Cyclomania

10 kW

Hi

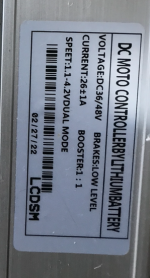

So I am trying to put a backmotor-wheel on a bike-frame that I have. 28 wheels. I have a sw900 display available and the controller I have has the metrics as in the screenshot here.

The battery is a 36 volt battery from an old bike I had. I am now trying to see if they are all going to work with each other.

Now I put the gas throttle on it and try to make the wheel spin. See video:

Any idea why it only makes this sound? What should I do to make it work?

Thanks

So I am trying to put a backmotor-wheel on a bike-frame that I have. 28 wheels. I have a sw900 display available and the controller I have has the metrics as in the screenshot here.

The battery is a 36 volt battery from an old bike I had. I am now trying to see if they are all going to work with each other.

Now I put the gas throttle on it and try to make the wheel spin. See video:

Any idea why it only makes this sound? What should I do to make it work?

Thanks