Thanks for the posts about my situation folks. Regarding a few responses about my technical abilities or knowledge... I guess it's a good thing that I don't feel like I need to explain myself, and those reading, also don't really care about my explanation. We're on even ground of not giving shits about each other, which is a nice place to be :lol:

The truth is, I'm not an electrical engineer (I hit triangles with calculators for a living), and I've got enough on my plate between racing spec miata, desert moto racing and mountain bike racing... I did the sensible thing and hit the easy button and ordered from eco-ebike on this one. The cost was marginally more then I would have spent procuring all of the different parts from different places and it showed up pre-installed. It's not that I'm not capable of doing the work... It's that this was a logical way to get the right items in a timely manor.

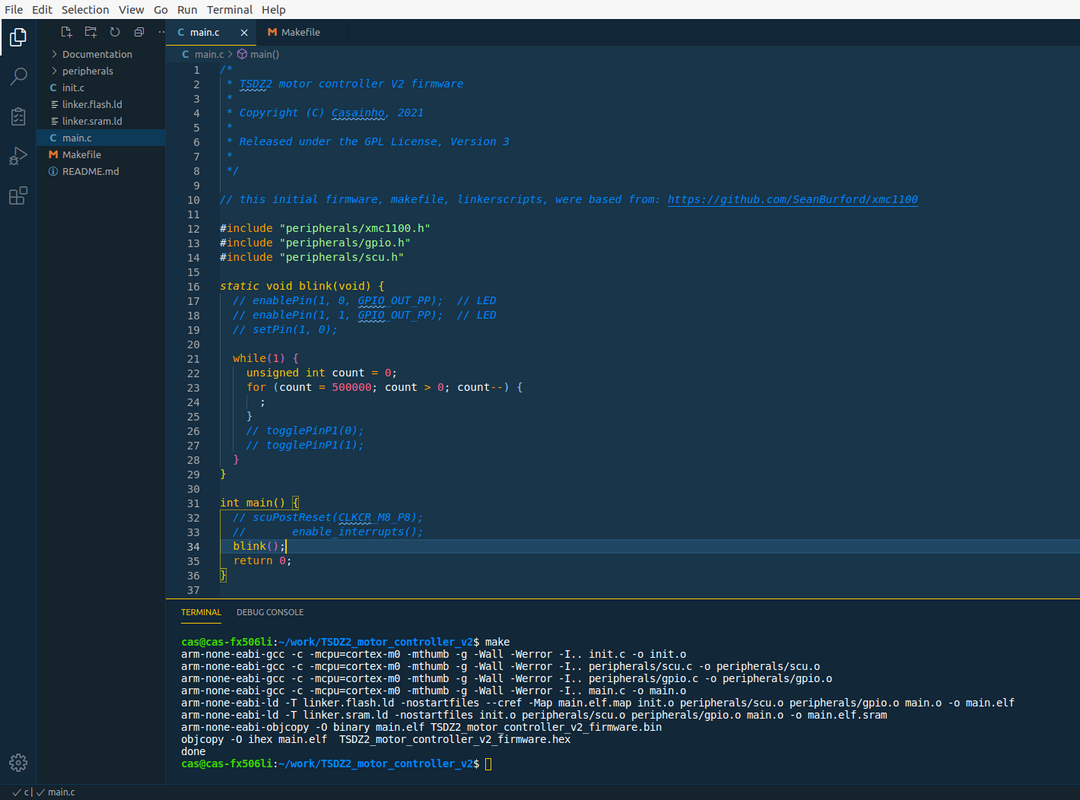

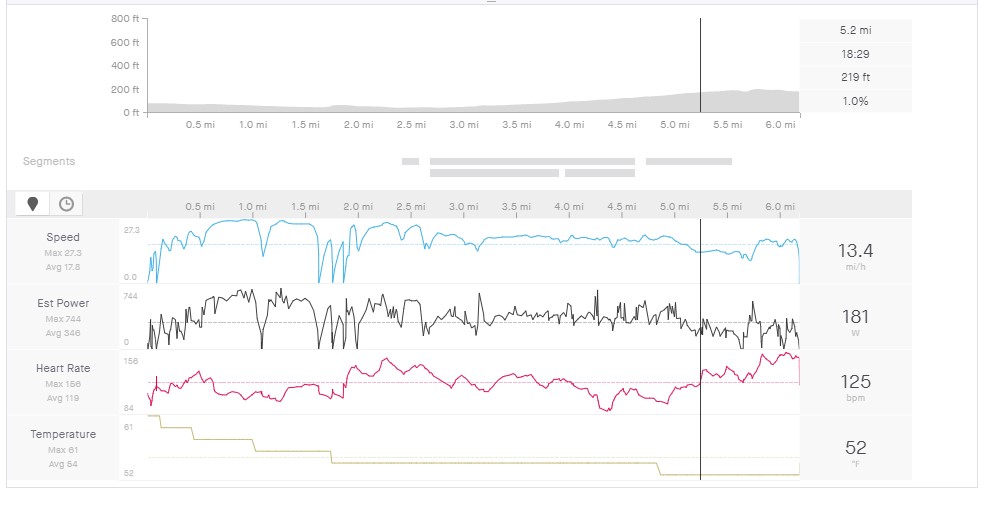

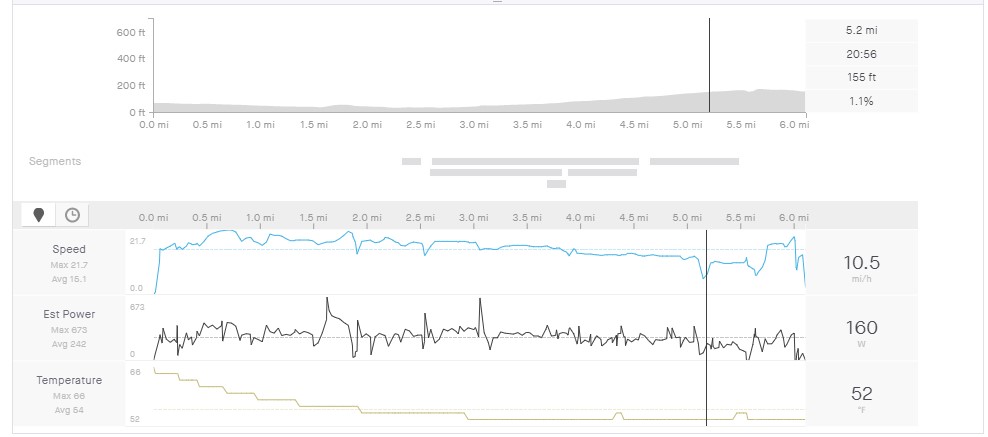

So... Regarding the testing I had done... I did 3 commutes to work to hash out this issue. The first ride I did was at assist level 12 and I largely let the motor do it's thing and didn't pay that much attention to the wattage output of the motor. This was my first work commute and the motor went into thermal throttling at mile 5.1 - 5.2 and hit 180 degrees.

You can see that point by the line/mark in the graphs where my heart rate climbs quickly. This is when I shut the bike off and just pedaled pretty lightly.

The next work commute I did on the same route, I payed much closer attention to the heat/output of the motor. I kept it in assist level 7, and made sure to keep the motor pretty much at the 250-300w mark, except for pulling away from the 2 stoplights I hit. This ride was extremely perplexing because it started to reach thermal max at mile 4, and by mile 5.1, it was at 180 degrees. Same exact ride, same ambient temperatures.

So far, the following potential causes for this have been floated out there:

1) My inability to own and operate this motor correctly. While possible, this seems unlikely to cause this motor to overheat at assist level 6 after 15 minutes

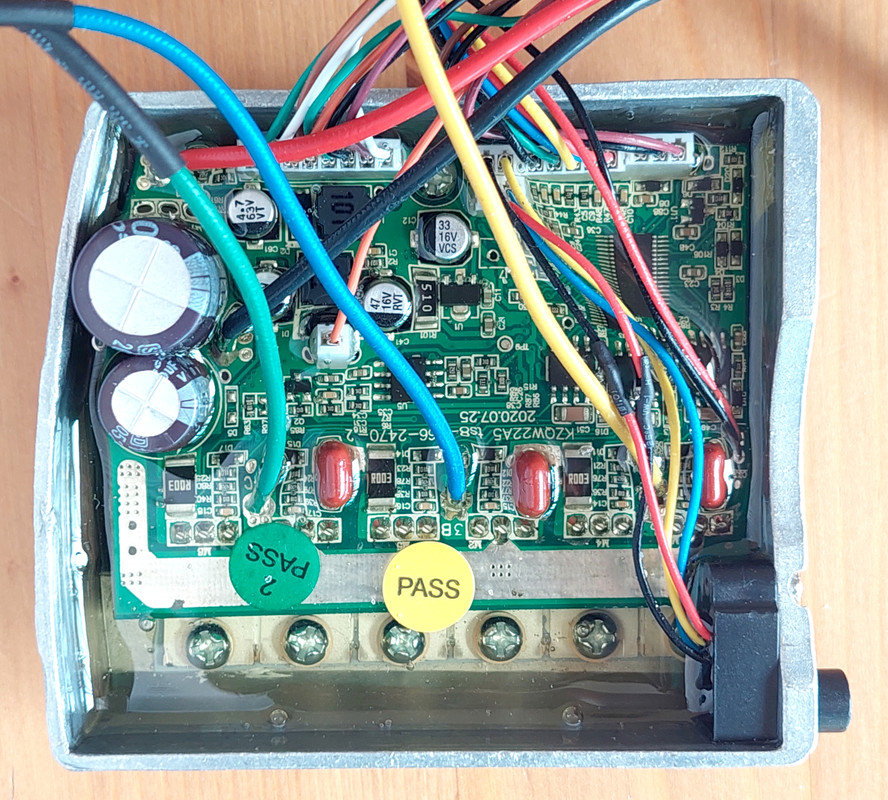

2) Some issue with the current firmware, potentially related to field weakening. Again, seems unlikely, but possible. :|

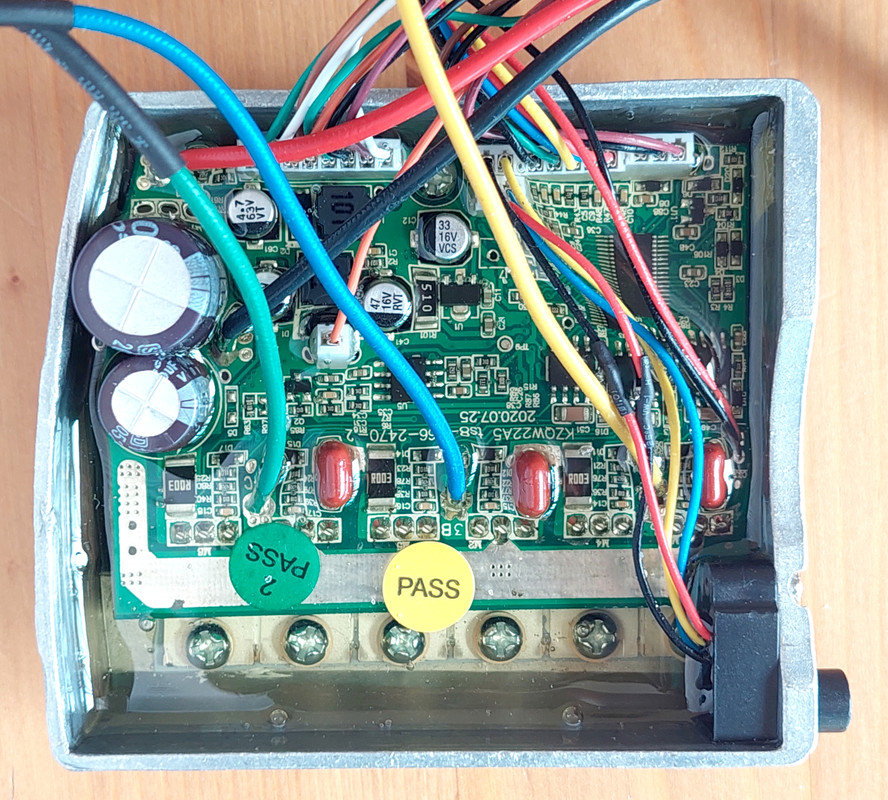

3) An issue with my particular unit from a mechanical perspective :?

4) An issue with a sensor on my particular unit, temp sensor or otherwise :x

5) A mechanical issue with the bicycle, at this point I'd say this one is dead as I've gone through everything

So... It seems the next steps are the following

1) Reflash to stock firmware. I'm not 100% sure what this will do other then validate that the motor could output power at assist level 6 without overheating. The problem is, I won't know if it's overheating and there won't be a temp sensor reading.

2) Reflash with a previous version of the OSF.

3) Return the unit to Eco-Ebike for them to QA/QC or replace

4) Tear the unit down and check it myself and add any thermal modifications needed.

I still have a few questions:

1) David from eco-ebike has suggested that the field weakening and a high cadence can generate heat faster with the OSF. Does anyone here see any logic to that and are there specific parameters I should be looking out for when riding to avoid this? IE, keep cadance below 90, make sure motor RPM is in window XXX-XXX etc?

2) Is field weakening alone, what is allowing the motor to run higher RPM then the stock firmware, or are there other contributors. I've read about Field Weakening, and understand it generally when it would come to an archaic DC motor... but I'm afraid I'm a bit over my head in 3 phase brushless motors... although I'm drinking from the fire hose of knowledge. My assumption at this point is that field weakening is the electric motor equivalent of retarding and advancing ignition timing on an IC engine, and that there is likely a point of no return in here that may be contributing to my problem.

3) How much resistance should I feel when pedaling the bike in the work stand with the system off? I don't really have a great gauge for what this should feel like, but my only comparison is an x01 eagle drivetrain, which is quite efficient in comparison. Anything basically feels like pedaling through molasses compared to that.

So... I think the best next steps for me here are to try and previous version of OSF, and define a specific route that is repeatable. I need to figure out what the best way to data log the motor output so I can analyze that data. I could just point a gopro at the 860c display, but there has to be better way then things.