Reid Welch

1 MW

Hi Zoot!

Good points, all noted and well-taken here. Although you are not speaking specifically of this pack installation,

I'd like to note for others who wander into this page:

=The pack is not epoxy potted (nor did you imply that it were so-treated).

It is only double-wrapped now with an added layer of super-quality duct tape (that Gorilla brand stuff).

Prep for that step: the pack was scuff-rubbed with steel wool and then super-cleaned with wipings with isopropyl alcohol,

to ensure best bonding of the Gorilla brand tape. The tape applied, was then rubbed, rubbed, rubbed with a pressing cloth

between a warm, small footprint sealing iron, to fully melt and bed the thick adhesive of the new tape, to the OEM cheap quality duct tape. This, for water sealing, as too, the corners and wire exit points were also sealed with Perfect Glue (silicone)#1.

=Now, the cementing of the pack into the basket should be more or less permanent, yet, reversible if the pack

should ever need to come out. To remove the pack: I'd invert the bike for several days and see if the RTV begins to lose its grip to the scuff-rubbed bottom of the taped pack. If not, then I'd flood the area with mineral spirits or naptha, which will weaken the RTV and allow the pack to be removed (with that gravity assist of fifteen pounds of upside down PING battery.

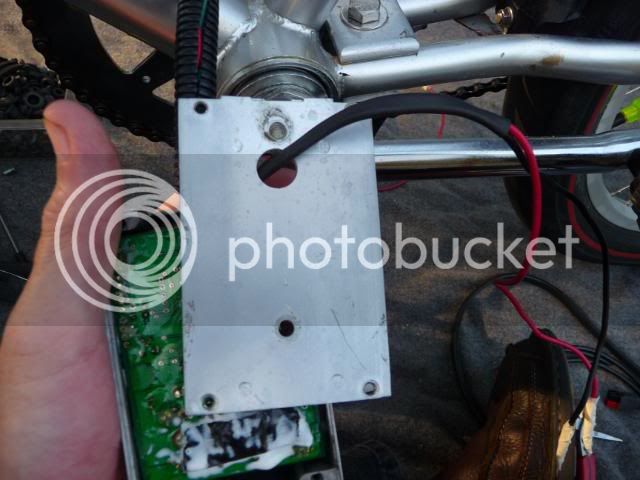

The BMS is the only portion fully epoxy encapsulated. It is a non-servicable part, should it ever fail, yet can be swapped out easily enough if it were to fail.

The plug connector to the BMS can be disconnected in situ, which will allow manual checking of cell balances at any time in the future: that is, I can tell if ever a cell goes bad.

This type of battery is not prone to cell puffing, but if a cell were to puff at all, visual examination will reveal that fact,

and the battery pack then removed and sent in (or serviced by myself) to replace any bad cell.

------

Center of gravity: a basket mount battery pack is not ideal for nimble handling;

but then again, neither is a rider sitting tall above the saddle in non-aero stance.

Advantage of this mount: the bike still looks like a ho-hum, uninteresting single speed bike = less curiosity raised in onlookers and thieves, etc.

It will pedal normally, freewheel as any normal bike, and with its coaster brake freewheel: dead silent whilst manual pedaling/coasting.

The weight at present is sixty five pounds. The range of this 36V, 20Ah, geared front hub motor bike (no front brake)

has yet to be determined.

The fore-aft weight distribution is heavily biased to the rear, especially as it is now a sort of "crank forward" bike.

This will limit traction on wet roads or uphill climbs in mud. The only uphill of note around here is a century old rockpit

a couple of blocks away: grassy, a park now, it will be fun to bomb down its steep sides (the half city block park is about fifteen feet deep, with sloping sides all round of about 1 in 4 grade: I expect front wheel slippage when climbing out if the grass is wet.

But most all my riding will be on normally dry, paved, level roads. Headwinds, on occasion, will be the only real load against the bike;

that, and wind resistance to be expected when going more than about 15 mph.

But this is a 20 to 25mph bike.

I may want to exchange the present rear wheel cog for a smaller tooth count for easier spinning when I cover distances at 20mph or greater;

the start-up torque of the eZee will take care of the difficulty of starting off from a standing stop, as at a stop sign, etc.

I plan to use the assist for starting and for long distance, relatively high speed cruising.

I plan to leave the car at home and use the bike for local errands, with plenty of mileage range available

in case I really want to go somewhere...and yet, be able to pedal manually back home without difficulty....so long as there's no headwind.

Living in a flat area really simplifies this bike design. I just don't need multiple gearing: the assist function sort of takes there place (because we have no hills).

IF I lived with various slight to moderate grades, as most of you have, this cruiser concept would not be so nifty.

But as it is, I think I have an ideal formula for my needs: a bike that still looks all-bike without odd additions which only

put off the general public against wanting an ebike.

A year from now all this will be obsolete, as ebikes for light duty already are on the market, looking as bike-like as can be;

but will they go as far and as robustly as this all-steel bike?

I plan to hop curbs with ease (so little weight at the front of the bike) and take air as much as possible

and never break a spoke or bend a rim: Big, soft, Big Hanks, 2.5" are my primary shock absorbers.

The chainwheel has already been exchanged from a 48T (I forget) to a 52T, the largest readily available.

The bike trailer is ready too for those odd jobs, like fetching five gallon pails of paint from the hardware store five miles away.

Musing instead of soldering....let's fire up that butane iron and finish this little job today, roughed in.

Repainting the frame: later, after all trials and mods are done, and the bike can be stripped down to its bare frame.

Cheers, thank you for your thoughts, pro, con or neutral,

Reid

Good points, all noted and well-taken here. Although you are not speaking specifically of this pack installation,

I'd like to note for others who wander into this page:

=The pack is not epoxy potted (nor did you imply that it were so-treated).

It is only double-wrapped now with an added layer of super-quality duct tape (that Gorilla brand stuff).

Prep for that step: the pack was scuff-rubbed with steel wool and then super-cleaned with wipings with isopropyl alcohol,

to ensure best bonding of the Gorilla brand tape. The tape applied, was then rubbed, rubbed, rubbed with a pressing cloth

between a warm, small footprint sealing iron, to fully melt and bed the thick adhesive of the new tape, to the OEM cheap quality duct tape. This, for water sealing, as too, the corners and wire exit points were also sealed with Perfect Glue (silicone)#1.

=Now, the cementing of the pack into the basket should be more or less permanent, yet, reversible if the pack

should ever need to come out. To remove the pack: I'd invert the bike for several days and see if the RTV begins to lose its grip to the scuff-rubbed bottom of the taped pack. If not, then I'd flood the area with mineral spirits or naptha, which will weaken the RTV and allow the pack to be removed (with that gravity assist of fifteen pounds of upside down PING battery.

The BMS is the only portion fully epoxy encapsulated. It is a non-servicable part, should it ever fail, yet can be swapped out easily enough if it were to fail.

The plug connector to the BMS can be disconnected in situ, which will allow manual checking of cell balances at any time in the future: that is, I can tell if ever a cell goes bad.

This type of battery is not prone to cell puffing, but if a cell were to puff at all, visual examination will reveal that fact,

and the battery pack then removed and sent in (or serviced by myself) to replace any bad cell.

------

Center of gravity: a basket mount battery pack is not ideal for nimble handling;

but then again, neither is a rider sitting tall above the saddle in non-aero stance.

Advantage of this mount: the bike still looks like a ho-hum, uninteresting single speed bike = less curiosity raised in onlookers and thieves, etc.

It will pedal normally, freewheel as any normal bike, and with its coaster brake freewheel: dead silent whilst manual pedaling/coasting.

The weight at present is sixty five pounds. The range of this 36V, 20Ah, geared front hub motor bike (no front brake)

has yet to be determined.

The fore-aft weight distribution is heavily biased to the rear, especially as it is now a sort of "crank forward" bike.

This will limit traction on wet roads or uphill climbs in mud. The only uphill of note around here is a century old rockpit

a couple of blocks away: grassy, a park now, it will be fun to bomb down its steep sides (the half city block park is about fifteen feet deep, with sloping sides all round of about 1 in 4 grade: I expect front wheel slippage when climbing out if the grass is wet.

But most all my riding will be on normally dry, paved, level roads. Headwinds, on occasion, will be the only real load against the bike;

that, and wind resistance to be expected when going more than about 15 mph.

But this is a 20 to 25mph bike.

I may want to exchange the present rear wheel cog for a smaller tooth count for easier spinning when I cover distances at 20mph or greater;

the start-up torque of the eZee will take care of the difficulty of starting off from a standing stop, as at a stop sign, etc.

I plan to use the assist for starting and for long distance, relatively high speed cruising.

I plan to leave the car at home and use the bike for local errands, with plenty of mileage range available

in case I really want to go somewhere...and yet, be able to pedal manually back home without difficulty....so long as there's no headwind.

Living in a flat area really simplifies this bike design. I just don't need multiple gearing: the assist function sort of takes there place (because we have no hills).

IF I lived with various slight to moderate grades, as most of you have, this cruiser concept would not be so nifty.

But as it is, I think I have an ideal formula for my needs: a bike that still looks all-bike without odd additions which only

put off the general public against wanting an ebike.

A year from now all this will be obsolete, as ebikes for light duty already are on the market, looking as bike-like as can be;

but will they go as far and as robustly as this all-steel bike?

I plan to hop curbs with ease (so little weight at the front of the bike) and take air as much as possible

and never break a spoke or bend a rim: Big, soft, Big Hanks, 2.5" are my primary shock absorbers.

The chainwheel has already been exchanged from a 48T (I forget) to a 52T, the largest readily available.

The bike trailer is ready too for those odd jobs, like fetching five gallon pails of paint from the hardware store five miles away.

Musing instead of soldering....let's fire up that butane iron and finish this little job today, roughed in.

Repainting the frame: later, after all trials and mods are done, and the bike can be stripped down to its bare frame.

Cheers, thank you for your thoughts, pro, con or neutral,

Reid