MOTOR UPGRADE .....

This is my motor upgrade from stock 5403 to QS 205.

I chose the extra/V3 type with winding 30X4T 11.39kV hoping it will deliver a good amount of torque without overheating.

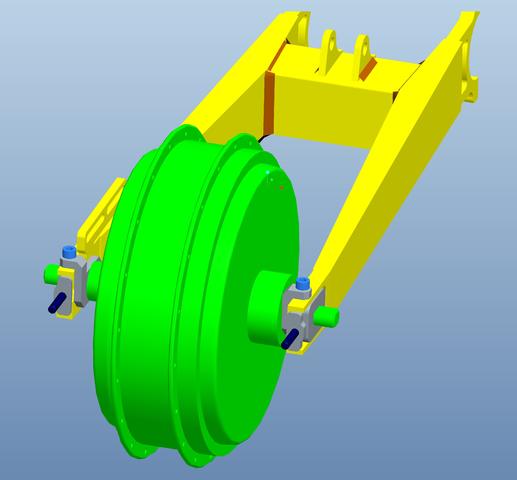

To center the motor in the swingarm I need a spacer of 5.5mm on the left side and one of 7.2mm on the right.

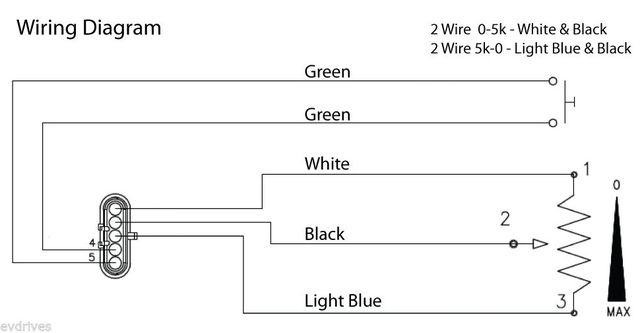

My idea was to prolong that plates on the swingarm so they will work as torque plates when the light blue bolts are tightened.

I will need to build also two new plates on the outer side of the swingarm because the QS205 motor shaft has a M16 thread.

This is the tightening procedure that I designed:

First of all I need to adjust the position of the motor for the correct chain tension, then tighten the two light blue bolts (at this point the shaft of the motor is blocked in the swingarm and can not rotate backward) the last thing is tightening the nuts on the motor shaft.

Once the shaft is locked in a regenerative braking position when regenerative brake is applied the reaction torque is provided by the swingarm.

Mounting QS205 motor ...

I'm pleased with how it turned out motor assembly in the swingarm.

The torque plates works as expected and the motor is centered better than the stock 5403.

There are two potential problems that bother me, the first is that the brake disc bolts may rub on the large bunch of wires coming out from the shaft and the second is the little distance that there is between the brake caliper and the left side of the motor. The gap is about 1mm.

For the brake disc bolts I thought to countersink the holes in the brake disk to house the flat-head screws.

The brake disc will be mounted with a carbon disc of 1mm thickness that flush the recess of 1mm in the center of the brake disc and I will use the brake disc spacer provided with the motor.

Countersink the disc brake holes:

Tried to mount this 2.3mm thick disc spacer :

But reducing the clearance between swingarm and disc is not a good idea.

So I went back to the first 1mm thick disc spacer and also I filed the edge of the screws in the center near the shaft.

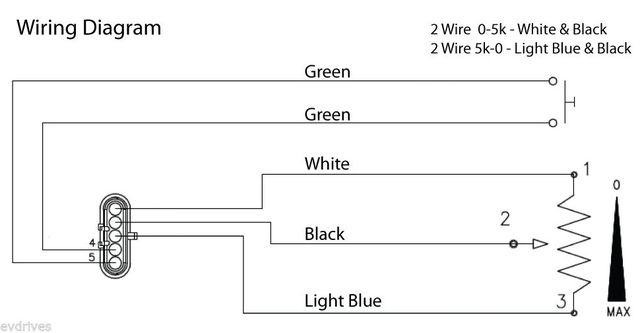

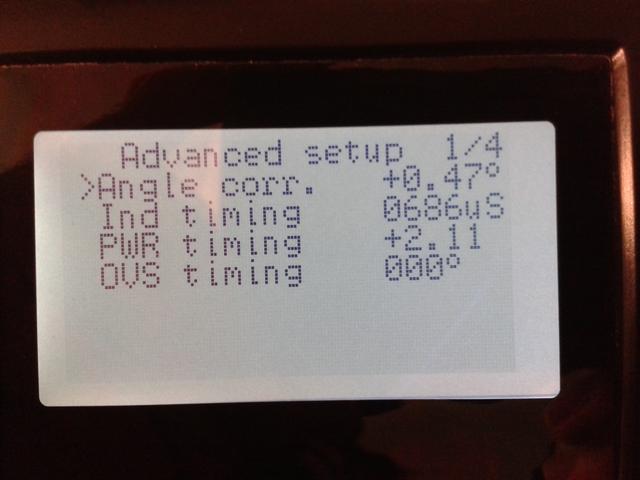

This is what I'm going to use to do Adaptto autodetect then I will open the motor and will remove the spare set of halls/thermo wires provided with the motor.

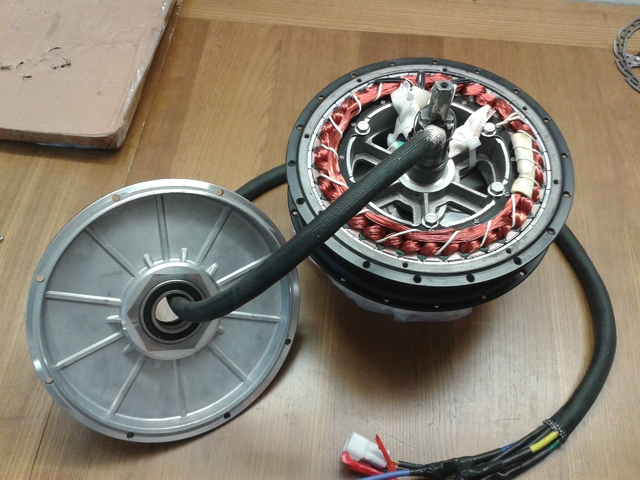

After motor autodetect done for both the main and spare halls sets all went in the correct way and now I will open the motor to remove the spare set of halls wires to see if is possible to use the motor on the Bomber swingarm without wrecking halls and phase wires.

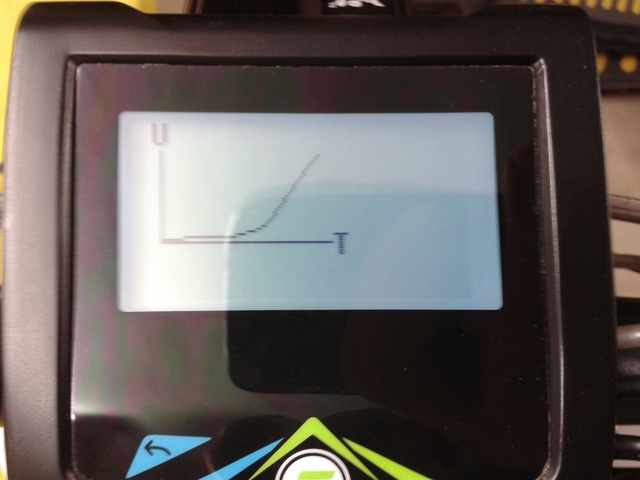

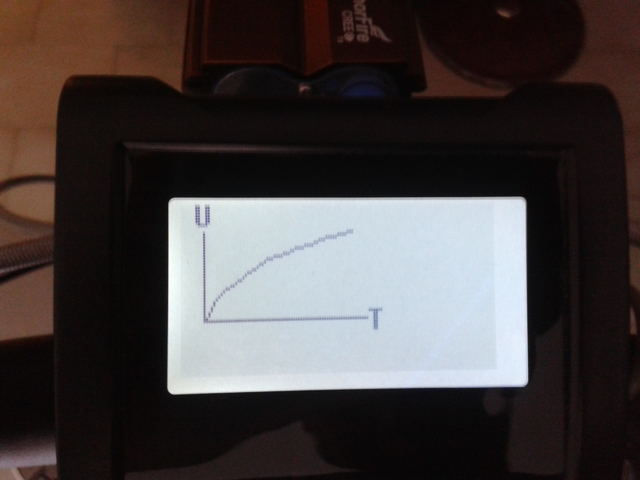

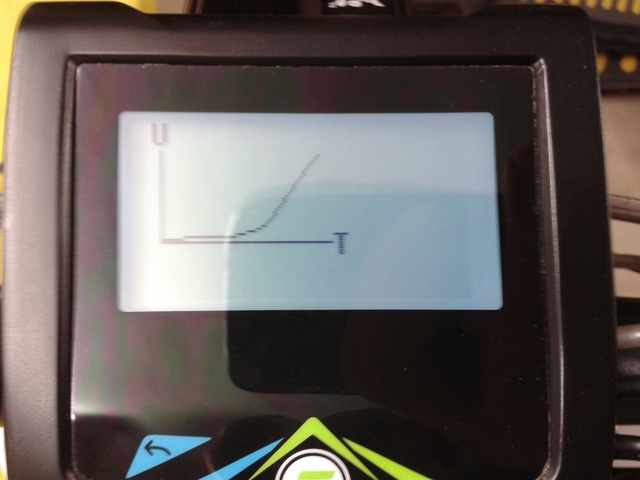

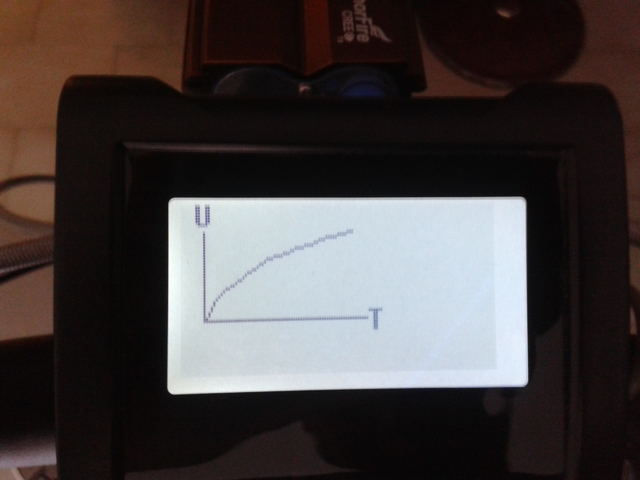

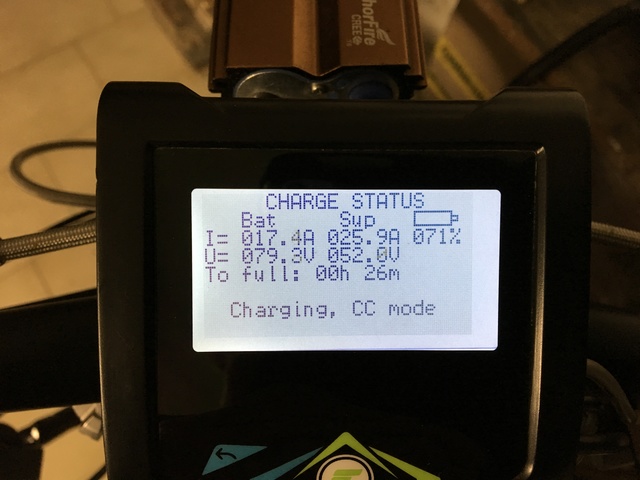

This is what I have just after the first autodetect:

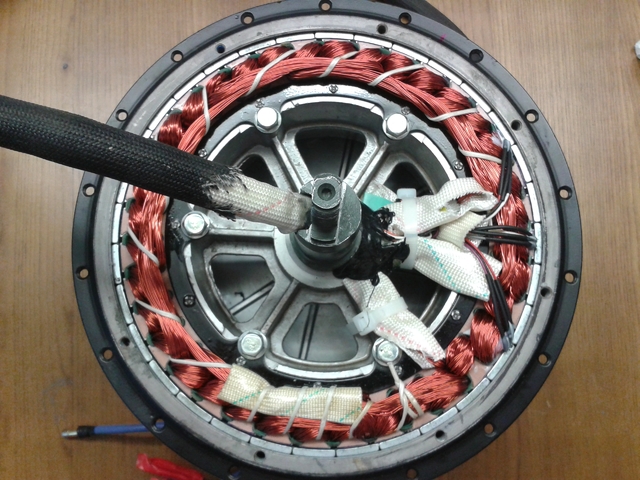

Motor opened:

Bearings look good:

Here are all the parts finished.

This is what I have built to protect the phase and halls wires from rubbing on the brake disc bolts:

It seems to me that I can try to ride this way:

These are the torque arms painted:

Wheel finished with trial tyre Vee Rubber VRM021:

Weight of the entire wheel 17,7Kg

Diameter 624mm

A comparison between 5403 with motocross tyre and QS205 with trial tyre both with 19" rim:

This is what the Bomber looks like with QS 205:

And this is how I managed to route the phase wires to avoid rubbing on V-boxx gear selector sheath