casainho said:Lid magnet

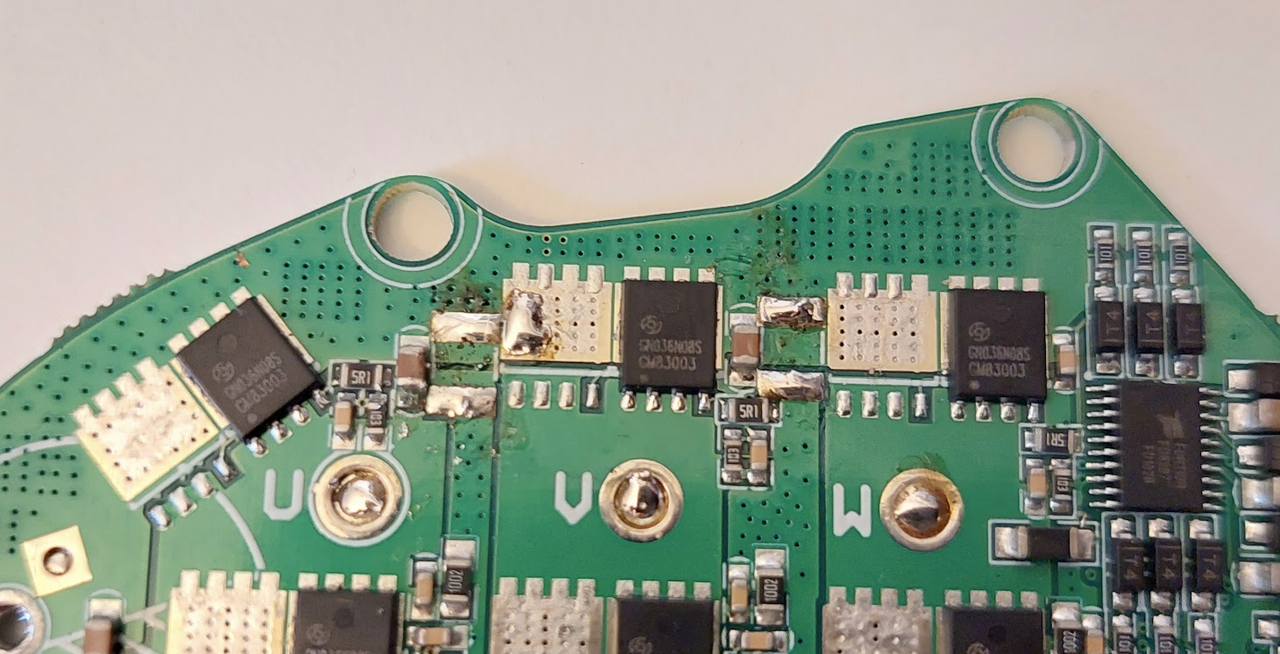

What is that for inside the motor??

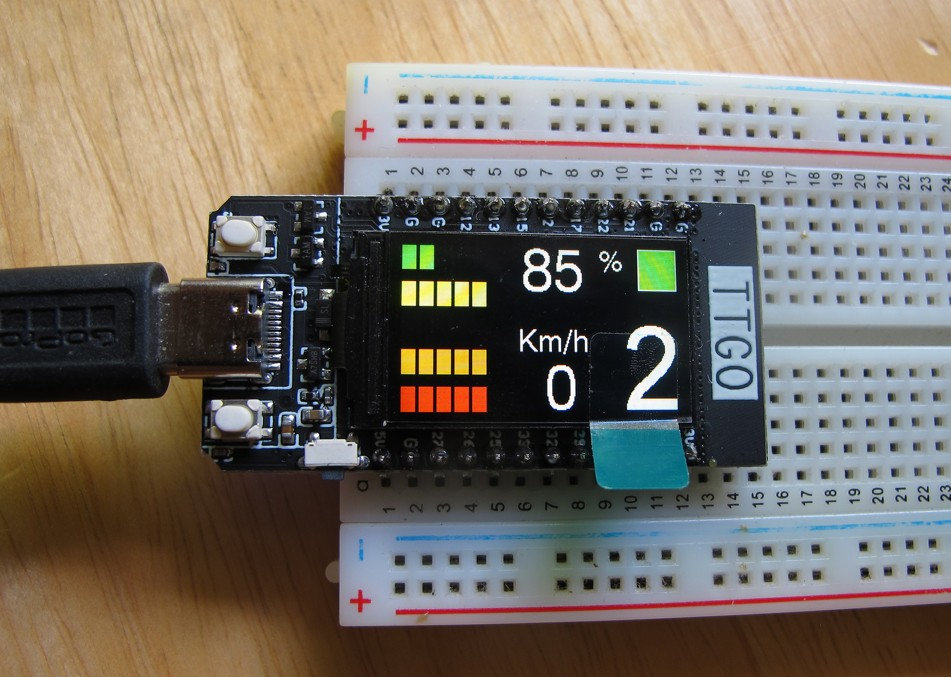

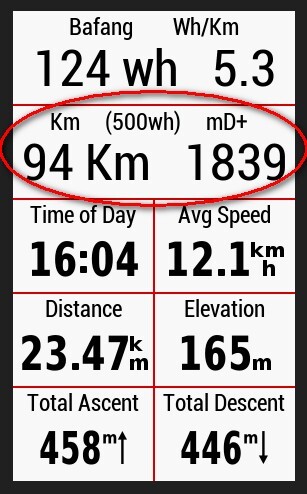

Custom OpenSource firmware

Does anyone at least were able to connect JTAG and flash firmware on the FS32K142 microcontroller??

I believe we discussed this previously and I bought a couple of the recommended dongles/connector to try it, but then wound up putting my bike back together to ride! Then life got crazy, and here we are months later!

I will take a look over the weekend and see what I can get set up. You were originally looking for a download of the existing firmware (though again, I caution that I have the 'lousy' version, not the better version installed.) is that still the case?

It seems almost that the ultimate solution is to build a VESC controller into a package / shape which will fit in the original M500/600 slot? ...essentially an open source Luna V2 controller? This would avoid the complicated firmware of bafang and instead use the open firmware of VESC, and if the board was DIY or open source, would also avoid the Luna 'embargo' on selling aftermarket V2 controllers?