfortunately you only do that once

:wink:

:wink:

DrkAngel said:Oops, just looked back and saw you are ripping the end tabs off ... ?

latecurtis

100 MW

Oops, just looked back and saw you are ripping the end tabs off ... ?

Yea. If I left the tabs on with the cells that close together they would short each other out. I do not want that ! If I don't cut them before I take the board off I get sparks and short circuits. They are flimsy anyway. Not a secure connection. Just a short circuit nightmare waiting to happen.

I have a lot of e bikes and am building more. However my favorite one to ride is the little 20" Turbo with the 20" front hub motor on the back. It is simple and reliable. It does not pick up a lot of speed going down hills as the direct drive hub motor has resistance so my one little V brake does the trick at least on small hills. There are not many big hills where I am.

I rode the bike to Wall-Mart tonight and just got back a little while ago, I got a Dremel cutting kit to take those cases apart but broke my Dremel trying to get the thing to go in there. It did not fit. I don't know why that is and ended up throwing the Dremel in the garbage. I am not running out and buying a new Dremel any time soon. I feel like just throwing all these garbage batteries in the dumpster and just ordering a 35 Ah - 48V pack. This is ridiculous.

I am probably better off going back to using the hack saw and screw drivers and spending 5 bucks on some work gloves to protect my fingers rather than 20 bucks on a new Dremel. I need to take a long break from building my own battery packs I think.

Not sure what is going on with the old 10S - 10P packs either. They did not want to go up a small hill on the way back from Wall-Mart. I figured they might be low as were in the van and ran them before without charging but thought I only went about a mile at the most and Wall-Mart is like 5 miles round trip. I did not run them hard at all and when I got home they were above 37V.

I never killed a lithium ion pack before. Those 10P packs are the original SONA and Samsung packs I bought years ago. What would cause such a loss in power ??????? Is it severe voltage SAG since they have exceeded their usable life span ????? I could buy one more 22Ah - SLA but think they might also be junk as I fully charged one and put it in the van with my voltage inverter and 1 amp trickle charger and the red light was on on the inverter and the charger was not getting power. That usually only happens after two days not two hours !!!.

The lowest I ever saw them read was around 11V I think. Might have been like 10.9V once. One is much newer that the other but already mixed them up.

I will check it tomorrow I guess. I know I will need batteries. I have about 8P worth of new 10S packs but other than that I am probably screwed. I won't be able to run dual motors with that set up except for the Giant Roam as they are both 500W e bikeling motors. The Currie will be about 1,250W and if I ever get the 26" dual suspension done that will run 2 kilowatt's.

Not really sure what I should do at this point but it don't look good. Only one good 8P pack and these batteries from Battery Hook up are a nightmare to extract. I really don't know what to do. A 35 Ah pack will run between 3 and 4 hundred bucks.

Thanks.

LC. out.

Attachments

markz

100 TW

You can snip the tabs in the middle of the tab so some tab is left to solder to, then figure out your insulation material your going to use whether classic 18650 rings or using 18650 holders and hopefully theres not much overhanging tab to deal with.

DAND214

10 MW

Remember, leaving batteries in the cold cuts capacity like half. Being used than the cold, they don't like that.

Dan

Dan

tomjasz

1 GW

253 pages of ill advised crap builds. Why not build one good ebike?

Chalo

100 TW

tomjasz said:253 pages of ill advised crap builds. Why not build one good ebike?

He has a method! He sticks to it! This is one of the things that separates art from engineering.

Sometimes, the role of art is to make you say "ew".

latecurtis

100 MW

The wheels both need to be trued. They are bad !!!

The axle is really short. I have no room for torque arms or anything else and there is a huge lawyers lip also,

I had these forks put on the front of the Currie a few years back so I could run the disk brakes. I do not want to switch them. That is a deal breaker on this upgrade.

Not sure what I should do. Also I do not have a wrench or socket that fits those axle nuts. It is really odd. Some sort of Chinese bull shit. I am not happy.

I could use some advice on this.

Please let me know.

Thanks.

LC. out.

Chalo

100 TW

Did they send you any tabbed washers? The funky seven-sided axle nuts aren't Chinese BS; they're an anti-theft measure.

Two of the wheels I ordered came with no small parts at all, and the other two came with assorted parts (including disc calipers). Tabbed washers aren't torque arms, but they're a lot better than nothing. They'll fit in your lawyer lips situation, too.

I bought a bunch of SAE 7/16" washers and M12x1.25 nuts to set them up.

EDIT:

I see the tabbed washers now, inside the dropouts. Use SAE 7/16" washers inside the dropouts and the tabbed washers on the outside, and they'll fill in the lawyer lips. That doesn't help you with torque arms for a fork that isn't safe to use without them, though.

Two of the wheels I ordered came with no small parts at all, and the other two came with assorted parts (including disc calipers). Tabbed washers aren't torque arms, but they're a lot better than nothing. They'll fit in your lawyer lips situation, too.

I bought a bunch of SAE 7/16" washers and M12x1.25 nuts to set them up.

EDIT:

I see the tabbed washers now, inside the dropouts. Use SAE 7/16" washers inside the dropouts and the tabbed washers on the outside, and they'll fill in the lawyer lips. That doesn't help you with torque arms for a fork that isn't safe to use without them, though.

markz

100 TW

Need a better picture of the odd axle nuts to see the flat end part of it. Otherwise I'd see if I couldnt take a flat head screw driver to one of the nuts flanged sides to spin it off, be sure to lube it up plenty before hand. Worse comes to worse you'd have to grind in a slot for a flat head for better bite/purchase. Then the last stand would be just cut it off without damaging the axle so cut in then take a flat head and twist it to break the nut/bolt. Yeah whatever that thing is, probably better to call it a bolt then a nut but I aint editing.

Chalo

100 TW

markz said:Need a better picture of the odd axle nuts to see the flat end part of it.

They're seven-sided anti-theft nuts. Replace them with normal M12x1.5 nuts to get on with life.

The thick nasty dropouts on that skanky suspension fork are just as unorthodox as the axle stud lengths.

latecurtis

100 MW

They're seven-sided anti-theft nuts. Replace them with normal M12x1.5 nuts to get on with life.

The thick nasty dropouts on that skanky suspension fork are just as unorthodox as the axle stud lengths.

Yea.

The lawyers lip needs to be dealt with. My grinder and vice grips could cut and grind a washer to fit that but may need a little JB weld so that it is flush. I may need a little sand paper.

That is a start.

I will still need to do a substitute for a torque arm. It will need to fit over new ale nuts. Not sure

it will work eventually.

SAE 7/16" washers and M12x1.25 nuts.

I need to call hardware stores like Ace and True Value . Maybe Home Depot or Lowes.

Thanks.

LC. out.

tomjasz

1 GW

YIKES!!! Here's an interesting deal!

https://batteryhookup.com/products/panasonic-48v-power-module-13s-6-4a-300wh?variant=37417514860706

https://batteryhookup.com/products/panasonic-48v-power-module-13s-6-4a-300wh?variant=37417514860706

Chalo

100 TW

tomjasz said:YIKES!!! Here's an interesting deal!

https://batteryhookup.com/products/panasonic-48v-power-module-13s-6-4a-300wh?variant=37417514860706

Super cheap, high power capacity, and very robustly packaged. 12 lbs for only 300Wh nominal is quite lame, though. It makes me wonder how much of that is the steel case, and how feasible it would be to transfer the cells to another enclosure.

markz

100 TW

Depending on how much thread you have left when a nut is installed then there are a some fixes like grind down a regular axle nut to make it thinner to make extra room for a torque arm.

On my MXUS 3kw motor I had lots and lots of axle length, then on my Leaf 1500W I am kinda of in the same boat as you but I think your axle is much shorter.

On my MXUS 3kw motor I had lots and lots of axle length, then on my Leaf 1500W I am kinda of in the same boat as you but I think your axle is much shorter.

latecurtis

100 MW

As the Hub Motor Turns and the LiPo Fire Burns. I made up my mind what my next motor will be but currently out of stock. Waiting for one of those. They will e mail me when in stock.

Stimulus money is in.

I just hope they are building my motor as I sit here typing. :lol:

- 6 Kilowatts !!!!!!

I might need to order more batteries. Also torque arms. :lol:

Thanks.

LC. out.

Stimulus money is in.

I just hope they are building my motor as I sit here typing. :lol:

- 6 Kilowatts !!!!!!

I might need to order more batteries. Also torque arms. :lol:

Thanks.

LC. out.

Sunder

10 MW

Good luck fitting that to a normal bike without a fair bit of engineering the dropouts and frame... not to mention the size of battery that could both get the performance out of it and have a decent life.

Thought the Greyborgs could do more than 6kw too, maybe it's a different model or under rated.

Btw, with internal anti-theft nuts, most often it'as a joke. Get a screw driver you don't want that's the right size, and you can often catch enough of the edges to get the nut off. If there isn't one, get one a tiny bit too big and file a few tenths of a mm off at a time until it's small enough to fit, but too big to slip.

Thought the Greyborgs could do more than 6kw too, maybe it's a different model or under rated.

Btw, with internal anti-theft nuts, most often it'as a joke. Get a screw driver you don't want that's the right size, and you can often catch enough of the edges to get the nut off. If there isn't one, get one a tiny bit too big and file a few tenths of a mm off at a time until it's small enough to fit, but too big to slip.

latecurtis

100 MW

Btw, with internal anti-theft nuts, most often it'as a joke. Get a screw driver you don't want that's the right size, and you can often catch enough of the edges to get the nut off. If there isn't one, get one a tiny bit too big and file a few tenths of a mm off at a time until it's small enough to fit, but too big to slip.

I am not concerned with removing them. Just replacing them with a nut that is strong but more narrow so I can use my torque arms.

I solved the problem of extracting the cells. I went to Wall-Mart yesterday and nobody there knew what Dremel I needed to go with my cutting kit I bought for 10 bucks. It has a lot of cutting wheels.

I solved the problem by not using a Dremel and threw out the old one I broke. My Ryobi electric drill works fine and I shot a video.

https://www.youtube.com/watch?v=A9ws-9Oqg7E&t=4s

Yes. I will need to buy a lot more cells to power HUBZILLA.

What a beast.

https://www.youtube.com/watch?v=r9ZuuSW-A5U

Thanks.

LC. out.

latecurtis

100 MW

As the Hub Motor Turns and the LiPo Fire Burns. Please watch this video. Is it for real ??????

I am really mad. How is this kid going 44 mph with a 1,000W kit ??????????????????????????????????

How is this kid going 44 mph with a 1,000W kit ??????????????????????????????????

https://www.youtube.com/watch?v=Ik6poNLzswM

Basically most 1,000W kits are geared for 28 mph @ 48V. - Is that correct. ?????

28 mph / 48V = 0.58 * 72V = 42 mph.

OK If the LiPo is 4.15V at full charge then

28 mph / 48V = 0.58 * 74.7 = 43.3 mph.

This is with zero voltage SAG.

My biggest question is how can a 48V controller handle over 70 volts. That makes no sense.

It makes me think that I would not need to spend 500 bucks on Hubzilla as a 48V - 1,500W rear hub motor should do 43 mph @ 56 volts depending on the rpm of a 1,500W hub motor @ 1,500W. And also the amp rating and cap limit on the controller.

28 mph @ 48V - 480 rpm.

600 rpm. / 480 rpm. = 1.25.

28 * 1.25 = 35 mph.

Ok so 600 rpm and 1,500W = 35 mph.

35 mph / 48V * 66V = 40.8 mph.

1,500 / 48 = 31.25 amps.

72 * 31.25 = 2,250W

A 38 amp controller would put out 2,280 watts @ 60V.

38A * 60V = 2,280.

So a 48V controller with 66 or 72V caps should work as long as 38 amps or higher with a 1,500W 48V hub motor right ? I will need 66V for the rpms though so need to look for a 60V controller rated at 38 amps or higher and use with a 48V - 1,500W motor. ???

Not sure if that is correct but please let me know how that kid got 44 mph with a 1,000W motor kit.

Thanks.

LC. out.

I am really mad.

https://www.youtube.com/watch?v=Ik6poNLzswM

Basically most 1,000W kits are geared for 28 mph @ 48V. - Is that correct. ?????

28 mph / 48V = 0.58 * 72V = 42 mph.

OK If the LiPo is 4.15V at full charge then

28 mph / 48V = 0.58 * 74.7 = 43.3 mph.

This is with zero voltage SAG.

My biggest question is how can a 48V controller handle over 70 volts. That makes no sense.

It makes me think that I would not need to spend 500 bucks on Hubzilla as a 48V - 1,500W rear hub motor should do 43 mph @ 56 volts depending on the rpm of a 1,500W hub motor @ 1,500W. And also the amp rating and cap limit on the controller.

28 mph @ 48V - 480 rpm.

600 rpm. / 480 rpm. = 1.25.

28 * 1.25 = 35 mph.

Ok so 600 rpm and 1,500W = 35 mph.

35 mph / 48V * 66V = 40.8 mph.

1,500 / 48 = 31.25 amps.

72 * 31.25 = 2,250W

A 38 amp controller would put out 2,280 watts @ 60V.

38A * 60V = 2,280.

So a 48V controller with 66 or 72V caps should work as long as 38 amps or higher with a 1,500W 48V hub motor right ? I will need 66V for the rpms though so need to look for a 60V controller rated at 38 amps or higher and use with a 48V - 1,500W motor. ???

Not sure if that is correct but please let me know how that kid got 44 mph with a 1,000W motor kit.

Thanks.

LC. out.

markz

100 TW

Video

48V 26A Voilmart front hub is what the video has. Old mtb bicycle, standard 26 wheels, kid probably weighs a buck five.

At the point of tightening the front hub, no mention of torque arms, never seen any in video which is very dangerous!

And that kind of front fork isnt good for ta's.

All he says is tighten the bolts as tight as you can go.

44mph as seen in video with the cell phone speedometer is probably at the bottom of a hill, however in camera footage shows slight downhill but how much downhill before that point, who knows. Without on camera footage of cell phone speedometer would be easily classified as a click bait title stating 44mph.

Remember that you can push those motors to extremes for short periods of time with no consequences of damage.

Which could have meant he showed 48V 26A controller but installed whatever voltage and 50A to ride on camera.... or read next sentence.

Since its a 48V controller, the kid could have also used a 52V or 60V or 72V battery and you'd never know. You dont need a 48V controller to use higher voltages. Just means the LVC of the controller kicks in at 40V no matter what. So he used 48V 26A controller with higher voltages, or used a swapped in a higher voltage controller.

Also, could have been a 3T motor, more rpm per voltage compared to 8T.

Thats the problem with click bait titles.

My best guess is he is riding down a hill, or upped the voltage or any number of other shenanigans like having help from a vehicle to get up to speed then start filming.

48V 26A Voilmart front hub is what the video has. Old mtb bicycle, standard 26 wheels, kid probably weighs a buck five.

At the point of tightening the front hub, no mention of torque arms, never seen any in video which is very dangerous!

And that kind of front fork isnt good for ta's.

All he says is tighten the bolts as tight as you can go.

44mph as seen in video with the cell phone speedometer is probably at the bottom of a hill, however in camera footage shows slight downhill but how much downhill before that point, who knows. Without on camera footage of cell phone speedometer would be easily classified as a click bait title stating 44mph.

Remember that you can push those motors to extremes for short periods of time with no consequences of damage.

Which could have meant he showed 48V 26A controller but installed whatever voltage and 50A to ride on camera.... or read next sentence.

Since its a 48V controller, the kid could have also used a 52V or 60V or 72V battery and you'd never know. You dont need a 48V controller to use higher voltages. Just means the LVC of the controller kicks in at 40V no matter what. So he used 48V 26A controller with higher voltages, or used a swapped in a higher voltage controller.

Also, could have been a 3T motor, more rpm per voltage compared to 8T.

Thats the problem with click bait titles.

My best guess is he is riding down a hill, or upped the voltage or any number of other shenanigans like having help from a vehicle to get up to speed then start filming.

latecurtis

100 MW

He used 6S multistars. LiPo. 4.17 * 18 = 75.06 after voltage SAG = 74V.

Brand new they might have a resting voltage after a full charge of around 75 volts so will go with 74V after SAG,

Yes he broke two sets of forks. :lol:

I remember breaking one set back when I first hooked up my 1,000W hub motor. I was not running 74 volts though but my LiPos were newer back then so probably around 47V after SAG.

I just need to find out what 48V controller could handle 75V input. That is the part that really don't make any sense at all to me.

Perhaps it was a 48 - 72V controller with 76 or 80V caps.

What do you all think about that video ???

DAN ??? SUNDER ??? DA. ????

If I got that kit is could save me a ton of money. Also if I could get a 1,500W motor with a bigger Stater I should easily get > 40 mph.

This guy did 50 mph but was > 80V.

https://www.bing.com/videos/search?q=1500w+hub+motor&docid=608053802069065914&mid=86E1737E9605D4ACFEBD86E1737E9605D4ACFEBD&view=detail&FORM=VIRE

please let me know.

Thanks.

LC. out.

Brand new they might have a resting voltage after a full charge of around 75 volts so will go with 74V after SAG,

Yes he broke two sets of forks. :lol:

I remember breaking one set back when I first hooked up my 1,000W hub motor. I was not running 74 volts though but my LiPos were newer back then so probably around 47V after SAG.

I just need to find out what 48V controller could handle 75V input. That is the part that really don't make any sense at all to me.

Perhaps it was a 48 - 72V controller with 76 or 80V caps.

What do you all think about that video ???

DAN ??? SUNDER ??? DA. ????

If I got that kit is could save me a ton of money. Also if I could get a 1,500W motor with a bigger Stater I should easily get > 40 mph.

This guy did 50 mph but was > 80V.

https://www.bing.com/videos/search?q=1500w+hub+motor&docid=608053802069065914&mid=86E1737E9605D4ACFEBD86E1737E9605D4ACFEBD&view=detail&FORM=VIRE

please let me know.

Thanks.

LC. out.

Attachments

markz

100 TW

Controllers have capacitors inside them, they usually are always the same voltage capacitors like 60V for 52V and under controller, so with a 48V pack thats 4.20V x 13 = 54.60V so plenty of room to spare for 48V controller with 48V battery fully charged to 54.6V and 60V capacitors. You could probably get away with a 14S pack or 52V pack voltage of 58.80V fully charged. I am actually using a 36V controller with 52V pack (from Grintech, has its own BMS for LVC, would never do the same with a battery pack with no BMS to cut off) because the controller has 60V caps, I am not sure what the other default voltage ratings are for capacitors, maybe they are set or maybe different manufacturers have various values. You dont know unless you open up the controller and look. So lets say for example a 60V or 72V controller might have 100V caps inside them.

Here is a screen shot of mouser.com for every capacitor type. Not sure what the name is for the type of capacitor the barrel blue ones are, maybe Aluminum Electrolytic Capacitors - Radial. Easy to change out, way easier then mosfets!

Easy to find out what type of caps they are I just randomly saw a pic on mouser.

This may help, think I'm right.https://en.wikipedia.org/wiki/Capacitor_types

What the generic controller makers use is another story, cheapest they can find.

Here is a screen shot of mouser.com for every capacitor type. Not sure what the name is for the type of capacitor the barrel blue ones are, maybe Aluminum Electrolytic Capacitors - Radial. Easy to change out, way easier then mosfets!

Easy to find out what type of caps they are I just randomly saw a pic on mouser.

This may help, think I'm right.https://en.wikipedia.org/wiki/Capacitor_types

What the generic controller makers use is another story, cheapest they can find.

Chalo

100 TW

Capacitors are not the only voltage rated parts in there. FETs are also confined to a maximum operating voltage. I don't know if there are others.

latecurtis

100 MW

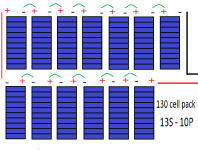

That is the pack I am building.

If these cells I am removing were not already 3S intact. I would be creating 1S - 10P by soldering 10 - 18650 cells in parallel and just wiring 13 of them in series and charging at 1S - 2 amps.

I would charge up a ton of them ahead of time and hook them all up in series before running them.

Thing is these packs are 3S and tried to break one apart and did not happen. They are glued together so decided to build 13S packs like the diagram for now.

I will be buying and building huge packs as planning on running 3 kilowatt motors and exceeding 40 mph.

I am just wondering if all that balance charging would be necessary. Could I charge 1S - 10P and just hook them in series with bullets and charge each separate ?????????????

I already ordered 20 = 6S balance plugs. I just don't want to solder all those wires. I would rather try to break apart all the 2S packs breaking the series connections and build 1S - 10P and repeat that for all the cells I have as well as a ton of future cells.

Please let me know which would work better ????

Thanks.

LC. out.

I am talking 400 or 500 cells. Maybe more.

I might just order a third charger or some cheap 1S - 1 or 2 amp chargers if they have them. I could always be charging 3 or 4 - 1S packs awhile at home and just hook bullets to positive and negative for series connections.

It would be simple and a lot less work. charging 1S - 10P is faster than 6S - 1P ???????

60 cells each. Two could do 120 cells and my two 6S chargers could each do 1S - 10P so 14S with 4 chargers would work.

https://www.ebay.com/itm/Turnigy-UP-S6-Lipo-LIHV-Smart-Charger-for-1S-Batteries/293485797405?hash=item44551de01d:g:wj4AAOSwYzdeTplP

http://prntscr.com/wgp5jp

Please let me know.

Thanks.

LC. out.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 27

- Views

- 767

- Replies

- 16

- Views

- 1,821

- Replies

- 31

- Views

- 2,976

- Replies

- 0

- Views

- 191

- Replies

- 28

- Views

- 1,851