MarkJohnston

10 kW

- Joined

- Mar 25, 2021

- Messages

- 620

markz said:What about dual brakes?

One method is dual disc brakes, to help ease the heat buildup.

Needs to have flanges on either side of the hub, more costly.

Could do that front and rear.

Also use quality disk pads from a known entity (bike store) not generic pads and not from an unknown source like most of the sellers on alibaba/aliexpress, as those could be counterfeit.

Another method is to have a lever activating two cables, disk + vbrake. I had some cheap levers with two cable mounts, but there is also stuff you can buy for regular levers that split the cable into two.

It was to finicky for my liking. Problem Solvers might have something.

I literally have rid 2 days in a row with no brakes, only eabs low on a dd hub, front. You hook it up to the Wuxing levers, or check out Grintech.

https://ebikes.ca/shop/electric-bicycle-parts/ebrakes.html

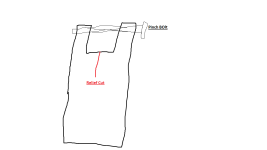

Hehe. I think I have the rims to run two front brakes at once. The hydraulic lever is the issue

![PXL_20211027_073628733[1].jpg](/sphere/data/attachments/172/172293-a9b03e6557ce9098d3e34ef3b87d363d.jpg)