Yes it is fun. Been doing my own thing like 8 years now. I love experimenting. Those small motors are cool. I have a lot going on. I have a Giant Cypress 700c hybrid that has 21 perfect pedal gears. It had a 700c e bikeling geared hub motor on the front but moved it to the front of my 700c Giant Roam.

That Giant Cypress hybrid is perfect for experimenting on the front with those small RC type motors. Not sure about 6 and 40+ mph but perhaps two or three and 30 mph. I want to keep that bike light for pedal.

The 1,800W brushless motor on the 20" tire with the flat tire was cutting out last time I run it under load. I need to find the cause, If it is battery or controller. I might decide to strip it. Remove the 1,800W motor and controller and put it on a shelf for a future project.

Then I can order two 36V - 1,000 watt 3,000 rpm brush Unite motors exactly like what is on the back of the Currie now. One on the front and one on the back of the 20" bike. Two brush 1,000W controllers at least 30 amps. 40V * 30 amps = 1,200W - Perfect. A single thumb throttle like what is on the Currie set up. One throttle two controllers. 40 mph gearing and 2,400W total power.

However I need to get back to the LIFEPO4 subject. I am about to eat dinner. Yea it is 10:30 PM. I sleep until 5 or 6 PM most days. I will be posting after that about 30 minutes.

7/12/21

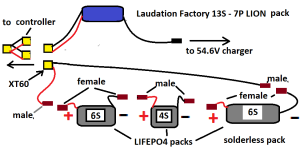

Yea. That is just more than a little ridiculous for one e bike. Five battery packs !!!!!!!! (top pic) That is what I would need for the 26" dual suspension. The LIFEPO4s in parallel with the 13S Lion and then a 10S - 8P pack which may be defective. I can not do it.

I will reluctantly need to dis assemble the solderless 6S LIFEPO4 pack and build it exactly like the one in the smaller black hyper tuff storage box with the handle. It is not much larger than a 22 AH SLA and kind of looks like one. It takes up less than half the space of the solderless pack.

The bottom pic shows the Diamondback I am not using. I could take the 1,000W motor off the 26" dual suspension and put the 1,800W brushless motor on the back and put the 1,000W hub motor on the back of that Diamondback if it will fit. I have to haul it up stairs anyway as I need to hook up the sensor less 1,000W 35 amp Greentime controller anyway.

I also have that 750W gear reduction motor laying around. I could take the Bafang off the front of the 26" dual suspension and put the 36V - 750 watt gear reduction motor on the front. A 2 kilowatt controller for the 1,800W brushless motor and 1 kilowatt 30 amp 48V brush controller for the front. Total power will be > three kilowatts @ 53V and will run off a single throttle with 50 mph gearing.

Unfortunately I do not even have a reliable > 1,000W 53V pack let alone a 3 kilowatt pack. The 13S 7P pack is questionable. I know it wont do 1,200W Looking at = or < 1,000W

So that might be a pipe dream. I have not hit 30 mph with that pack yet. Close though. Was going to put the camera in front of the meter but then had the voltage drop and flat tire.

However I am still looking for feedback on the LIFEPO4s and the parallel hookup to the 13S - 7P pack. I might have to re solder all those LIFEPO4 to install heavier gauge wire but do not want to. I got too many other things I could be doing so will repost the video and my wiring diagram now as was hoping to hear from DA. If the parallel deal will not work safely I wont be running LIFEPO4 any time soon.

https://www.youtube.com/watch?v=x8sM3geHB3M

I am hoping DA will watch the video link above the diagram and then look at my diagram and then give his professional opinion. I actually started a new post here on ES and got feedback from a member I never saw before. However I highly respect DAs opinion as he went to college I think for electrical engineering and think he got his masters. If DA reads this I got this information from my new post.

by batteryGOLD » Jul 12 2021 4:21pm

U could get more capacity from this system by charging all this stuff to 57,6V , but...

you have to MAKE SURE that Lithion ION 13S BMS cutoff/opens circuit at 54,6V!

this way, since LithION battery is full, it keep putting more charge at LiFePO4 packs until max 57,6V

NOT recommend doing this..

if LithION pack bms does not have superior cutoff,it will put 57,6V at lithION 13S cells, meaning 4,43V for each cell. maybe still workin..

by batteryGOLD » Jul 12 2021 4:01pm

That crazy system will work fine but tricky.. take care about voltage limits details!

usefull total voltage range for this parallel working range --> 54,6V(upper lithium ion cells charger) to 40V (lower LiFePO4 cutoff voltage)

LiFePO

Minimum -->2.5x16S = 40V cutoff

Maximum --> 3.6Vx16S= 57,6V max

LithIon

Minimum -->2,7Vx13S= 35,1V cutoff

Maximum --> 4,2Sx13S=54,6V max

54,6V max voltage limited by lithium ion top limit

system cut off LiFePO4 @40V and after that maybe only 13S lithium battery keep drain solo until 35,1V ..

at math is minimum multiple common calculation..

TAKE CARE because is a parallel, LithIon battery will force LiFePO4 voltage to be tha same, if your LithION battery goes 35,1V, so there will be this voltage at LiFePO4 battery package(minimum 40V forced to 35,1V)

make sure LiFePO4 BMS will cutoff/open circuit for sure at 40V! otherwise, LiFePO4 pack will be discharged until 35,1V means 2,19V per cell (under 2.5V lower limit but maybe still safe..)

there is also an unknown behavior at Lifepo4 bms cutoff voltage limits, because x3 serial LiFePO4 batteries. since each of 3 batteries have individual bms. three serial bms's(serial bms's not recommended..) .. it would be more stable if use a single 16S LiFePO4 BMS..

think about this "boom"

make sure LiFePO4 BMS will cutoff/open circuit for sure at 40V! otherwise, LiFePO4 pack will be discharged until 35,1V means 2,19V per cell (under 2.5V lower limit but maybe still safe..)

Yea. The guy sounds like he knows a lot but he failed to read my posts as he thinks the LIFEPO4 has a BMS. Only the Lion pack has a BMS. The LIFE packs have balance plugs for each pack.

I am sure DA has his own opinion but after reading that was thinking if I use the power meter and can monitor standing and voltage SAG onboard I would be able to stop running the packs at any voltage I desire so could avoid running them low and LVC and all of that. I could run from full charge and stop at 46V for example. I am looking for a different power meter with a larger brighter screen though.

The video clearly states two batteries of different capacity in parallel will keep the same voltage during discharge. The 13S - 7P pack is rated at 20 Ah. The 16S LIFEPO4s are rated at 19 Ah. The standing voltage should be really close also if I am charging both the LIFEPO4s and the 13S-7P Lion pack thru the Lion packs charging port with the 54.6V charger.

I do not see any problems but am trusting DA to make up my mind. I do not want these packs to fail or an onboard fire. The LIFEPO4s were about $230 and the 13S Lion pack about $170 so $400 worth of batteries here. What I want to do is not simple. It is complicated unorthodox. It is not the LIFEPO4 cells I worry about as they are almost indestructible compared to Lion. It is the 13S Lion pack and what the BMS will do.

It seems though if the LIFEPO4 is being charged with the same 54.6V charger that the Lion 13S BMS will just see it as a 54.6V load and after charging there should be minimal current flow between the packs to equalize everything. I might have to use the balancer though to balance the LIFEPO4 if the packs become unbalanced as no LIFEPO4 BMS.

I have three balancers so is it ok to balance the three LIFEPO4 packs while charging or need to split up the packs and balance before charging. Is it ok to Balance the LIFEPO4 packs awhile in parallel with the Lion pack ????? I know balancing will lose some voltage as it goes from the highest cell down but then the 13S Lion pack should add that back to the LIFEPO4s and it would all equal out. I just do not know. I am just guessing.

If charging them separate and balancing the LIFE when NOT in parallel with Lion I just need another 54.6V charger. Probably a better idea as then it is less complicated. ??? They will discharge together and charge and balance separate.

I hope DA posts.

Thanks.

LC. out.