gfmoore

100 W

raylo32 said:No, that sounds about right. Remember the 48v is your nominal battery rating, whilst full charge for a li ion cell is ~4.2v... so 4.2v x 13 cells = 54.6V.

Ahh, thanks.

raylo32 said:No, that sounds about right. Remember the 48v is your nominal battery rating, whilst full charge for a li ion cell is ~4.2v... so 4.2v x 13 cells = 54.6V.

gfmoore said:gfmoore said:smalldisplay.png

I'm still trying to find answers from the entire internet on what settings I should have?

Poles in motor = 1 doesn't sound right? More like 6 perhaps. However, I don't want to damage the motor (anymore than it might be?) by just changing numbers at will!!!

casainho said:

raylo32 said:Very cool. To make it a real beast for cargo how about adding a second bottom bracket and timing chain like on a tandem just without pedals, and a second TSDZ2? That would pull a load. Although it might be hard to synchronize their outputs unless somehow run off one controller.

casainho said:

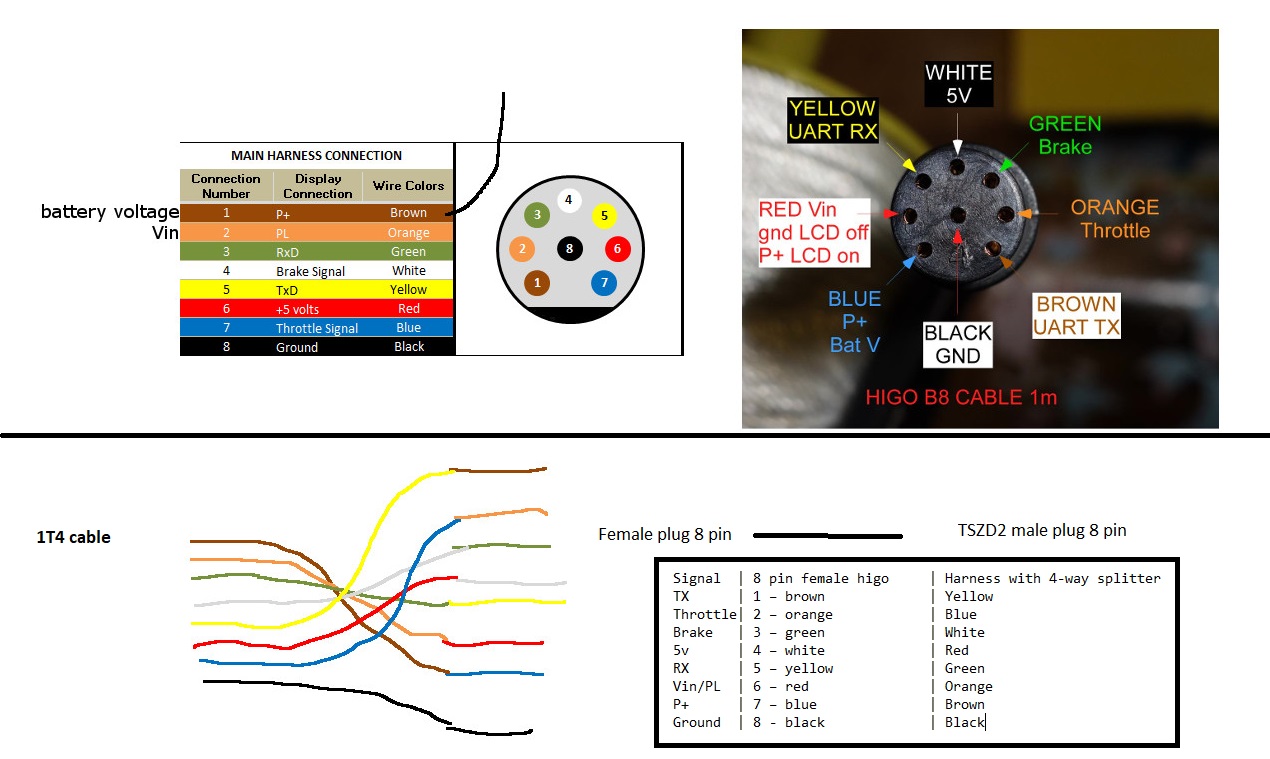

raylo32 said:Here is the Bafang wiring chart. If you don't have e-brakes you may have a version of the harness cable that omits the brake connectors. I believe they make the harnesses in several versions, T-1( to display only), T-2 (display and throttle), T-3 (display and e-brakes) and T-4 (all of the above).

BBS_wiring.png

seattlesockey said:Attempting to update display using APT boot loader w/ Silicon Labs CP210x USB to UART Bridge COM 3 driver. But keep getting "This device cannot start. (Code 10)". Worked before on MS Surface tablet (as recently as March 2021). Tried uninstall/install multiple times with same result.

Hoping someone has an idea what's wrong and how to fix it.

skestans said:sysrq said:Looks like finally devoped some thin crack in the plastic cover above the pinion gear due to friction caused by chainring. Probably one of the solutions is to move the chainring outwards by a millimeter and glue some piece of plastic above the crack.

Another option would be plastic welding.

J-B Weld PlasticBonder is said to be slightly more flexible.

Or maybe just use some oil resistant silicone adhesive from the other side, so that in case it falls of it won't damage anything compared to epoxy.

I would get a replacement cover. They don’t cost much (I think I paid 15$ delivered for mine on aliexpress) and then you don’t have to worry about whether the plastic is properly fixed or whether water/grime will seep into the main gear chamber.

gfmoore said:Somehow I need to splice what I guess is a 8 wire cable to the motor. Does anyone know of a link to how to splice my display cable or what the pin outs/colours are so I can try and add a brake cable - or perhaps even better a link to where I can get an appropriate cable. I couldn't see anything on ebay or aliexpress, they were all the type I bought. I must admit I don't really want to splice, but if that's what I need to do...

Note: I've just checked and the connector from the motor is an 8 pin male (centre pin) (plus the speedo sensor cable)

Which FW version? Stock or OSF?Pooyan said:I have a problem with my VLCD5 8 pin display, since yesterday it is showing EO4 on the screen, throttle error.

....

Anybody a tip how the solve/remove the error code?

What's the backlight color on Enerpower 500S-U? Probably white? Had to swap out the SMD diodes in VLCD6 for dimmed down orange ones in order the achieve better distance vision and reduce eye fatigue (blue light tends to scatter in the eye).JohnAnanda said:Mr.Flibble said:JohnAnanda said:Has anybody tried the Enerpower 500S-U TSDZ2 compatible display ?

It looks like an interesting alternative to the VLCD6, and it has a 500mA USB charging port.

https://enerprof.de/en/motor-kits/d...0s-u-display-uart-tongsheng-compatible?c=234/

That's a Bafang 500c display.

It's supposed to be really nice.

The case looks almost identical to the Bafang color 500C display indeed, but this "500S-U" seems to be monochrome and Enerprof sells it for almost 20€ cheaper than the 500C. I wonder if it's a 500C that they flashed to make it compatible with the TSDZ2 (in this case it seems weird that they would sell it cheaper than the original 500C). I'm tempted to get one to see if it would work with the OSF for stock displays..

Elinx said:Which FW version? Stock or OSF?Pooyan said:I have a problem with my VLCD5 8 pin display, since yesterday it is showing EO4 on the screen, throttle error.

....

Anybody a tip how the solve/remove the error code?

E04=Throttle issue is for Stock FW

For OSF:

E04= ERROR_MOTOR_BLOCKED

Motor or wheel blocked, excessive current absorption without motor rotation.

Check the cause. After 10 seconds the error disappears and the bike can be reused.

sysrq said:skestans said:sysrq said:Looks like finally devoped some thin crack in the plastic cover above the pinion gear due to friction caused by chainring. Probably one of the solutions is to move the chainring outwards by a millimeter and glue some piece of plastic above the crack.

Another option would be plastic welding.

J-B Weld PlasticBonder is said to be slightly more flexible.

Or maybe just use some oil resistant silicone adhesive from the other side, so that in case it falls of it won't damage anything compared to epoxy.

I would get a replacement cover. They don’t cost much (I think I paid 15$ delivered for mine on aliexpress) and then you don’t have to worry about whether the plastic is properly fixed or whether water/grime will seep into the main gear chamber.

Can't think of anything better than a correct size silicone seal from the inside and a 5 mil UHMWPE tape from the outside. Just needs to be secured sufficiently. Making a new separate cover only above the pinion gear attached using the same screws holding the plastic wire cover would be too finicky and unpredictable due to constricted space, etc.

Pooyan said:I have a problem with my VLCD5 8 pin display, since yesterday it is showing EO4 on the screen, throttle error.

No throttle attached to the bike, it rained yesterday and i left the display on the bike. I detached the plugs and tried to dry the connections with a hairdryer but the error is staying in the screen.

The remote panel is responding when i press a button, original firmware.

Anybody a tip how the solve/remove the error code?

beemac said:I followed this to splice my original T4 cable:

raylo32 said:If it works with the throttle but not with pressure on the pedals it sounds like your torque sensor may not be working. One way to check is to install the Open Source Firmware which along with the 850C or 860C display allows you to calibrate the torque sensor, during which you will be able to see that it is working from the readings on the screen.

Nowadays there are a lot of software development and I bet there are many users that do that professionally, so I do not understand why there are almost no developers - the firmware is OpenSource, the displays are kind of cheap and the development tools are really cheap so I wounder why there are almost no more developers....g4eml said:Is there any technical reason why the bluetooth support in the SW102 firmware was never completed? (it is commented out in the code). Or was it just a case of too many other things to play with?. I have tried to find some refence to it on the forum but it is not easy to search through over 300 posts.

Having just finally decided to load the OSF on my bike I was a little disappointed to find several bugs still present in the SW102 firmware. (the main one being the assist levels didn't display correctly when using Imperial units. The 0-20 Assist levels were being being treated as KMs and therefore were being converted to 0-12 Miles!)

I have installed the toolchain and fixed that bug but in the process I noticed the Bluetooth support seems to have been started but never finished. I know the wireless display development has taken Bluetooth in a different direction but the SW102 should be perfectly capable of providing basic Bluetooth support.

If there was a technical reason why it was never finished I won't waste time looking at it myself.

Colin.