owhite

100 W

- Joined

- Aug 3, 2020

- Messages

- 285

It depends how much power you're running, but you should definitely look up the power rating of a 8m belt at that width, I doubt it's capable of carrying the torque that these motors are capable of.

you make a good point (and your user name definitely checks out)

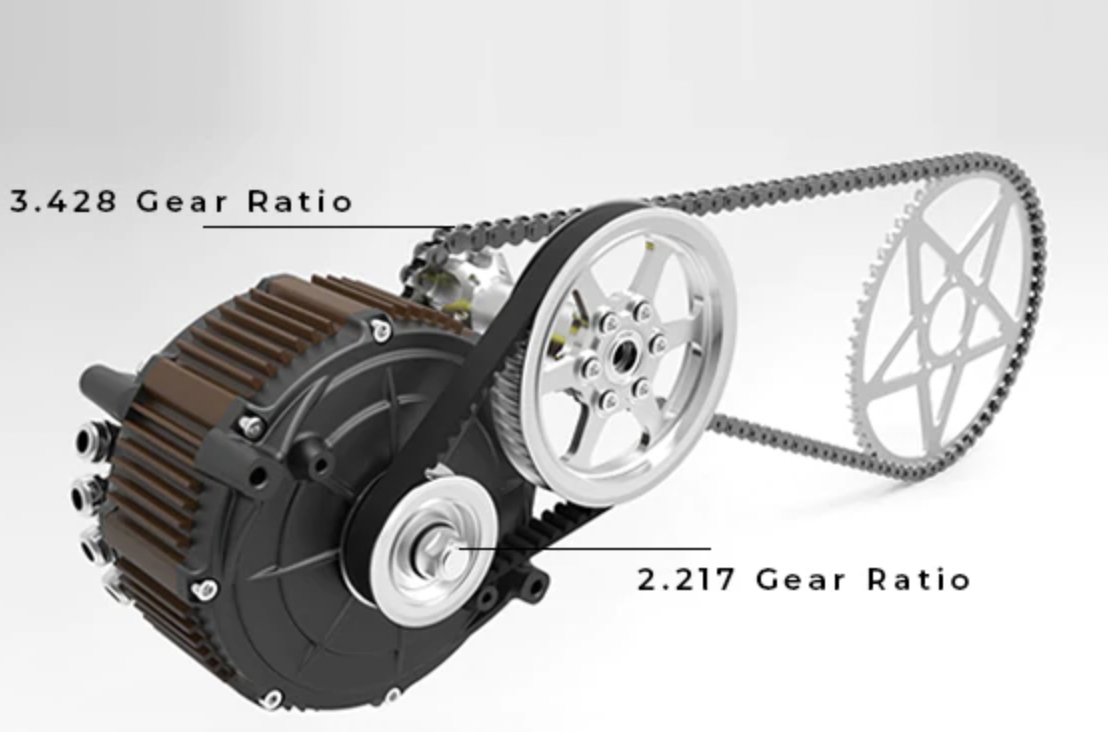

The motor is designed to be a drop in for the surron, which uses a two stage gearing system:

So I assume we have lower torque on the input side of that gear box, which is fine for that size pulley/belt, but it's not a good match for a direct drive system to back wheel.

This would be a compelling reason to lose the pulley and put on a metal sprocket. That would also allow to use smaller teeth so the back sprocket doesnt need to be as large as originally calculated with the existing belt drive.