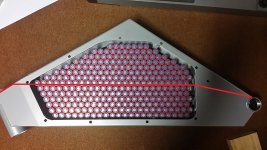

EDIT: made battery count mistake, I thought I had 240 cells, but in pictures it is actually 270 cells. I can get 274 cells in the frame if packed together. There is still room around the edges for some balance wires.

Finally got my frame today. Very nice, it actually exceeded my expectations and they were very high for this frame. It is much thinner than I expected. Build quality looks to be extremely good as normal with Qulbix frames and frame is very light. Looks like Qulbix tried to shave weight off this even more than the weight savings in the raptor 140.

Makes my now obsolete Raptor 165 look like a beast in comparison. The 165 is without doubt obsolete in that it is heavy and bulky, the 140 and the Q76R they went to great lengths to cut down on weight. That being said I took my Raptor 165 out for a hard ride and maybe last ride today and it still rides amazing and is extremely comfortable. I'll have to see how comfortable the Q76R is because it will have a much more narrow seat.

This build I want it to be about 30 lbs lighter, but with the same power and 30% more battery capacity compared to my raptor 165. From my calculations it should be possible. Raptor 165 = 135lbs Q76R hopefully 105 lbs.

The silver color is also a very nice color, I like it a lot more compared to white.

I placed 240 18650 cells inside the battery compartment and it fits nicely, with a little room around the edges also. I was getting a little worried if I would fit the 240 cells, but they fit. Could probably fit a few more, but that is about it. If you got creative you can fit cells in the front of the bike.

It took forever to just line up 240 cells, I can imagine the hours it will take me to build and weld the pack.

The sticker color got mixed up somehow, I may not have been clear so my fault. But I got all yellow stickers, I wanted yellow where it said Q76R and white where it said Qulbix, like the one in the picture they have of their silver bike. Oh well, I can always get these. I guess I'll have to see how the all yellow looks.

I had the head tube reduced by 10mm at the top. Looks fine. I recommend this to anyone planning to use forks like the Marzocchi 888 because without this the 150 mm is too long and you will have to go past the min / max lines on the fork. Also gives me some extra fork adjustment room when I use big 26"x 3.00" tires.

Without doubt, in my opinion, this is probably the best frame out there right now for a thin bike. Best if you want the bike to pass as a bicycle which is important for me. 18650 cells are also the way to go right now and the technology is there to use such a thin frame and get high power and capacity. Thin is in now.

240 Sanyo 3500 MAH cells inside frame

I also got a bicycle seat in black.

It is so much thinner than my Raptor 165. Looks to be like 1/3rd the width. Can't believe I'll fit a 3KW pack in that, when my Raptor 165 only has a 2.3 KW pack.

Head tube cut at top by 10 mm. Looks good.

Thank God I won't have to deal with Lipo Packs anymore.

Thank God I won't have to deal with Lipo Packs anymore. Look at that mess, took me ages to remove the pack for service.